Dual-effect filter material for removing dust and decomposing dioxin and preparation method thereof

A filter material and dioxin technology, applied in the field of dust removal and dioxin decomposition double-effect filter material and its preparation, to achieve low running resistance, prevent breakage and loss, and improve catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

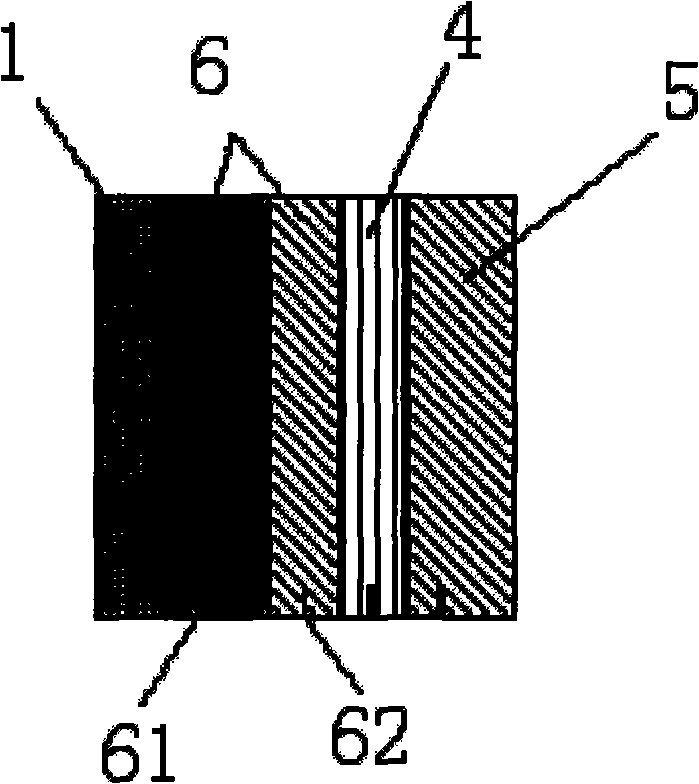

[0038] A double-effect filter material for dust removal and dioxin decomposition, such as figure 1 As shown, it includes a dust-facing surface 1, a supporting catalytic layer 6, a base cloth layer 4 and a supporting layer 5, and the dust-facing surface 1 is covered on one side of the supporting catalytic layer 6; one side of the base cloth layer 4 is placed on the supporting catalytic layer The other side of 6 and the other side of the base cloth layer 4 are placed on the supporting layer 5; the supporting catalytic layer 6 is composed of a catalytic layer 61 superimposed on a catalytic supporting layer 62. The dust-facing surface 1 is covered on the catalytic layer 61 . The base cloth layer 4 is placed on the catalytic support layer 62 .

[0039] The preparation method of the above-mentioned double-effect filter material for dust removal and dioxin decomposition comprises the following steps:

[0040] a, preparation of support layer and catalytic support layer

[0041] The p...

Embodiment 2

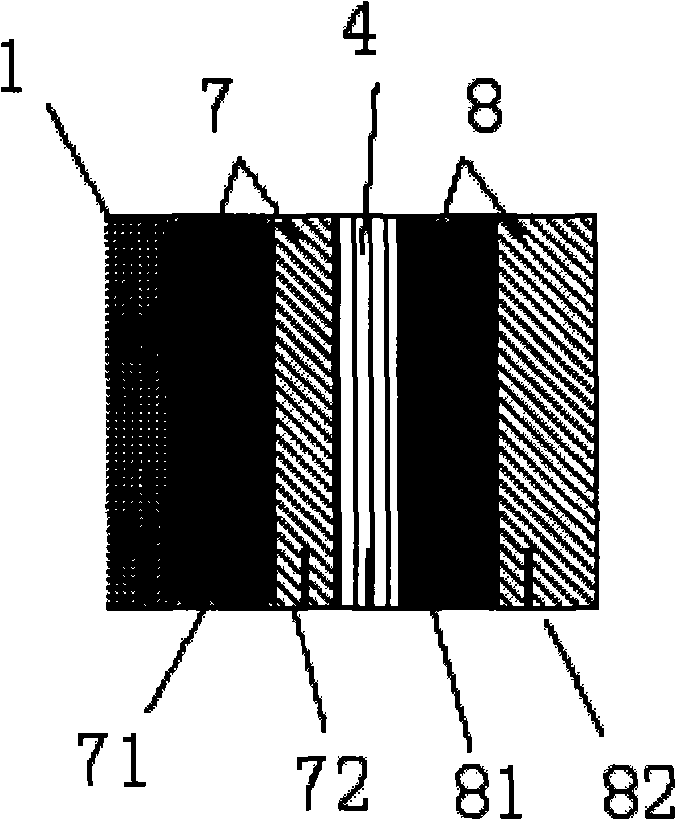

[0052] Another dust-removing and dioxin-decomposing double-effect filter material, the support layer is replaced by a support catalyst layer. Such as figure 2 As shown, it includes a dust-facing surface 1 , a supporting catalytic layer 7 , a supporting catalytic layer 8 and a base cloth layer 4 . The supporting catalytic layer 7 and the supporting catalytic layer 8 are respectively located on both sides of the base cloth layer 4 . The supporting catalytic layer 7 is composed of a catalytic layer 71 superimposed on a catalytic supporting layer 72 , and the supporting catalytic layer 8 is composed of a catalytic layer 81 superimposed and covering on a catalytic supporting layer 82 . The dust-facing surface 1 is covered on the catalytic layer 71 supporting the catalytic layer 7 .

[0053] The preparation method of the above-mentioned double-effect filter material for dust removal and dioxin decomposition comprises the following steps:

[0054] a. Preparation of catalytic supp...

Embodiment 3

[0066] Another kind of dedusting and dioxin decomposition double-effect filter material, structure is identical with embodiment 2, as figure 2 shown.

[0067] In the preparation method, after acupuncture, the filter material is impregnated with polytetrafluoroethylene emulsion and baked at a temperature of 260° C. for 10 minutes, and the rest of the processing is the same as in Example 2.

[0068] The dust removal and dioxin decomposition double-effect filter material with a gram weight of 1750 g / m2 obtained by the above method has a removal rate of 99% for dioxins at 200°C, and a removal efficiency of 99.9% for particles above 5 microns. The resistance is 1500Pa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com