Non-full pipe flow measurement method of conductive fluid

A flow measurement, conductive fluid technology, applied in the direction of fluid velocity measurement, application of electromagnetic flowmeter to detect fluid flow, volume/mass flow generated by electromagnetic effect, etc., can solve the requirement of constant fluid conductivity and other problems, to achieve a simple and reliable measurement method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

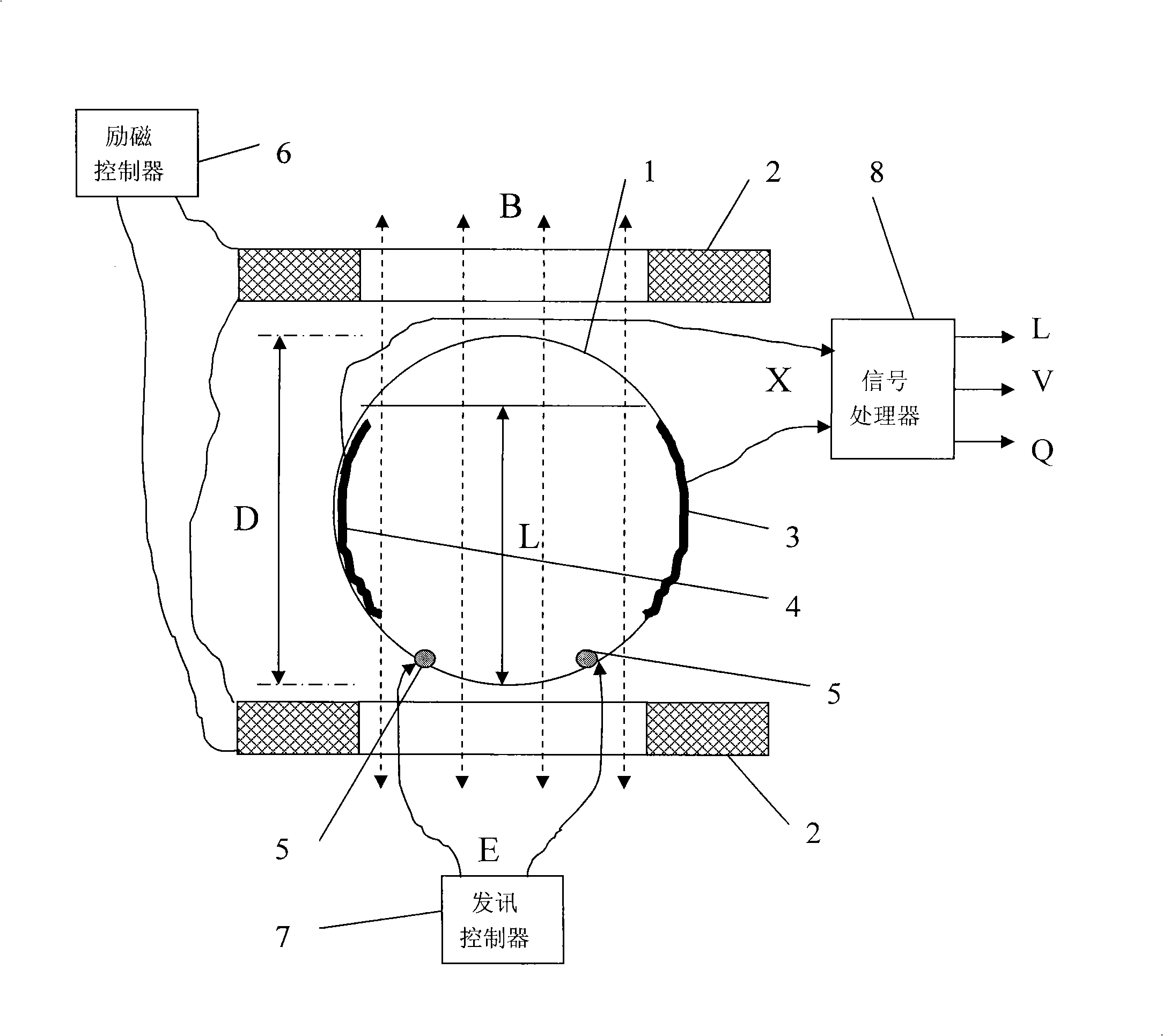

[0026] A preferred embodiment of the present invention is as follows: see figure 1 .

[0027] A method for measuring the flow rate of a conductive fluid in a partially filled pipe. The measurement setup includes a measuring tube 1 with a diameter D and an insulating inner tube wall, an excitation coil 2 outside the measuring tube 1, and measuring signals on both sides of the inner wall of the measuring tube 1. Electrode unit 3 and measuring electrode unit 4, a pair of transmitting electrodes 5 on the inner wall of measuring tube 1 lower than measuring electrode unit 3 and measuring electrode unit 4, an excitation controller 6 for controlling the magnetic field B of excitation coil 2 1. A signaling controller 7 that controls the potential E on the signaling electrode 5. There is a fluid flowing along the pipeline axis in the measuring tube 1 with a liquid level L and an average flow velocity V; it is characterized in that it only passes through the signaling electrode unit 3 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com