A measuring method and device during the processing of annular semi-closed thin-walled parts

A technology for thin-walled parts and processing processes, applied in metal processing equipment, measuring/indicating equipment, metal processing machinery parts, etc., can solve the problems of unmeasurable wall thickness, affecting processing quality, low efficiency, etc., and achieve simple and reliable measurement methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, design of the present invention is further elaborated:

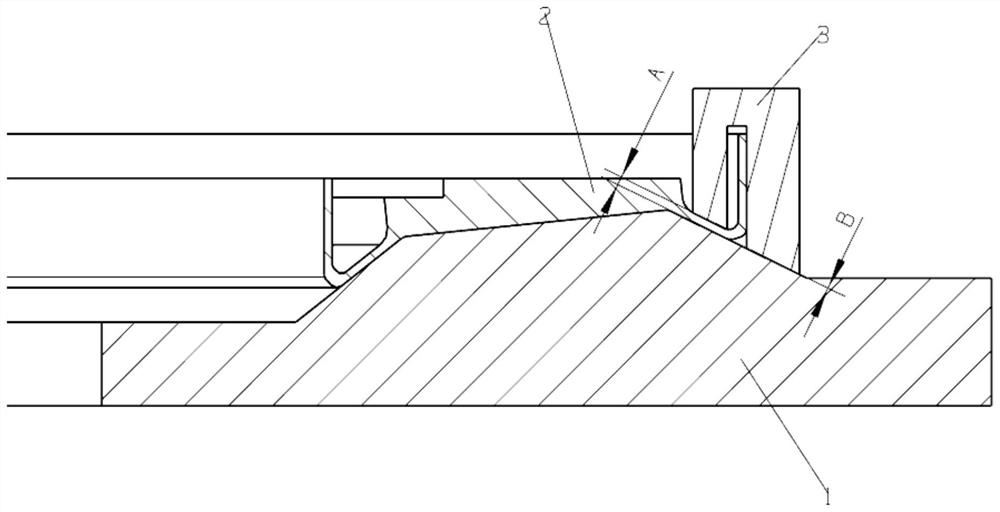

[0022] like figure 1 As shown, in view of the characteristics of the part 2 and the fixture main body 1, the present invention realizes the real-time measurement of the wall thickness by measuring the distance between the inner surface extension surface and the outer surface extension surface of the part to be measured.

[0023] Specifically, an extension surface parallel to the inner surface of the part to be measured is established on the outside of the annular semi-closed area of the part to be measured by the measuring clamp 3 . The measuring clamp 3 includes a contact surface for bonding with the inner surface of the part to be measured, and a comparison surface located on the outside of the part to be measured, the contact surface is a plane or a curved surface, and its shape is consistent with the inner surface of the part to be measured; the comparison surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com