Three-cylinder coal cutter

A shearer and three-drum technology, applied in cutting machinery, earthwork drilling and mining, etc., can solve the problems of poor adaptability to coal seam changes, reduce the total power of the shearer, and reduce the level of electrical equipment, etc., to achieve an increase in the adaptability of the coal seam, Reduced power, the effect of total power reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

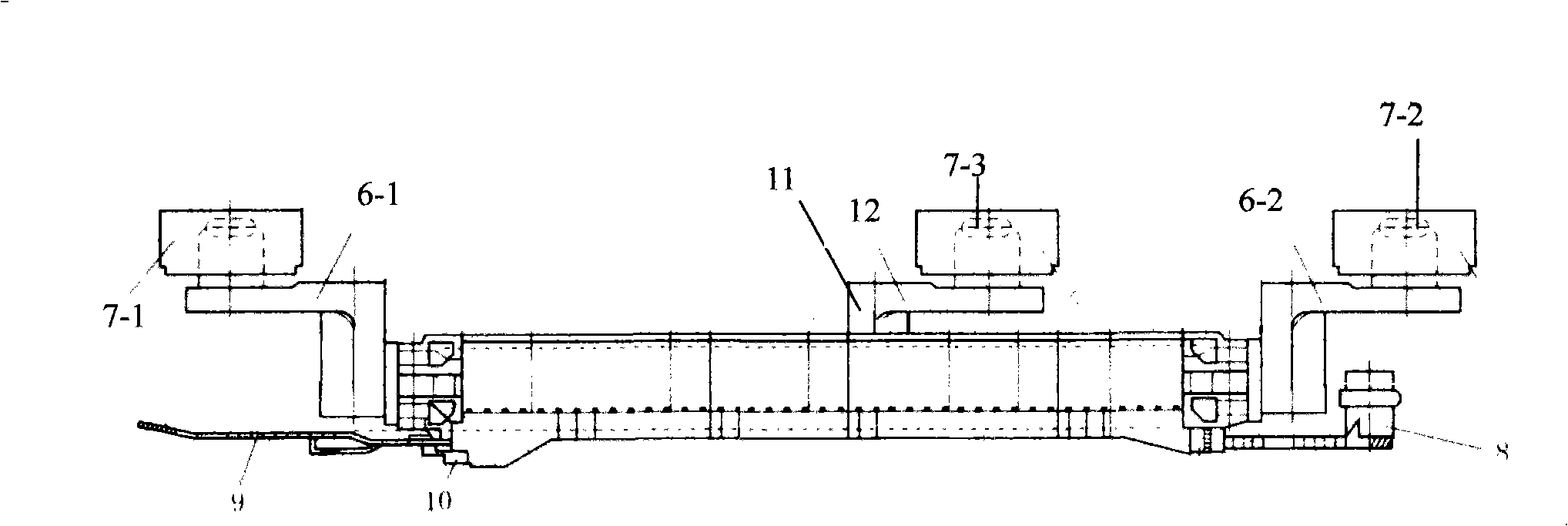

[0020] Below, with reference to the accompanying drawings, the specific implementation manners of the present invention will be further described in detail.

[0021] Among them, 1-electrical part with transformer; 2-hydraulic part; 3-traction part; 4-external traction gearbox; 5-supporting bracket; 7-2, 7-3-drum; 8-crusher; 9-shearer cleaner; 10-cable drag frame; 11-middle cutting motor; 12-middle rocker arm; 13-middle cutting motor 11 fixed Shell, 14-middle part cutting motor 11 shell and other casing butt joint holes, 15-middle part cutting motor seat, 16-middle part cutting motor 11 is fixed on the bolt that adopts on the shell.

[0022] The overall structure of the present invention is basically the same as that of the double-drum shearer, and the preferred implementation mode is the mode described in Fig. 1, 2 and 3:

[0023] That is, the middle cutting part is added on the original double-drum shearer, mainly including the middle cutting motor 11, the middle rocker arm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com