Solid tasteless odorless acid agent for textile dyeing and finishing process

An organic acid and textile technology, applied in textiles and papermaking, dyeing, fiber treatment, etc., can solve problems such as inconvenient transportation, unclean cleaning, safety issues, etc., save storage space and transportation costs, and facilitate transportation and use , the effect of favorable environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

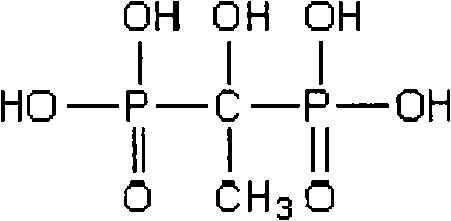

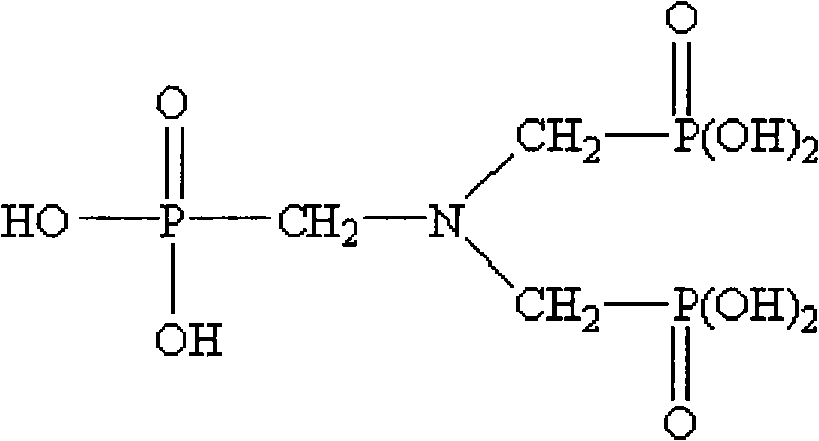

Method used

Image

Examples

Embodiment 1~6

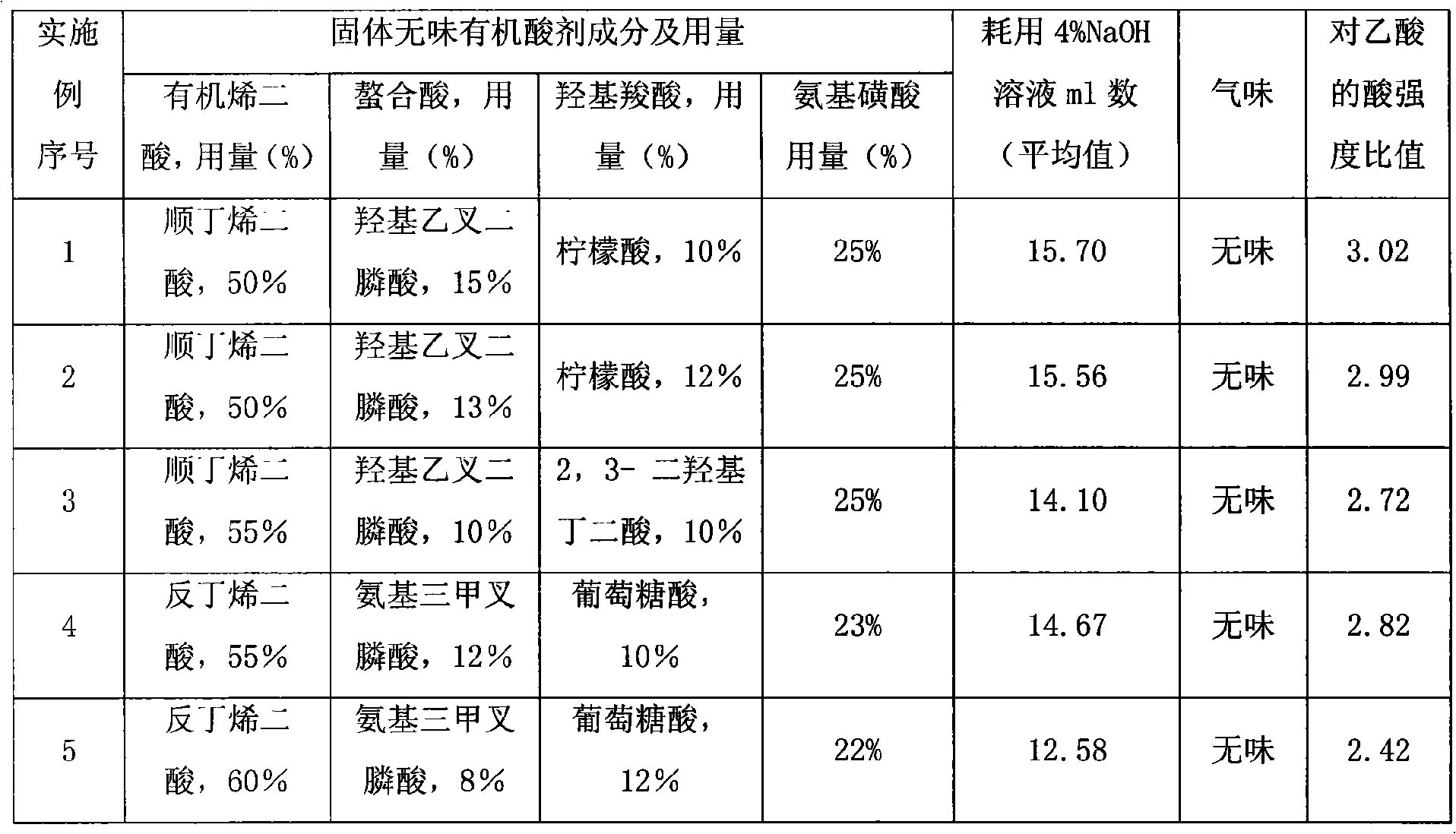

[0057] Preparation of solid odorless organic acid agent: each component and its dosage in the formula in the following table 1, add the double helix powder mixer in turn during preparation, add the materials, stir and mix for 40 minutes, and then discharge evenly.

[0058] Different embodiments of table 1 and comparison example with acetic acid intensity

[0059]

[0060]

[0061] Note: Compared with the strength of acetic acid, the experimental method:

[0062] 1) Weigh 10ml of odorless solid organic acid and 10ml of acetic acid into two clean beakers, add 90ml of distilled water respectively, mix well, and draw 10ml of the solution in the above beakers into two Erlenmeyer flasks respectively.

[0063] 2) Add 100ml of distilled water and 1ml of bromophenol blue to each Erlenmeyer flask as indicators, and then titrate with 4% NaOH solution to the end point.

[0064] 3) Do parallel experiments five times and take the average value

[0065] As can be seen from Table 1, the...

Embodiment 7

[0067] Embodiment 7 application test

[0068] The effectiveness of the solid odorless organic acid of the present invention compared to acetic acid is illustrated using post-bleach neutralization tests.

[0069] experimental method:

[0070] 1) Fabric: 32-count pure cotton knitted fabric

[0071] Bleaching process formula: 30% H 2 o 2 5.0ml / l

[0072] 40% NaOH 2.0ml / l

[0073] 100% scouring agent LFD (Koning Germany) 0.35g / l

[0074] Organic Complexing Agent 540 (Germany Corning Company) 0.35g / l

[0075] Conditions: bath ratio 1:15, bleaching at 95°C for 45 minutes

[0076] 2) Wash the fabric in water at 40°C for 4 minutes after bleaching, neutralize the organic acid agent (20% chemical conversion) and 20% acetic acid to pH=7 (five times in parallel, average value) obtained from Examples 1 to 6 respectively

[0077] 3) Consumption of neutralizing acid agent (ml) is shown in Table 2:

[0078] Table 2 Application effect comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com