Piping for air conditioner outdoor machine

An air conditioner outdoor unit and piping technology, applied in refrigerators, fluid circulation arrangements, refrigeration components, etc., to eliminate mechanical resonance, improve fatigue life, and reduce power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

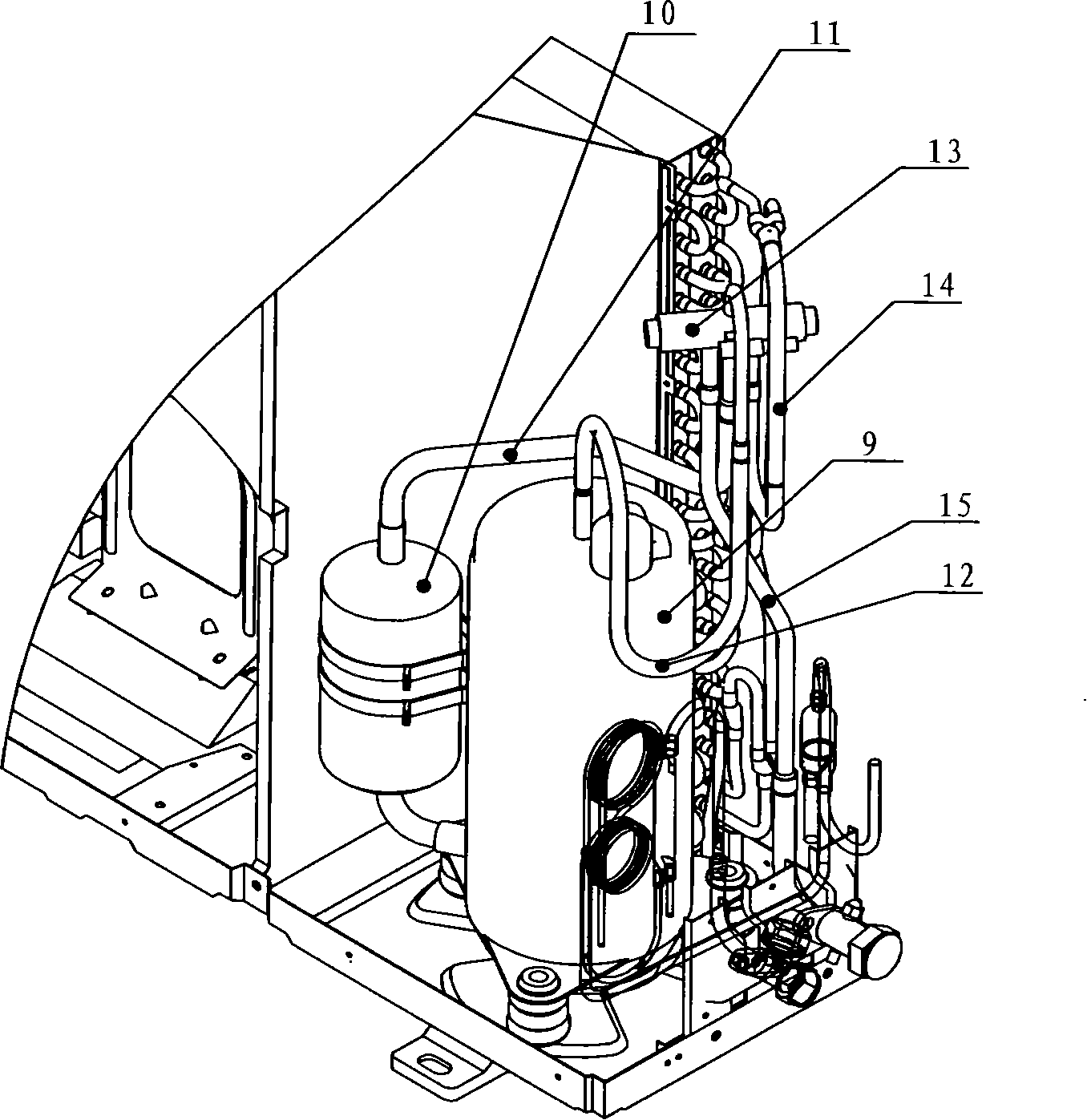

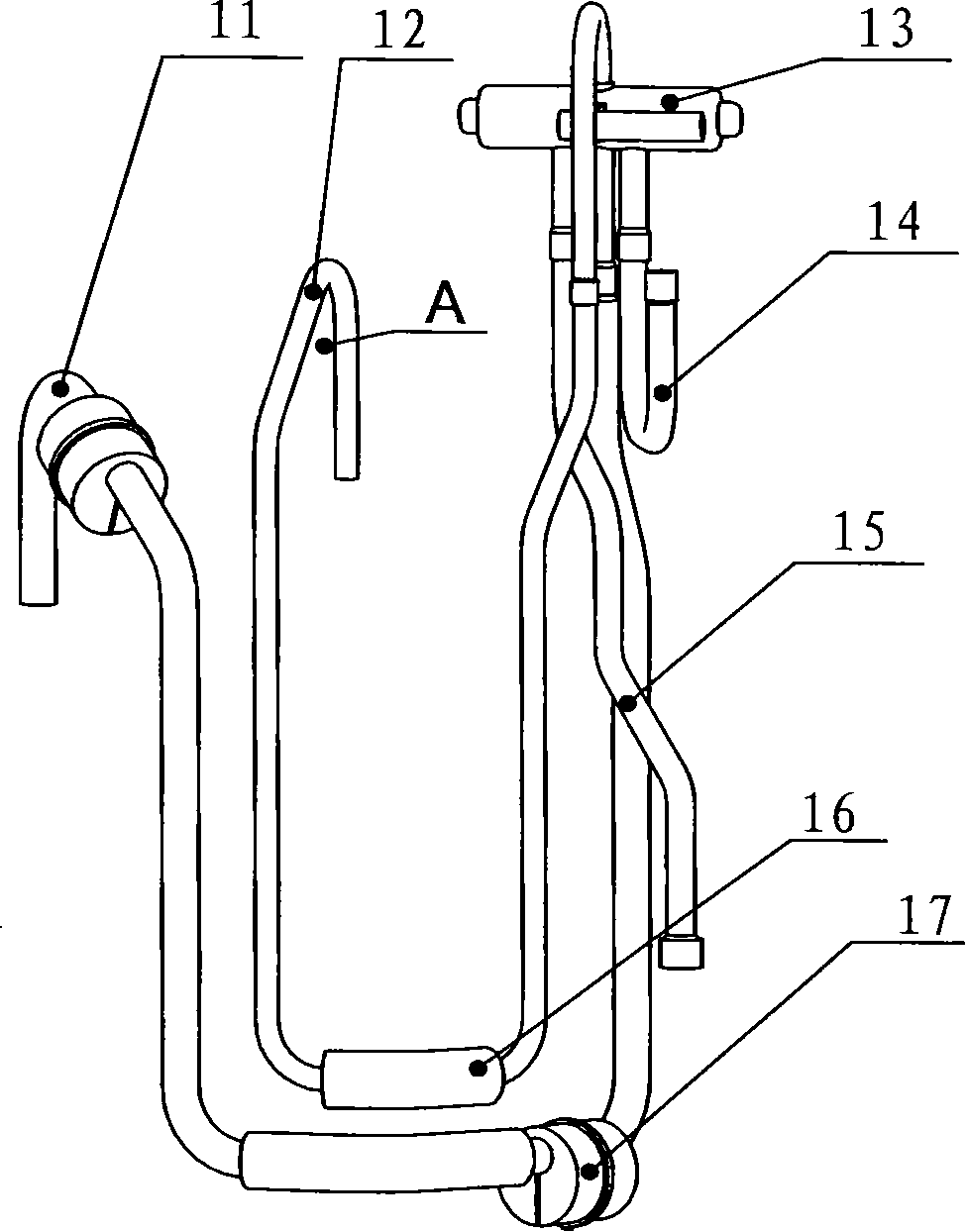

[0030] as attached figure 1 Shown is the application of the piping provided by the present invention in the outdoor unit of the air conditioner. One end of the exhaust pipe 12 is connected to the exhaust port of the compressor 9, the other end is connected to the four-way valve 13, the condenser connecting pipe 14 connected to the four-way valve 13 is connected to the condenser, and the low-pressure valve connecting pipe 15 is connected to the low-pressure valve. In addition, one end of the air return pipe 11 is connected with the four-way valve 13 , and the other end is connected with the air return port on the liquid storage tank 10 of the compressor 9 .

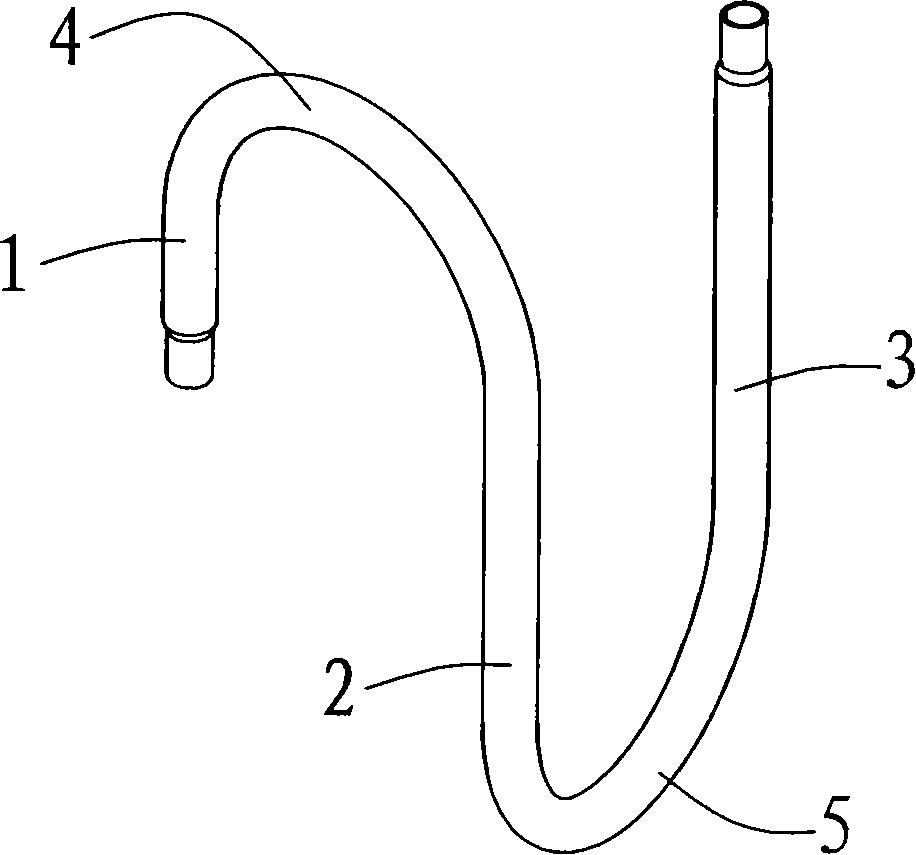

[0031] as attached Figure 3a , Figure 4 , Figure 5 , Figure 9 As shown, the exhaust pipe 12 includes a front section 1 perpendicular to the compressor exhaust port, a middle section 2 that changes the flow direction, and a rear section 3 connected to the four-way valve, the front section 1 and the middle section 2...

Embodiment 2

[0035] as attached Figure 3b , Image 6 As shown, the difference between Embodiment 2 and Embodiment 1 is that the front connecting section of the exhaust pipe 12 adopts two circular arc segments 4a, 4b and a straight pipe segment 4c with a small bend radius and tangential to replace the semicircular arc pipe 4, To prevent the exhaust pipe from being too high and collide with the electric control board during the air conditioner drop or transportation; the semi-circular arc pipe 5 is still used in the rear connection section. That is to say, the end of the exhaust pipe 12 connected to the compressor 9 is replaced with a semi-circular arc pipe with a smaller bend radius and a straight line to prevent the exhaust pipe 12 from being too high and colliding with the electric control board during falling or transportation; The end connected to the four-way valve 13 adopts a large semi-circular arc to slow down the impact of the high temperature and high pressure refrigerant pulsat...

Embodiment 3

[0037] as attached Figure 3c , Figure 7 As shown, the difference between Embodiment 3 and Embodiment 1 is that: the front connecting section of the exhaust pipe 12 adopts a semicircular arc pipe 4, and the rear connecting section adopts two sections of circular arc sections 5a, 5b with small bend radius and tangent And the straight pipe section 5c replaces the semicircular arc pipe 5. This design is mainly to provide a larger assembly space for high-pressure valve components. The exhaust pipe 12 adopts a semi-circular arc at the end connected to the compressor 9, while the end connected to the four-way valve 13 adopts a smaller elbow radius and a straight line. segment instead.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com