Vibratory Hammer Adjustable Eccentric Moment Drive Unit

A technology of eccentric torque and driving unit, which is applied in construction, sheet pile walls, foundation structure engineering, etc., can solve the problems of increasing the starting load of the motor, delaying the starting speed of the vibratory hammer, and reducing the safety performance of the vibratory hammer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

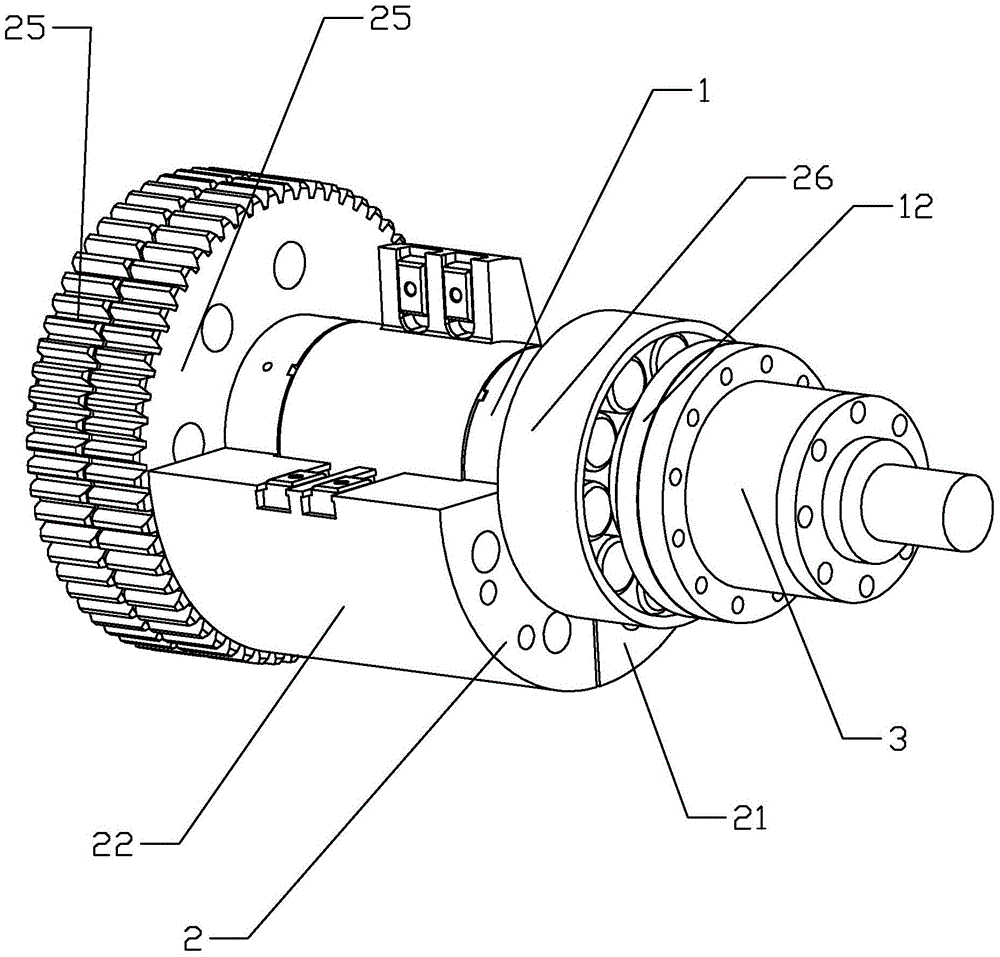

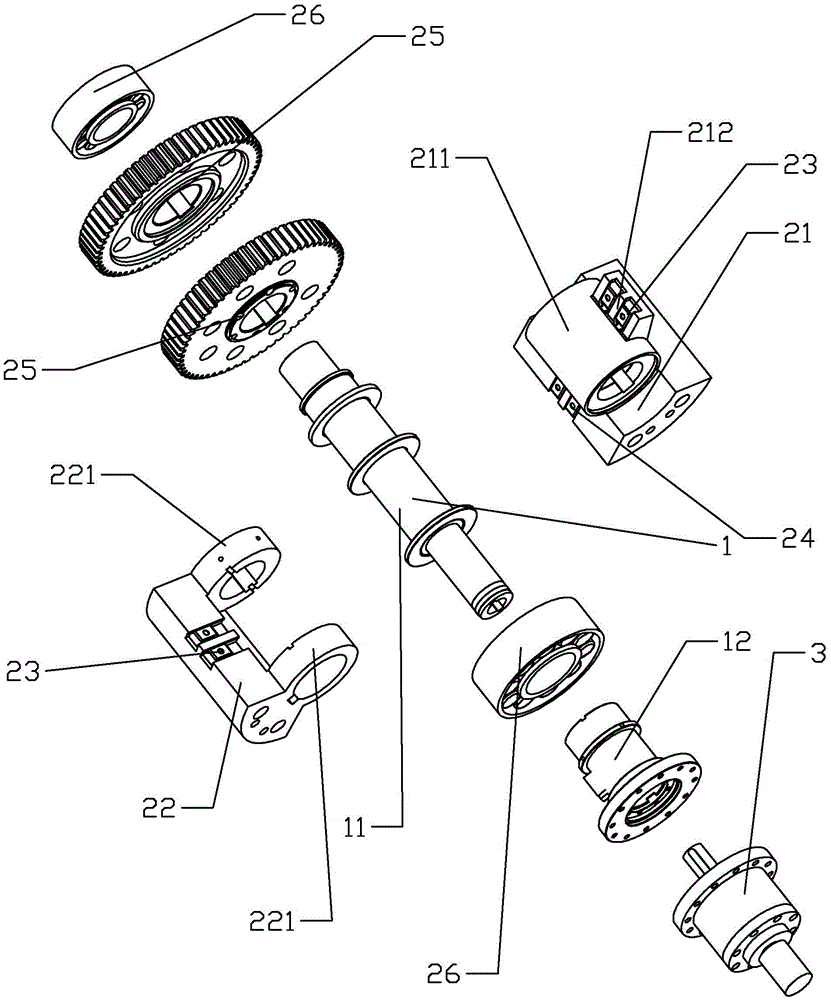

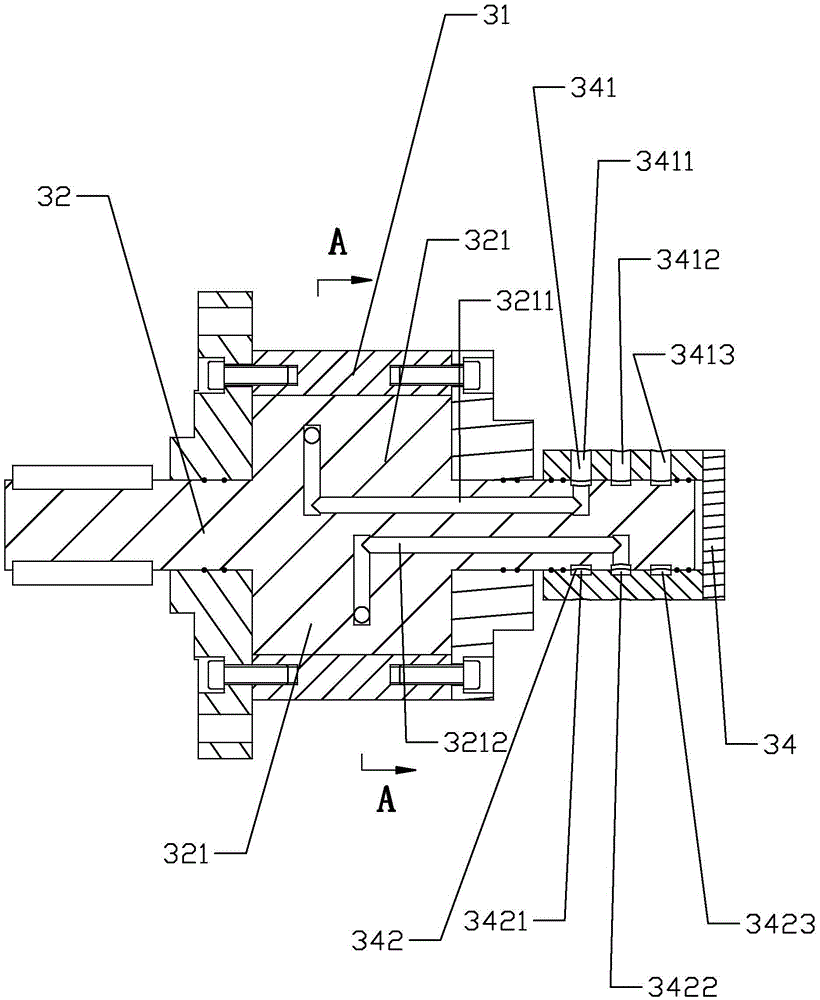

[0027] Such as figure 1 — Figure 5 As shown, the present invention discloses an adjustable eccentric moment drive unit for a vibratory hammer, which includes a rotating shaft 1 driven by a motor, and an eccentric block 2 that rotates synchronously is sleeved on the rotating shaft 1, and the eccentric block 2 includes circumferentially arranged The first eccentric weight 21 and the second eccentric weight 22 are also provided with a distance adjustment mechanism 3 for adjusting the circumferential distance between the first eccentric weight 21 and the second eccentric weight 22 on the rotating shaft 1, such as Figure 5 As shown in the working state, use the distance adjustment mechanism 3 to transfer one of the eccentric blocks to the top of the rotating shaft 1 and set it opposite to the eccentric block of the other rotating shaft before the rotating shaft is started, so that the overall center of gravity of the two is aligned with the rotating shaft 1 Overlapping, the ecce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com