Vibration hammer adjustable eccentric moment drive assembly

A technology of eccentric moment and drive assembly, applied in the direction of rotational vibration suppression, inertia force compensation, sheet pile wall, etc., can solve the problems of reducing the safety performance of the vibrating hammer, increasing the starting load of the motor, and the starting speed and impact of the vibrating hammer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

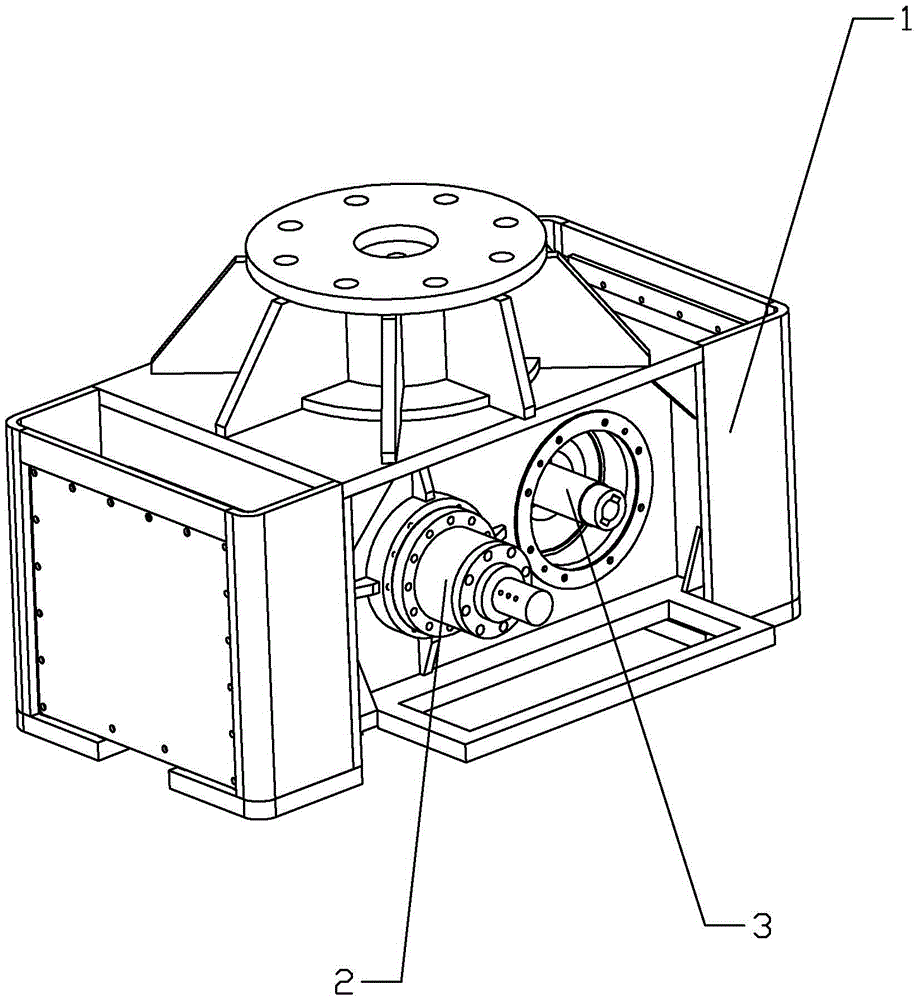

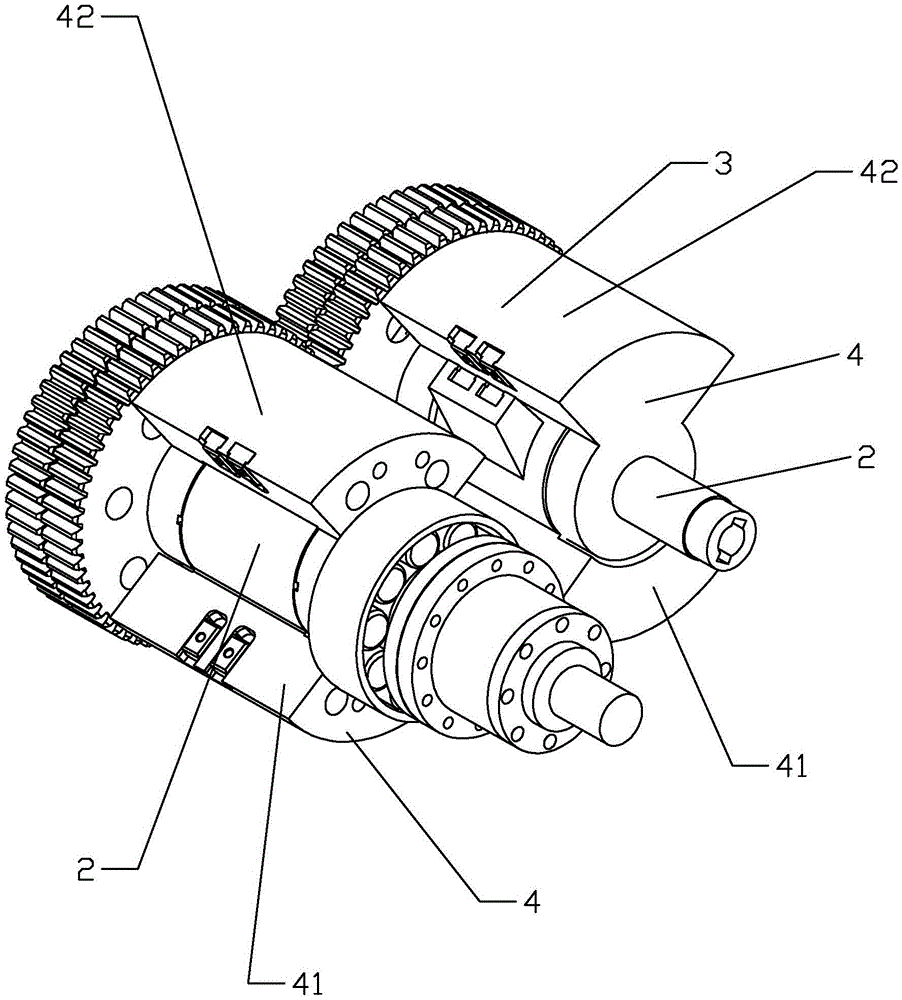

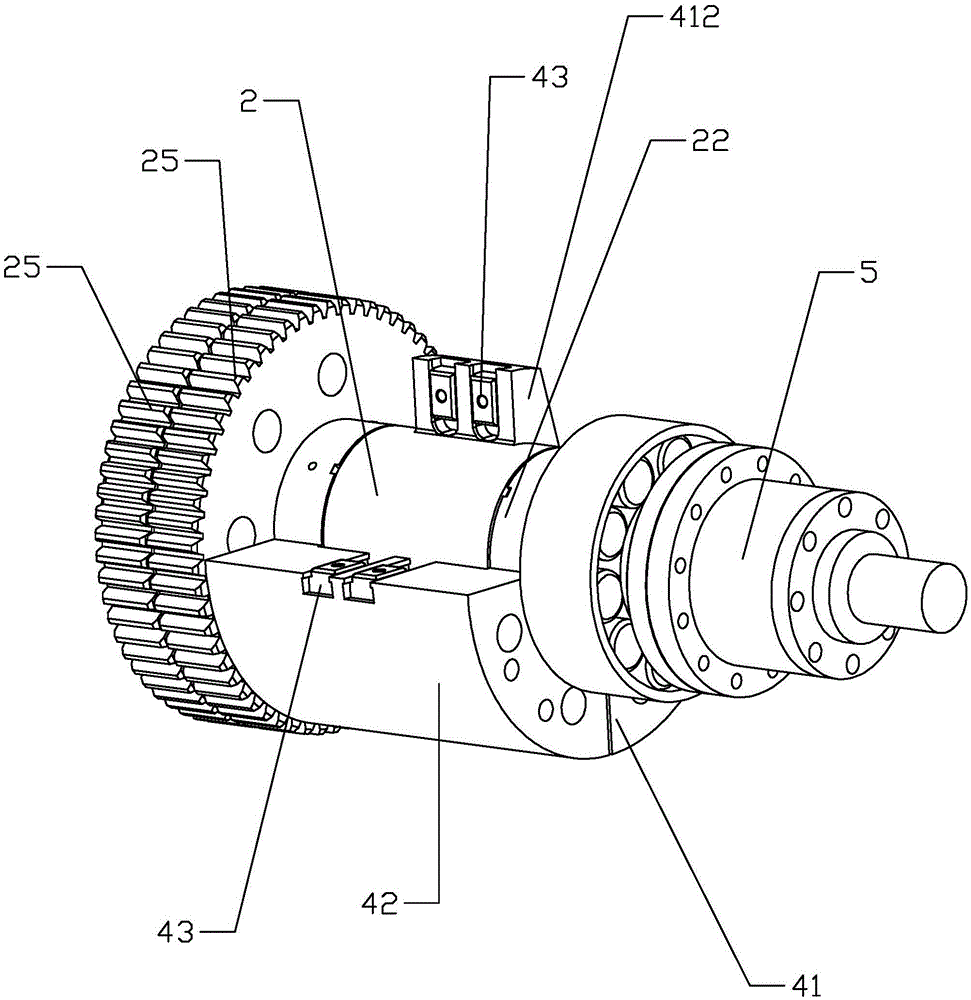

[0028] like figure 1 — Image 6 As shown, the present invention discloses a vibratory hammer adjustable eccentric moment drive assembly, which includes a vibratory hammer housing 1 and a main rotating shaft 2 and an auxiliary rotating shaft 3 arranged on the vibrating hammer housing 1 for linkage, the main rotating shaft 2 Driven by a motor, the rotation speed of the main rotating shaft 2 and the auxiliary rotating shaft 3 are the same and the direction of rotation is opposite. The main rotating shaft 2 and the auxiliary rotating shaft 3 are respectively sleeved with eccentric blocks 4 that rotate with the shafts. The eccentric blocks 4 include circumferential Arranged first eccentric mass 41 and second eccentric mass 42, the first eccentric mass 41 of the main rotating shaft 1 and the first eccentric mass 41 of the auxiliary rotating shaft 2 rotate synchronously, and the second eccentric mass of the main rotating shaft 1 42 and the second eccentric block 42 of the auxiliary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com