Mould for processing glass container

A glass container and mold technology, applied in glass production and other directions, can solve the problems of easy deformation of molds and short service life, and achieve the effects of increasing production capacity, ensuring service life, and accelerating heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

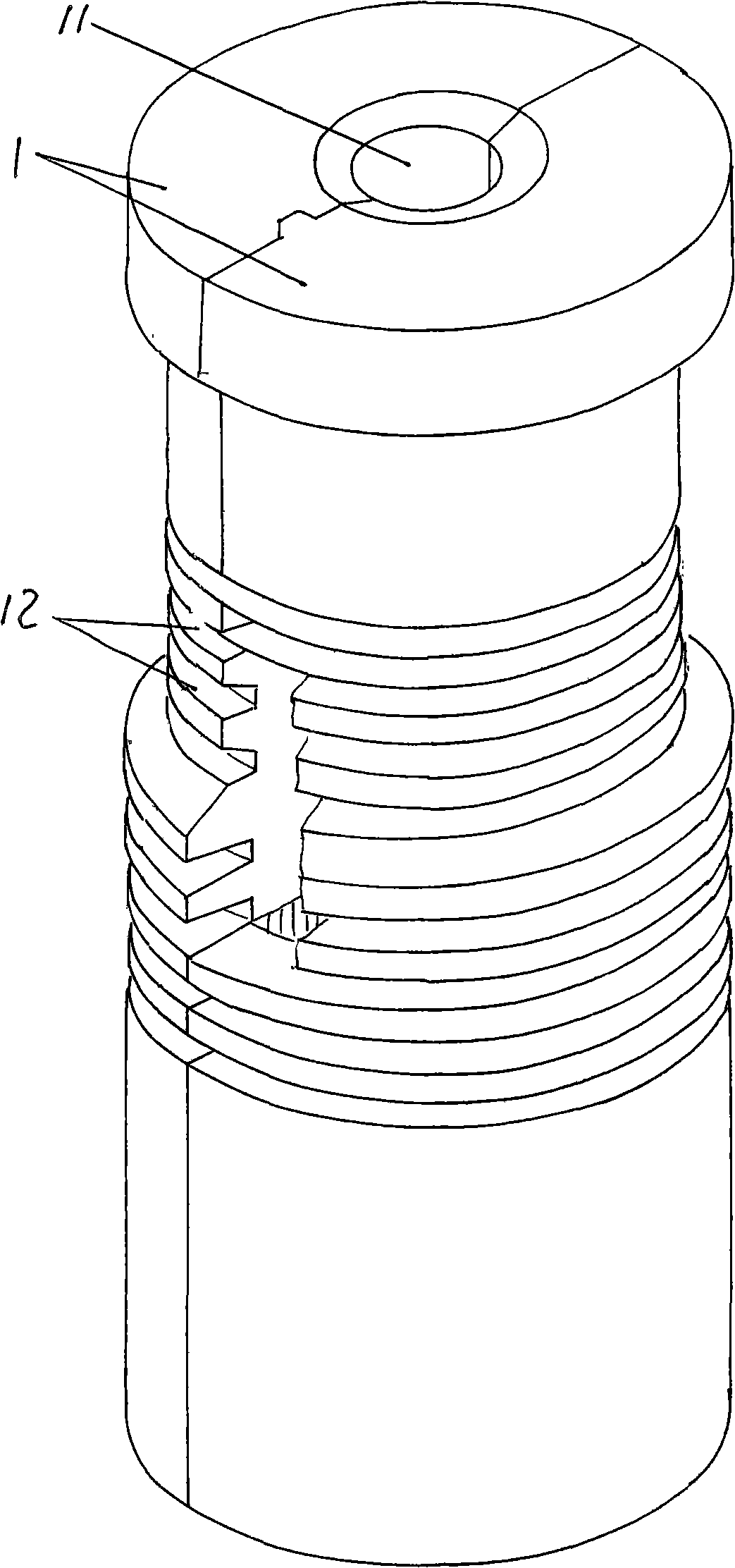

[0010] Please refer to the accompanying drawings, a pair of half-molds 1 is provided, the inner side of each half-mold 1 is processed with a mold cavity 11, and in the state of use, a pair of half-molds 1 are merged face to face. In order to improve the heat dissipation effect of a pair of half molds 1, and not damage the strength of a pair of half molds 1, the preferred solution adopted by the applicant is on the outer walls of a pair of half molds 1, more specifically on a pair of half molds A plurality of heat dissipation grooves 12 are provided at intervals on the outer wall of the middle region in the height direction of 1 , preferably but not limited to, the cross-sectional shape of the heat dissipation grooves 12 is trapezoidal.

[0011] Through the applicant, the mold for processing the glass container with the cooling groove 12 of the present invention and the mold that does not have the cooling groove 12 in the prior art have carried out a comparative test on processi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com