Silencer

A muffler and muffler pipe technology, which is applied in the direction of muffler devices, machines/engines, engine components, etc., can solve problems such as threats to the working life of the muffler, affecting work efficiency and service life, so as to enhance work efficiency and service life, avoid Vibration and damage, the effect of accelerating heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

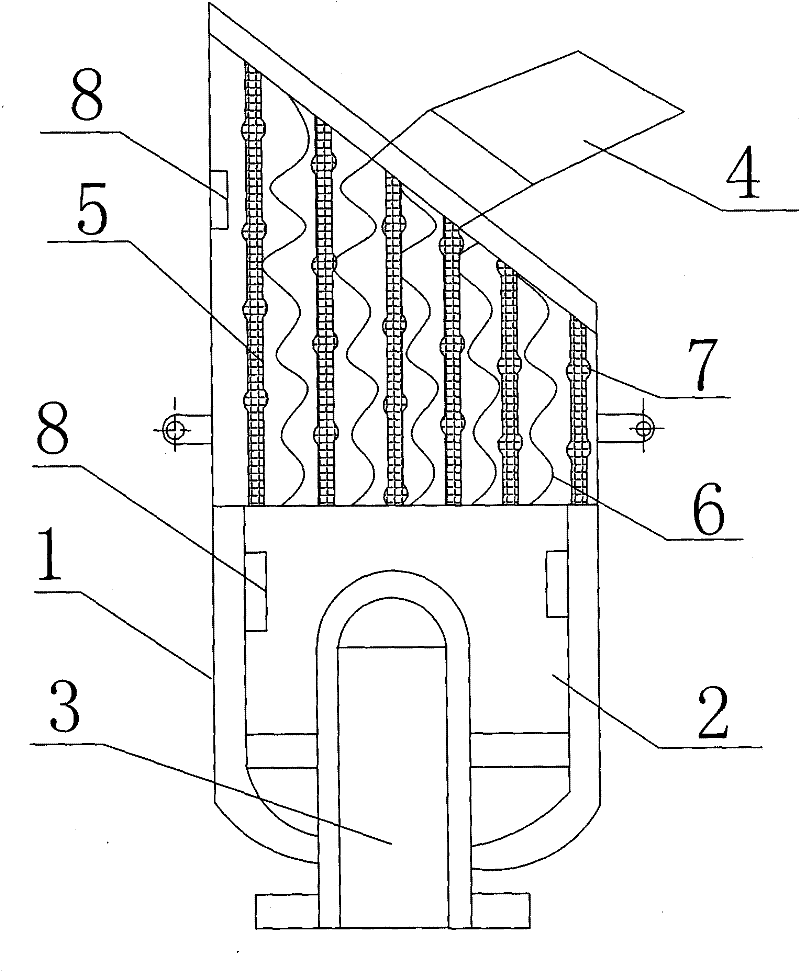

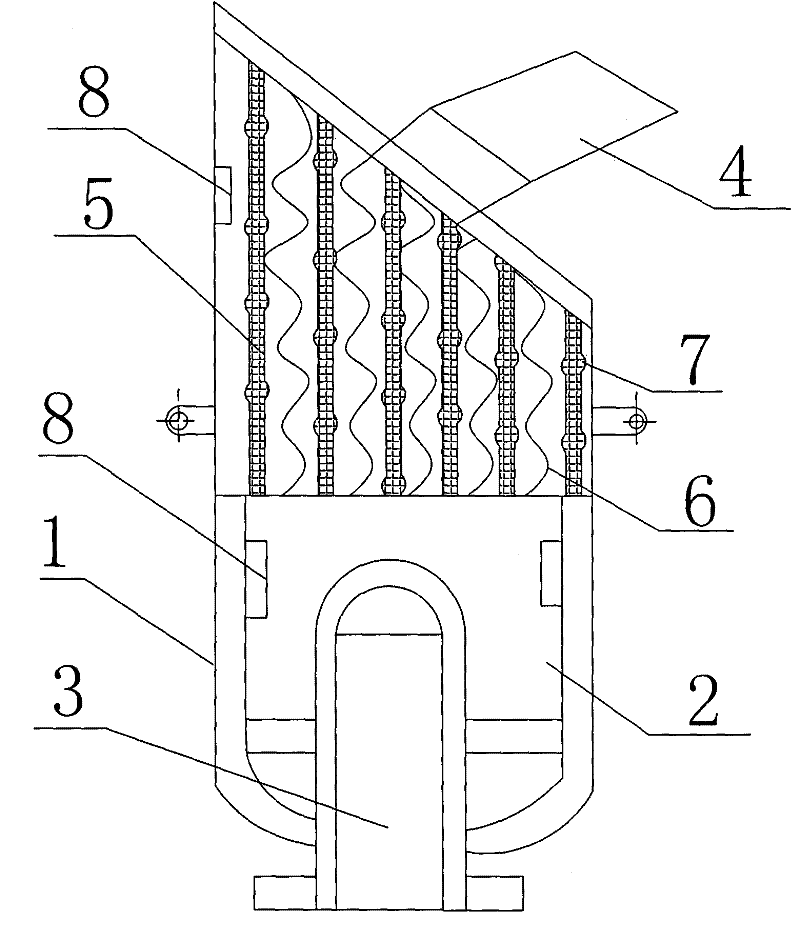

[0009] Such as figure 1 The shown muffler of the present invention comprises a shell 1, an inner core 2, an air intake hole 3 and an exhaust hole 4, the air intake hole 3 and the exhaust hole 4 are arranged on the shell 1, and the inner core 2 is provided with a uniform arrangement The silencer pipe 5 is filled with sound-absorbing glass wool 6, the silencer pipe 5 is provided with cooling holes 6, and the wall of the inner core 2 is provided with three shock pads 8.

[0010] The muffler pipe 5 is provided with cooling holes 6, which can dissipate the heat generated inside the muffler in time, and the inner core wall is provided with shock-absorbing pads 8, which can avoid the vibration and shock caused by the impact of the gas with a relatively large flow rate on the muffler. damage, enhancing its working efficiency and service life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com