Energy conversion module used for laser power supply system

A technology of energy conversion and laser energy supply, which is applied in the direction of photovoltaic modules, photovoltaic power generation, photovoltaic power stations, etc., can solve the problems of low efficiency of laser energy conversion chips, inability to closely cooperate with optical fibers and flanges, and is not conducive to mass production. Laser energy conversion chip and laser coupling accuracy, reduce flange machining or die-casting process requirements, and reduce the effect of expensive equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

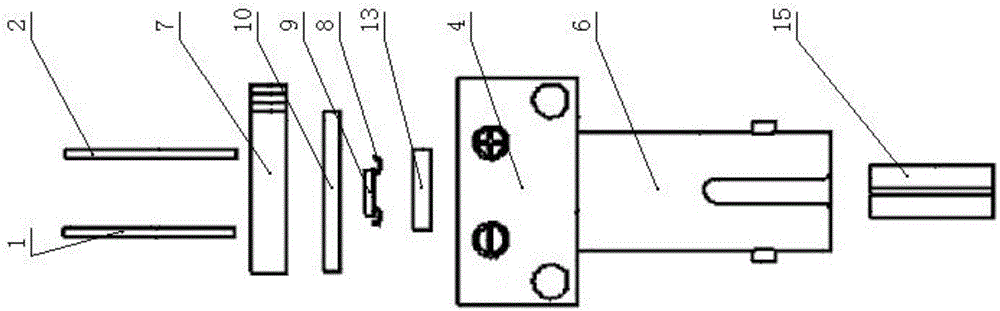

[0024] An energy conversion module for a laser energy supply system, such as Figure 1-7 As shown, the innovation of the present invention lies in: including base 4, optical fiber connector 6, laser energy conversion chip 9 and heat sink 10, described optical fiber connector is installed on the bottom surface of the base, made in the base above the optical fiber connector by label 7 A cavity composed of a number 12, a protective sheet 13 is embedded in the base near the optical fiber connector below the cavity, a heat sink is embedded in the cavity above the protective sheet, and the laser is arranged on the surface of the cooling sheet facing the protective sheet. Energy conversion chip, the two stages of the laser energy conversion chip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com