Maize plant grower processing method, product and produced environment-protective handicraft

A technology for handicrafts and growths, which is applied to wood processing utensils, decorative arts, manufacturing tools, etc., can solve the problems of narrow use of corn plant growths and inability to use handicrafts, etc., and achieves the effects of low cost, simple structure, and storage and transportation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

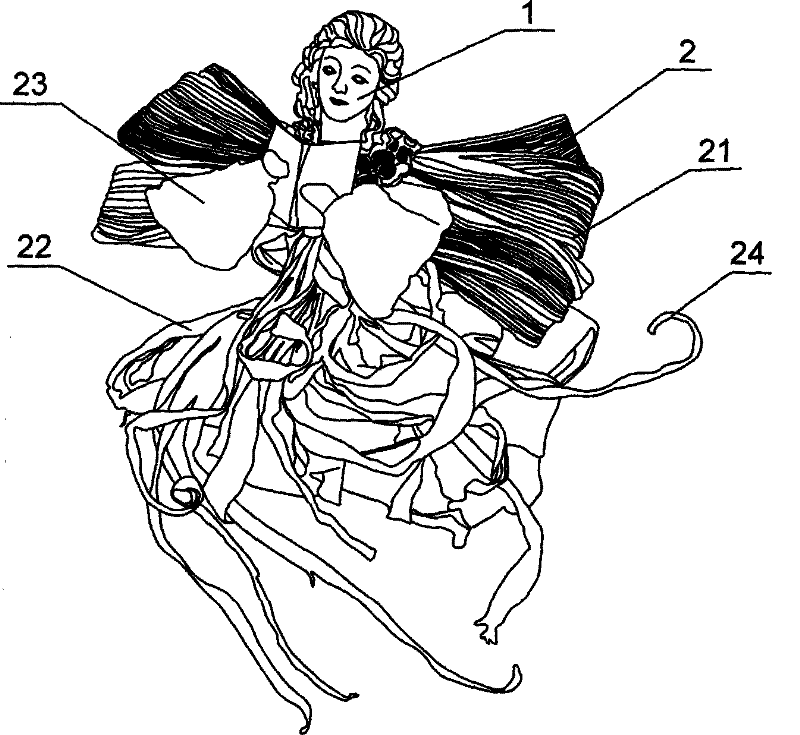

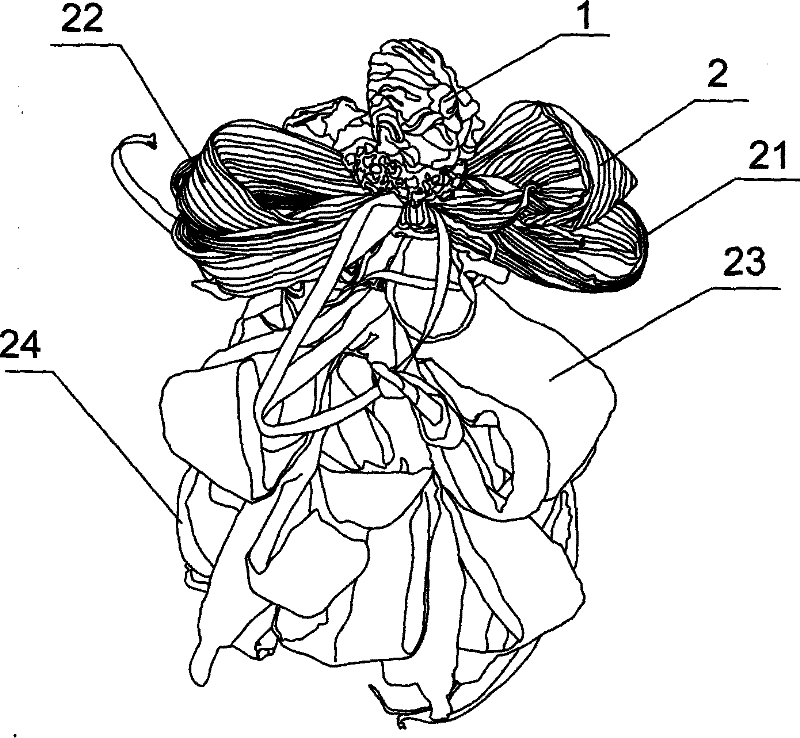

Embodiment 1

[0050] Embodiment 1: a kind of natural corn plant growth thing processing method, it comprises the steps:

[0051] (1) Washing and sterilization: After picking the corn plant growths, select the ones with good appearance to clean them, add disinfectants to the cleaning solution to disinfect them, and dry them;

[0052] (2) Dyeing and finishing: arrange them into consistent bundles or bundles, and immerse them in a solution containing coloring agents to make them fully dyed;

[0053] (3) drying: after it is drained, it is dried for subsequent use;

[0054] (4) Trimming or winding: trimming, or winding, tearing, bending, combing to the desired shape;

[0055] (5) Anti-corrosion treatment: submerge it in paint or other anti-corrosion liquids, take it out and dry it to obtain the finished product;

[0056] (6) Processing and assembly: combine the product with other items, components or devices to make environmentally friendly handicrafts.

[0057]The aforementioned corn plant g...

Embodiment 2

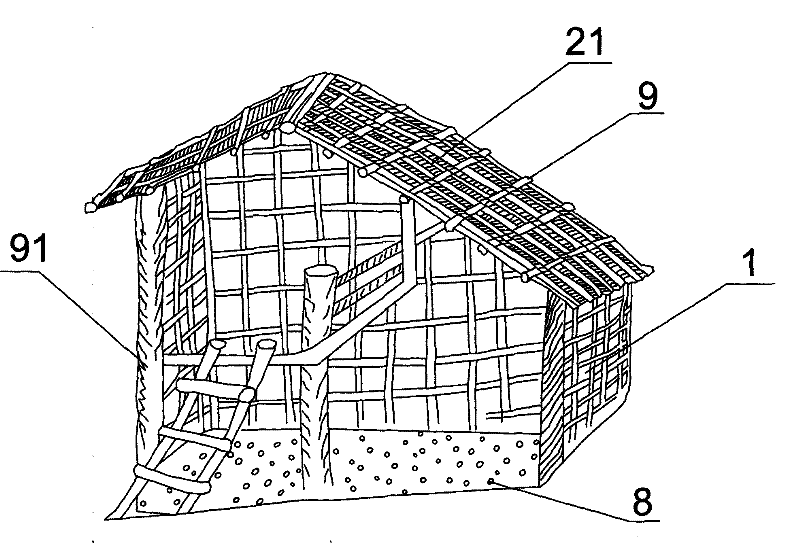

[0060] Example 2: see image 3 , The corn plant growth processing method and products used in the present embodiment are the same as in Embodiment 1, except that the environmental protection handicraft that adopts the aforementioned products constructed by it is a manger. Its basic structure is the same as that of Embodiment 1, the difference is that the hard molding body 1 is used to support and form a plastic molded house and accessories of a part of the handicraft, the body 1 is composed of a roof slope and four A combination of two elongated walls, the outer surface of the roof is pasted and covered with a layer of corn leaves or corn wrappers 21; 9; what the four corners of its metope adopt is thicker corn stalk 91, and its front part is provided with some spices 8, what adopted in the present embodiment is cinnamon slice or chip.

Embodiment 3

[0061] Embodiment 3: see Figure 4 , the corn plant growth processing method and products used in this embodiment are the same as in Example 1, the difference is that the environmental protection handicraft using the aforementioned products is constructed, and an environmental protection handicraft using the aforementioned products is constructed. It is a handicraft flower socket, which includes a branch body 1, and three flower leaves 2 arranged on the body 1, flowers 4 connected to the body through a flower stalk 3, among the flower leaves 2, three of them are All are corn leaves trimmed into strip-shaped leaves and dried; the flowers 4 are composed of strip-shaped corn wrapping leaves that have been sterilized, dyed, dried, and wound; the flowers and leaves 2 are composed of Corn leaves, or the corn wrappers that make up the flowers 4, are also provided with an anti-corrosion coating on their surfaces and are colored; wherein the corn leaves 2 are colored green, and the cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com