Method for processing complex surface knife tool

A processing method and technology for complex profiles, which are applied in metal processing equipment, manufacturing tools, grinding machine parts, etc., can solve the problems of low cost, high dressing efficiency, and can not take into account the dressing efficiency and cost. High trimming efficiency and error-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

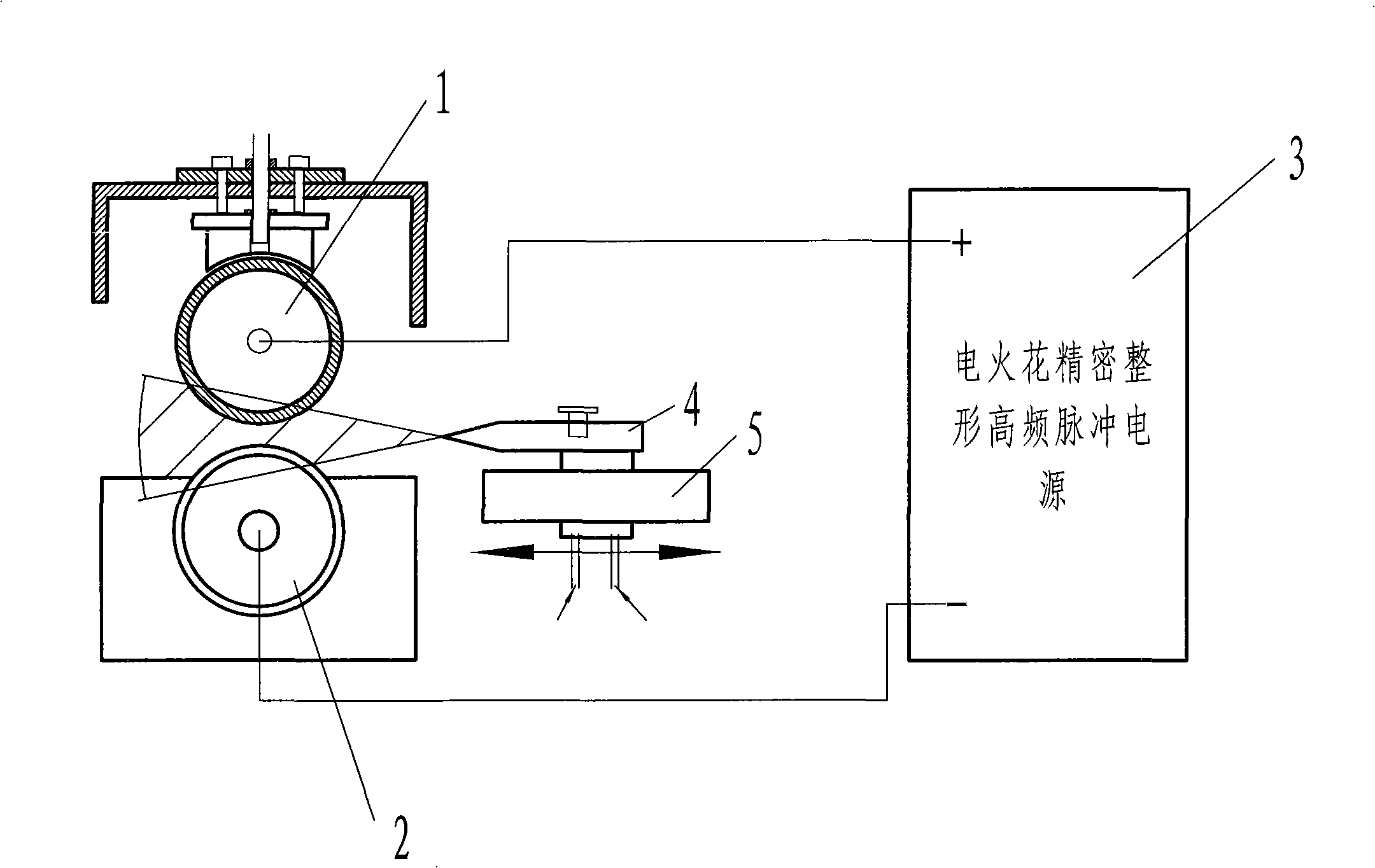

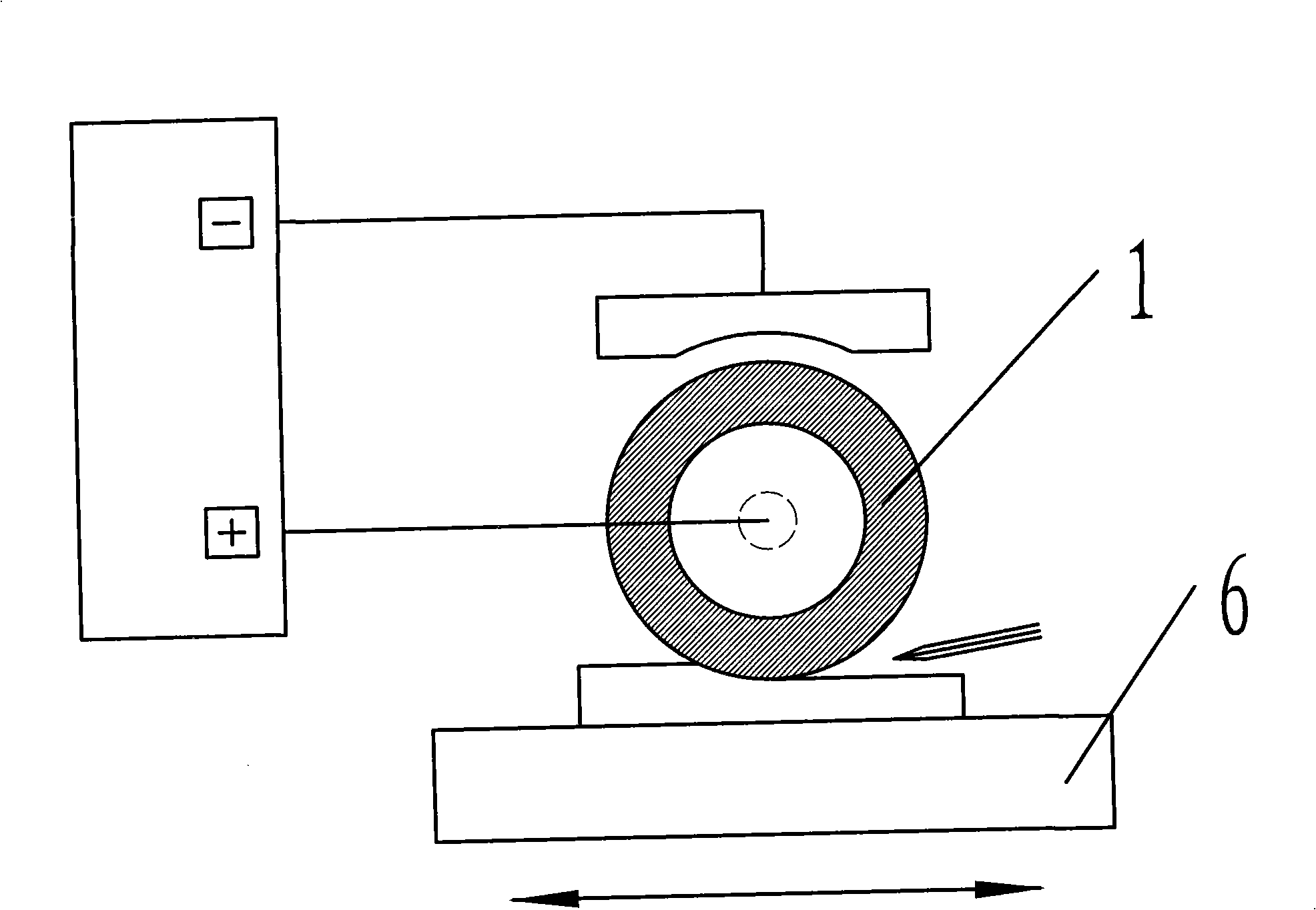

[0042] The present invention will be further described below in conjunction with the accompanying drawings.

[0043] refer to Figure 1 ~ Figure 3 , a kind of processing method of complicated surface cutting tool, described processing method comprises the following steps:

[0044] (1) According to the structure and size requirements of the tool to be processed, the tool electrode is designed according to the tool design theory and the processing principle of the profiling method;

[0045] (2) Use the tool electrode to trim the profile of the grinding wheel, including:

[0046](2.1), the metal bond diamond grinding wheel is connected to the positive pole of the high-frequency pulse power supply through the anode fixing device as the anode, and the tool electrode is connected to the negative pole of the high-frequency pulse power supply as the cathode;

[0047] (2.2), between the metal-bonded diamond grinding wheel and the tool electrode, a medium with conducting poles and coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com