Safety glass protection screen for LCD, LCD using the same

A technology of liquid crystal display and safety glass, applied in instruments, optics, nonlinear optics, etc., can solve the problems of reducing the surface reflectivity, prone to rainbows on the surface, and difficult to control the film thickness, so as to improve safety and improve image clarity. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

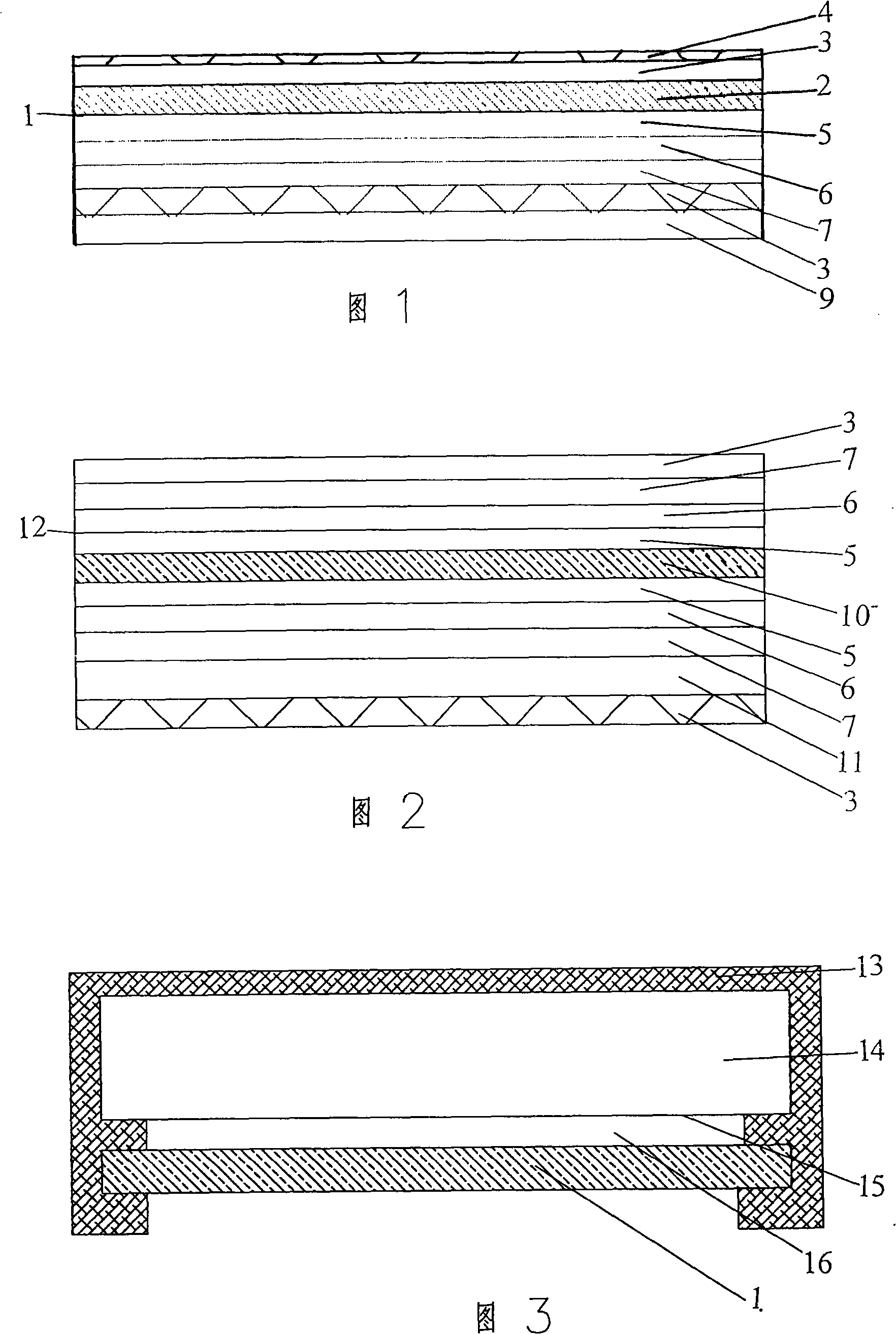

[0019] Fig. 1 has provided present embodiment 1 figure. Referring to FIG. 1 , a safety glass protective screen 1 with high light transmittance adopts 3 mm thick tempered glass as the glass substrate 2 . On one side of the glass substrate 2, a thin film 3 of anti-reflection and anti-reflection film system is coated with a vacuum magnetron sputtering method, and the thin film 3 is sequentially made of TiO from the substrate to the outside. 2 / SiO 2 / TiO 2 / SiO 2 composition, its thickness ranges from TiO 2 5-18nm, SiO 2 20-50nm, TiO 2 20-50nm, SiO 2 It is 70-140nm, and the coating 4 that prevents dirt from adhering is sprayed on the outermost surface. The coating 4 is a commercially available organic silicone oil commodity. The glue 5 is compounded with a polyester film (BOPET) 6 with a thickness of 125 μm on the glass substrate 2, and a hardened light-cured acrylate film layer 7 is coated on its surface, with a thickness of 12 μm, so that its surface hardness is greater ...

Embodiment 2

[0021] Figure 2 shows the structure diagram of Embodiment 2. Referring to Fig. 2, the safety glass protective screen 12 with high light transmittance adopts 3 mm thick glass without tempering treatment as the glass substrate 10, and there is an acrylic pressure-sensitive adhesive 5 on one side of the glass substrate 10, through which the pressure-sensitive adhesive 5 On the glass substrate 10, a polyester film (BOPET) 6 with a thickness of 125 μm is compounded, and the surface of the polyester film (BOPET) 6 is coated with a hardened light-cured acrylate film layer 7, with a thickness of 12 μm, so that the surface hardness is greater than 2H, using the vacuum magnetron sputtering method to coat the thin film 3 of the anti-reflection and anti-reflection film system on the 7 sides, and the acrylate pressure-sensitive adhesive 5 on the other side of the glass substrate 10, through the pressure Sensitive adhesive 5 is also compounded with polyester film (BOPET) 6 with a thickness ...

Embodiment 3

[0023] Fig. 3 has provided present embodiment 3 figure, and Fig. 3 is the structure schematic diagram of liquid crystal display of the present invention, and liquid crystal display is by the safety glass protection screen 1 of embodiment 1 (or 2) high light transmittance by display housing 13, display 14, structure (or 12) composition, there is 5mm safety dimension 16 therebetween when protective screen 1 and display screen 15 are installed, during installation, plastic film surface 6 (coated with one deck semiconductor film 9 or 11 on it) faces display, because double Surface reflectance superposition is less than 1.5%, basically no ghosting. The protection screen of the present invention replaces the PET protective film with only about 90% light transmittance on the display panel in the past, and the total light transmittance is increased by 6%, so that the LCD TV image is brighter and clearer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com