Scroll fluid machine

A fluid machinery and scroll technology, applied in the direction of rotary piston machinery, rotary piston engines, mechanical equipment, etc., can solve the problems of complex processing procedures, poor compression efficiency, long processing time, etc., to shorten processing time and improve Compression efficiency, simple shape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 5 approach

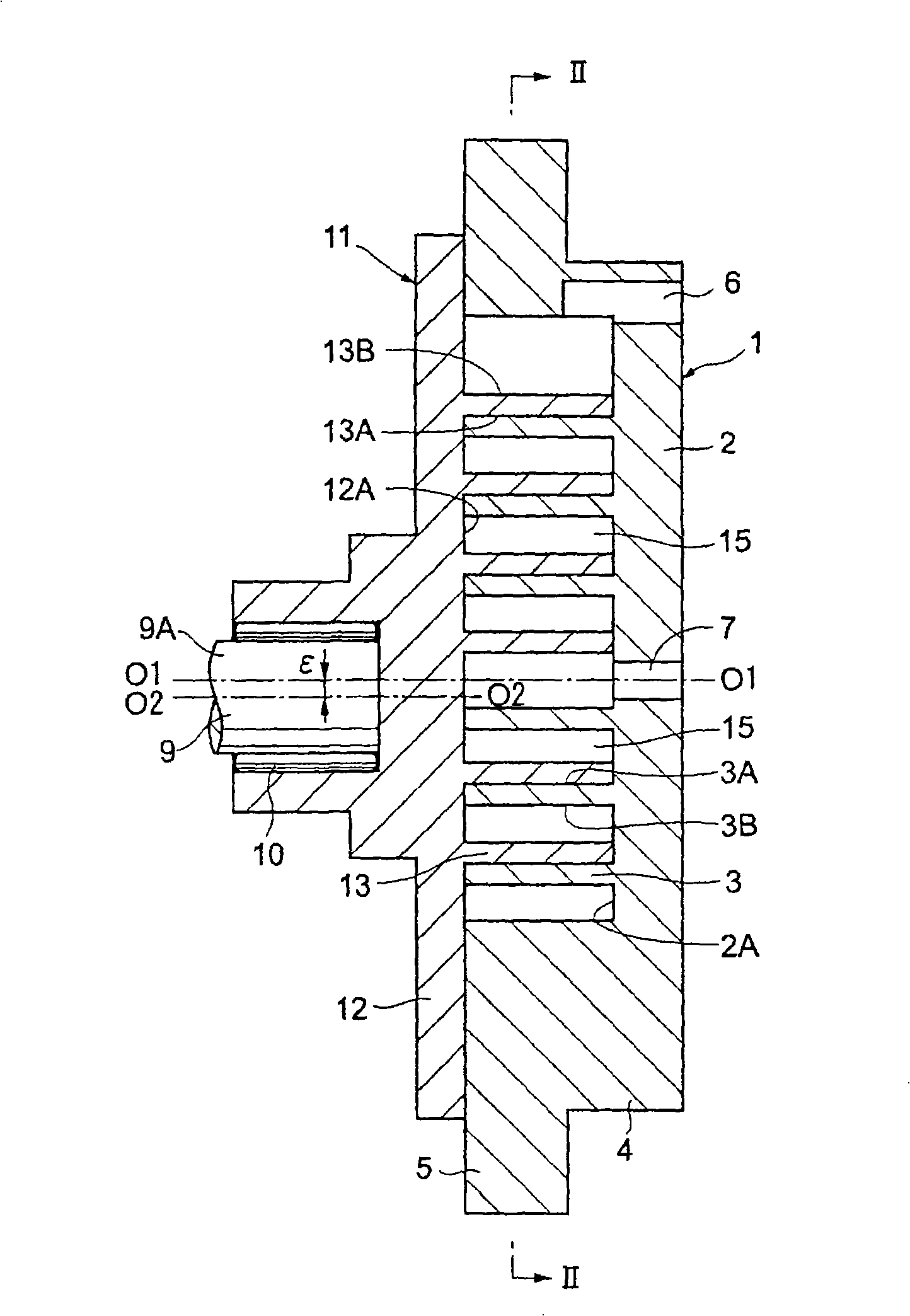

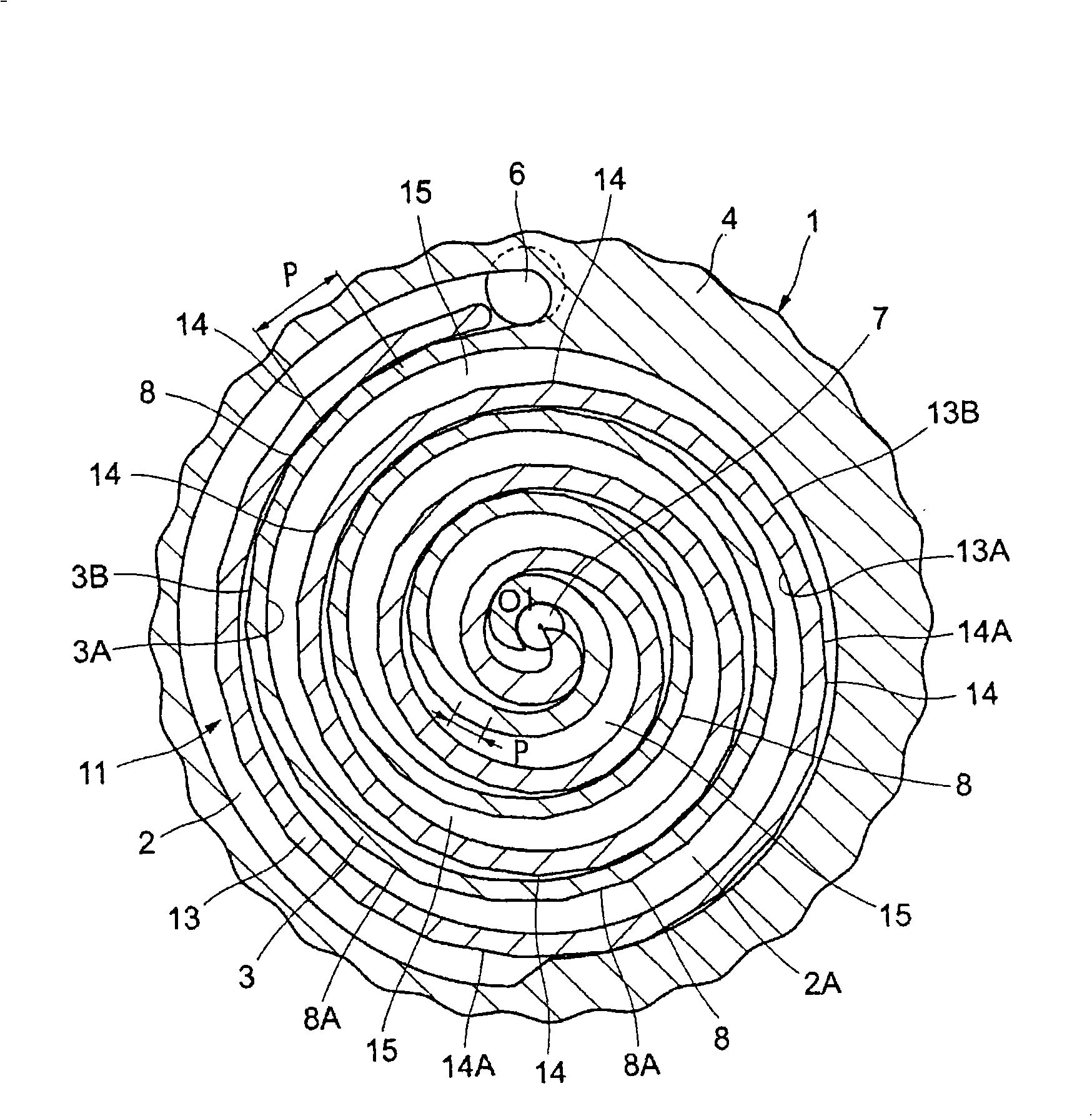

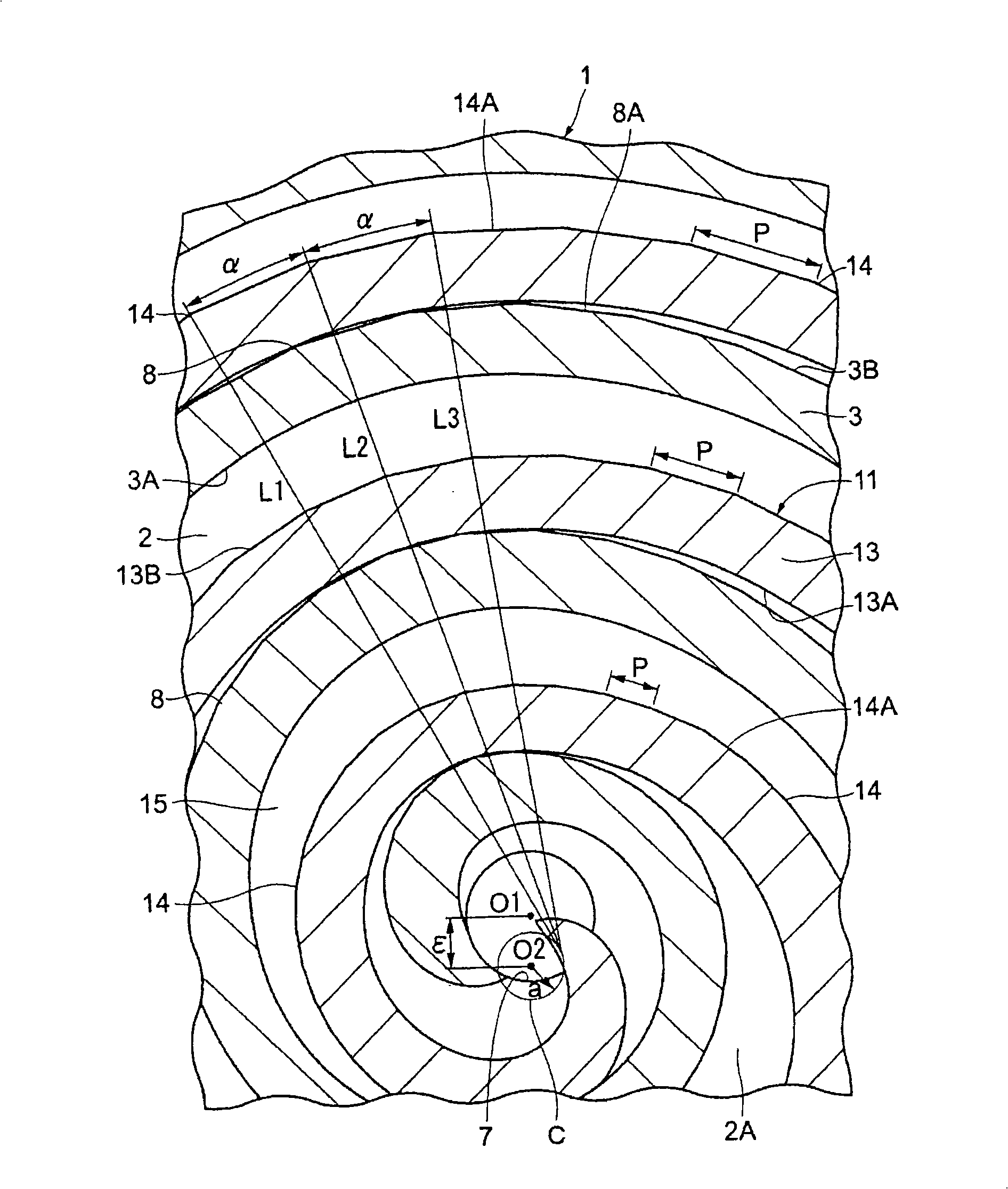

[0142] Next, FIG. 15 shows a fifth embodiment of the present invention, and this embodiment is characterized in that an involute curved portion following the involute is provided on the outer diameter side of the overlapping portion. In addition, in this embodiment, the same code|symbol is attached|subjected to the component element as said 1st Embodiment, and the description is abbreviate|omitted.

[0143] Reference numeral 61 denotes a fixed scroll of a scroll air compressor, and the fixed scroll 61 is composed of an end plate 62, an overlapping portion 63, a cylindrical portion 64, a flange portion (not shown) and the like in substantially the same manner as in the first embodiment. constitute. Furthermore, the overlapping portion 63 is formed in a spiral shape having an inner peripheral surface 63A and an outer peripheral surface 63B.

[0144] However, on the outer peripheral surface 63B of the overlapping portion 63, a plurality of closest portions 65 and a flat surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com