Rolled steel with excellent toughness of sparkling heat effect section and manufacturing method thereof

A technology of welding heat effect and manufacturing method, applied in the field of steel, to achieve the effect of suppressing the fluctuation of toughness and preventing the deterioration of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] After primary refining of molten iron in a 240-ton converter, steel is tapped from the converter to ladles, and secondary refining is performed while adjusting the composition and temperature.

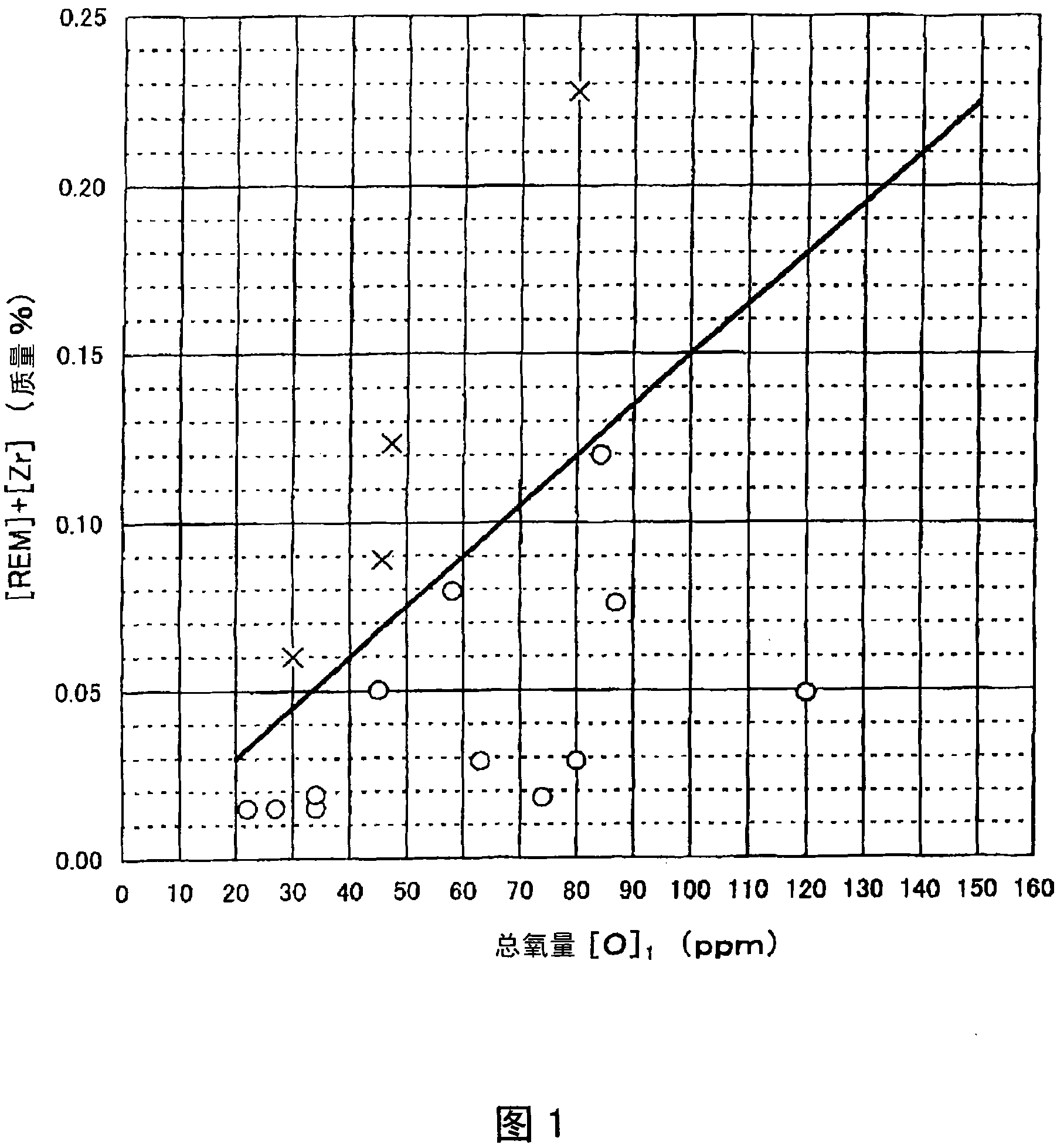

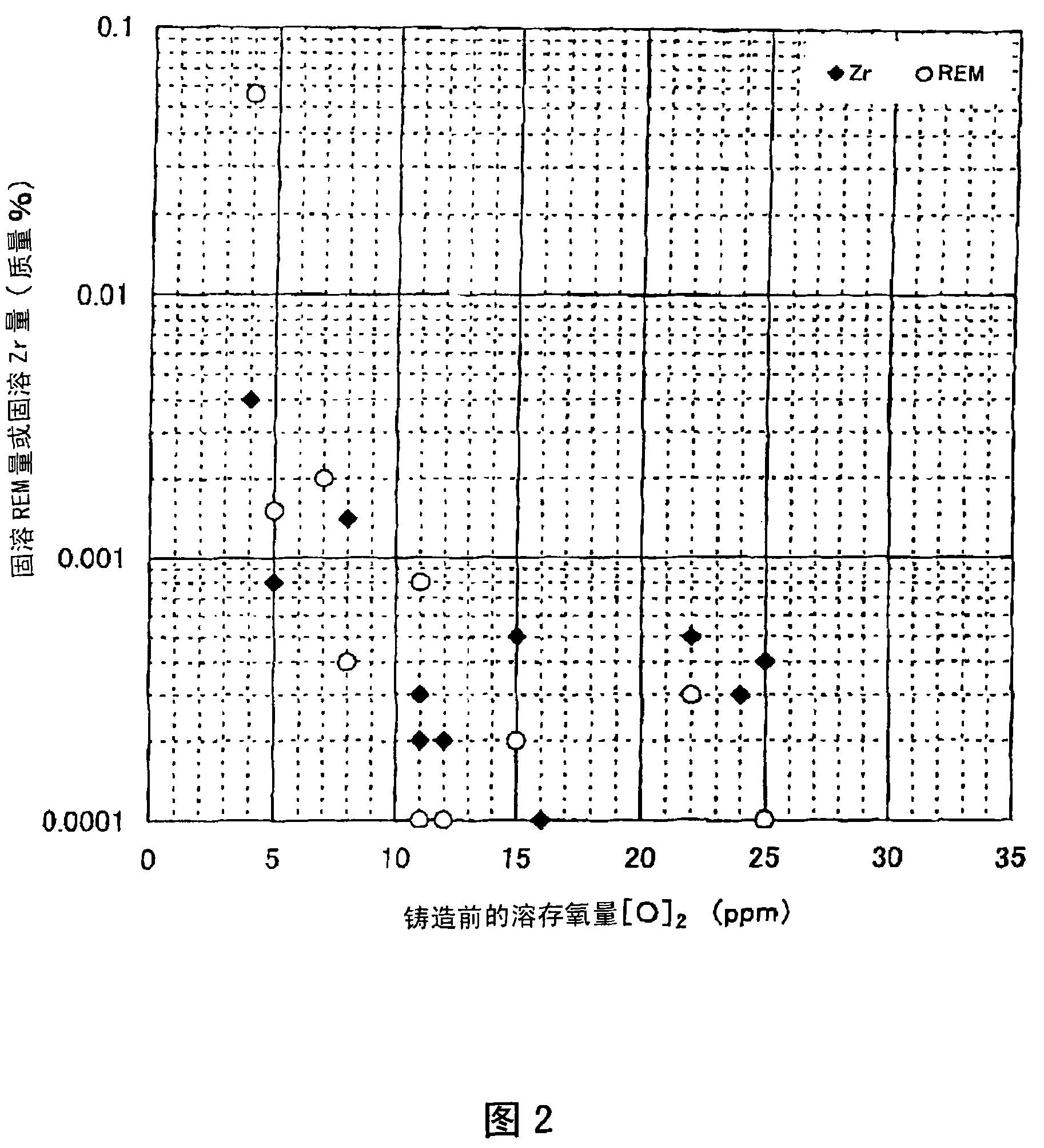

[0078] In the ladle, according to the deoxidation method shown in the following table 1, adjust to the total oxygen amount [O] shown in the following table 1 1 , while adjusting the chemical composition. Total oxygen [O] 1 This means that the amount of oxygen contained as dissolved atoms in molten steel and the amount of oxygen present as oxide-based inclusions combined together, and the amount of oxygen contained as dissolved atoms in molten steel, use a solid electrolyte The oxygen sensor is used for measurement, and the total oxygen content is measured by general inert gas melting-infrared absorption method. Also, in Table 1 below, except for the total oxygen amount [O] 1 In addition, the amount of dissolved oxygen in the molten steel before adding REM and Zr is also shown...

experiment example 2

[0112] The steel slabs of No. 3, No. 4, No. 8, No. 14, and No. 20 obtained in Experimental Example 1 above were hot-rolled to obtain steel plates with a thickness of 30 mm.

[0113] For a section perpendicular to the rolling direction of the obtained steel sheet, the composition of the inclusions was quantitatively analyzed under the same conditions as in Experimental Example 1 above, and the moles of each element contained in the inclusions to be analyzed were calculated. ratio. The observation position is D / 4 of the steel plate (where D is the thickness of the steel plate), and the observation conditions are except that the observation field area is 1cm 2 Other than that, the conditions are the same as those of the above-mentioned experimental examples. The calculation results of the molar ratio are shown in Table 5 below. Blank columns in Table 5 below indicate that they were not detected.

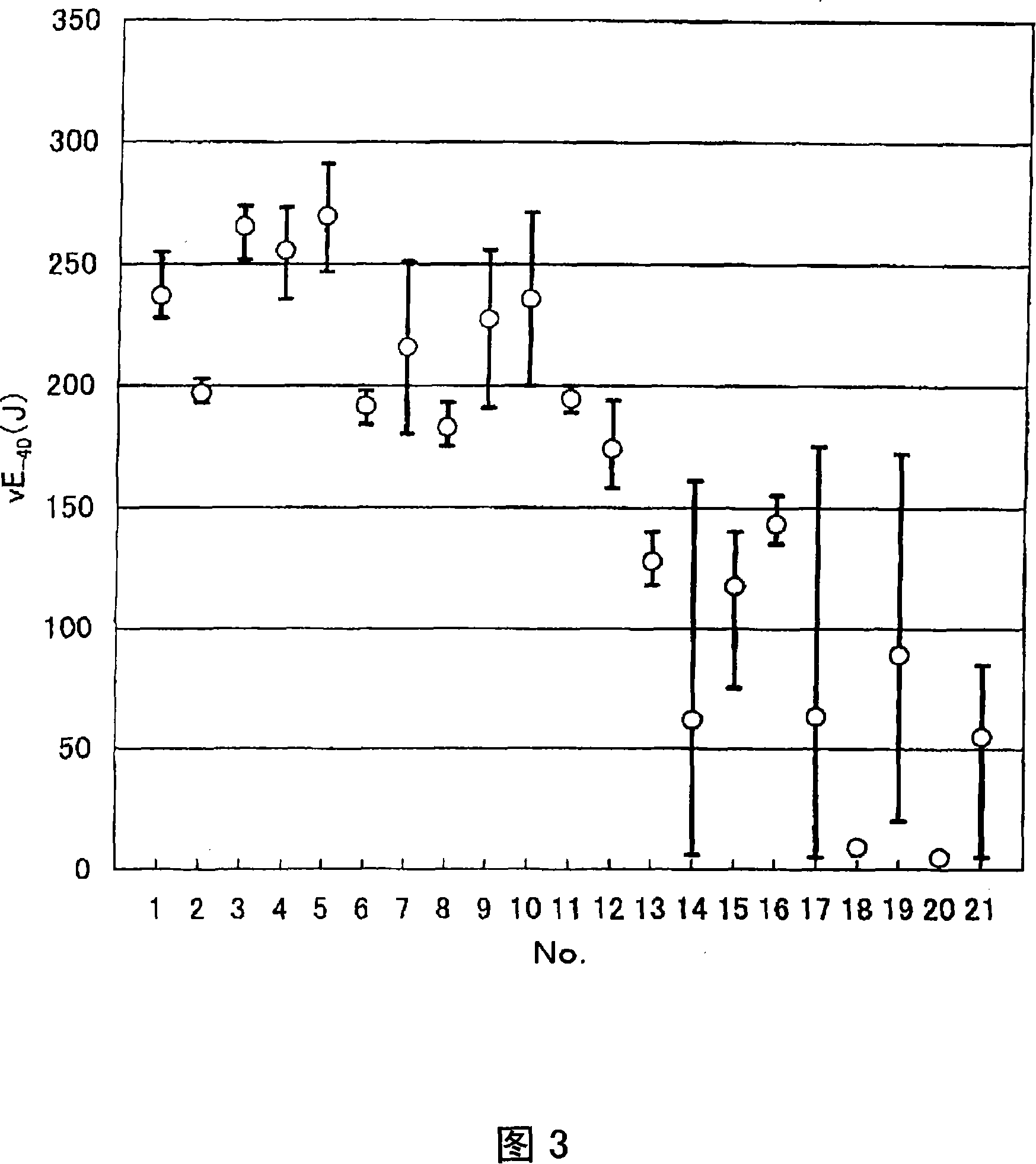

[0114] Next, in order to evaluate the toughness of the HAZ affected by heat duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com