Combined stream pulling type diving buoyancy lift equipment and technique for removing nature aquifer blue algae

A push-flow, equipment technology, applied in flotation water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of ecological restoration treatment of unused water bodies, pollution, and large land occupation, and improve practicability. and application range, restore the natural environment, and reduce the effect of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Process a river course connected to a lake polluted by blue-green algae. The original river course is 2 meters wide and 1 meter deep. Build the push-flow type diving buoyancy equipment of the present invention on the river course, widen the river course and dig deep to form a buoyant pool body, long: Width: depth is 4:4:4.4m. A submersible pump (80m 3 / h) and a pipe with a diameter of 10cm, a baffle is set 0.3m behind the front baffle, and the lower end of the baffle is 10-30cm away from the bottom of the pool. An air diffusion distributor is set at the bottom to distribute the dissolved gas water that has been added, and the porous tube is placed 0.05m away from the water bottom under the baffle to add chemicals and gas to the incoming sewage. The reflux water is 40 cubic meters per hour, which is extracted in the clear water pool by the dissolved air pump, and the dosage is 2g / min of polyaluminum and 0.1g / min of polyacrylamide. A middle partition is set 1m behind th...

Embodiment 2

[0059] Set up a 10m long wave catchment tank in the water beside the embankment (see Figure 11 , Figure 12 ), the edge height of the front edge of the groove is 30cm, and the edge height of the rear end is 50cm. Set up a 1m-long 45°C slope, one side is connected to the front end of the fishing tank and the other is fixed underwater. The two ends of the tank are closed, and after the sewage is concentrated, the three 20cm pipes in the middle enter the whole submerged buoyancy device made of steel frame PVC plastic board on the other side of the embankment. The buoyancy equipment enters 2m of water 3 / min. At the same time, meter solid aluminum sulfate into the sump, 30g / min. The equipment is 4m long, 4m wide, and 5m long. The difference from Example 1 is that there is a 0.6m clear water pool behind the outlet, and the dissolved air pump pumps 40m of water from the clear water pool per hour. 3 , the dissolved gas water and the three water inlet pipes flow into the equipme...

Embodiment 3

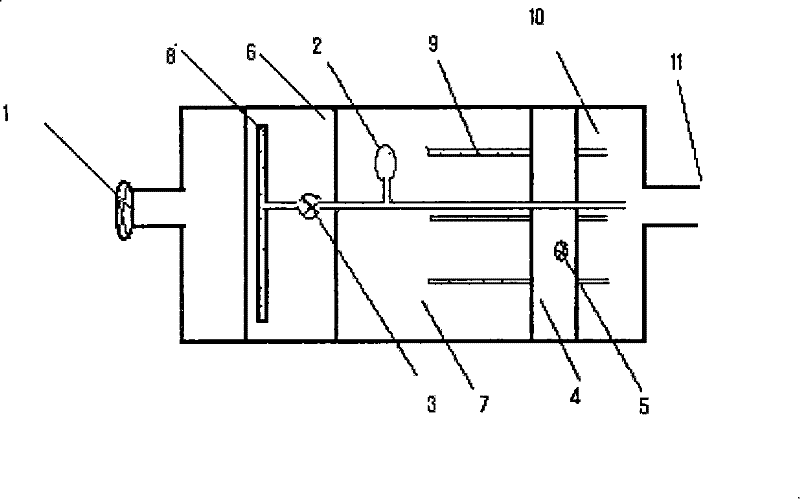

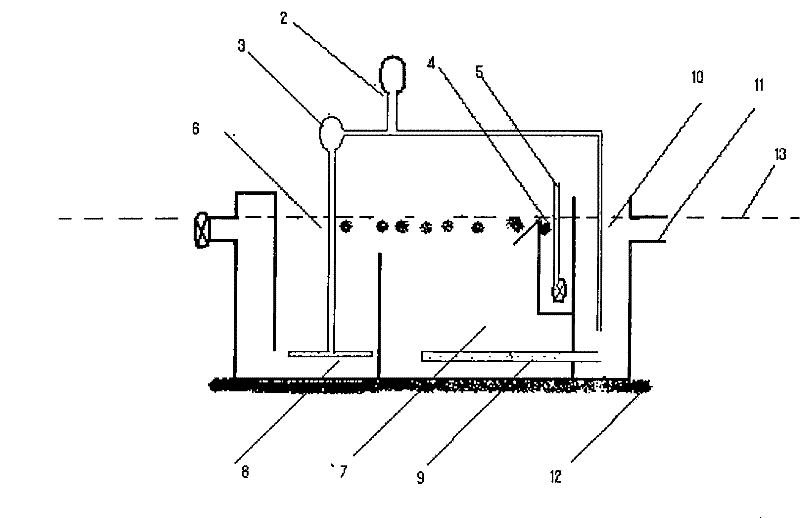

[0061] Diving in the water with a glass-steel sealed push-flow diving buoyancy pool (see Figure 7 , Figure 8 ), surrounding the lake water with soft bamboo (see Figure 15 ), the sewage is transported to the pool body in a horizontal push-flow manner with a water pump, and the water inflow is 400m 3 / h, the dosing nozzle is connected to the return pipe, the average horizontal flow rate is 5mm / s, the flocculation time is 10min, the flow rate in the flocculation tank is 10mm / s, the air flotation is 2.5mm / s, the time is 23min, and the maximum reflux water is 10%. The volume of the pressure dissolved air tank is calculated as a packed tower with a diameter of 0.5m and a height of 3m based on the minimum reflux water flow for 1min. Maximum air consumption 0.45m 3 / min. Air pump pressure 6kg / cm 2 . The pressure dissolved air releaser adopts TS78-releaser. The return water volume is set to 40m per hour 3 , parallel to the water inlet pipe, the pool body is 11m long, 4m wide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com