Polyaniline solid phase micro- extraction head and method for making same

A technology of solid-phase microextraction head and polyaniline, which is applied in the direction of chemical instruments and methods, preparation of test samples, and other chemical processes, can solve the problems of short service life and high price of solid-phase microextraction head, and achieve mechanical The effect of superior strength, low price, and good physical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The stainless steel wire (diameter 0.35mm, length 75mm) was ground to 0.1mm at the front end 1cm, and this was used as the working electrode, the platinum sheet was used as the counter electrode, and the saturated calomel electrode was used as the reference electrode. Put it into a water-acetonitrile (V:V=49:1) solution containing 0.2M aniline and 0.5M trifluoroacetic acid, within the range of -0.2 to 1.2V, 25mVs -1 Cycle a certain number of times until the power is 1C, and keep it at 1.2V for 5s. Immerse in methanol for 100s, wash with deionized water for 10s, repeat twice. Vacuum-dried at 80°C for 5 hours, cross-linked at 125°C for 5 hours, and baked and aged at high temperature (280°C) for 2 hours in a gas chromatography inlet to make polyaniline solid-phase microextraction tips (fibers).

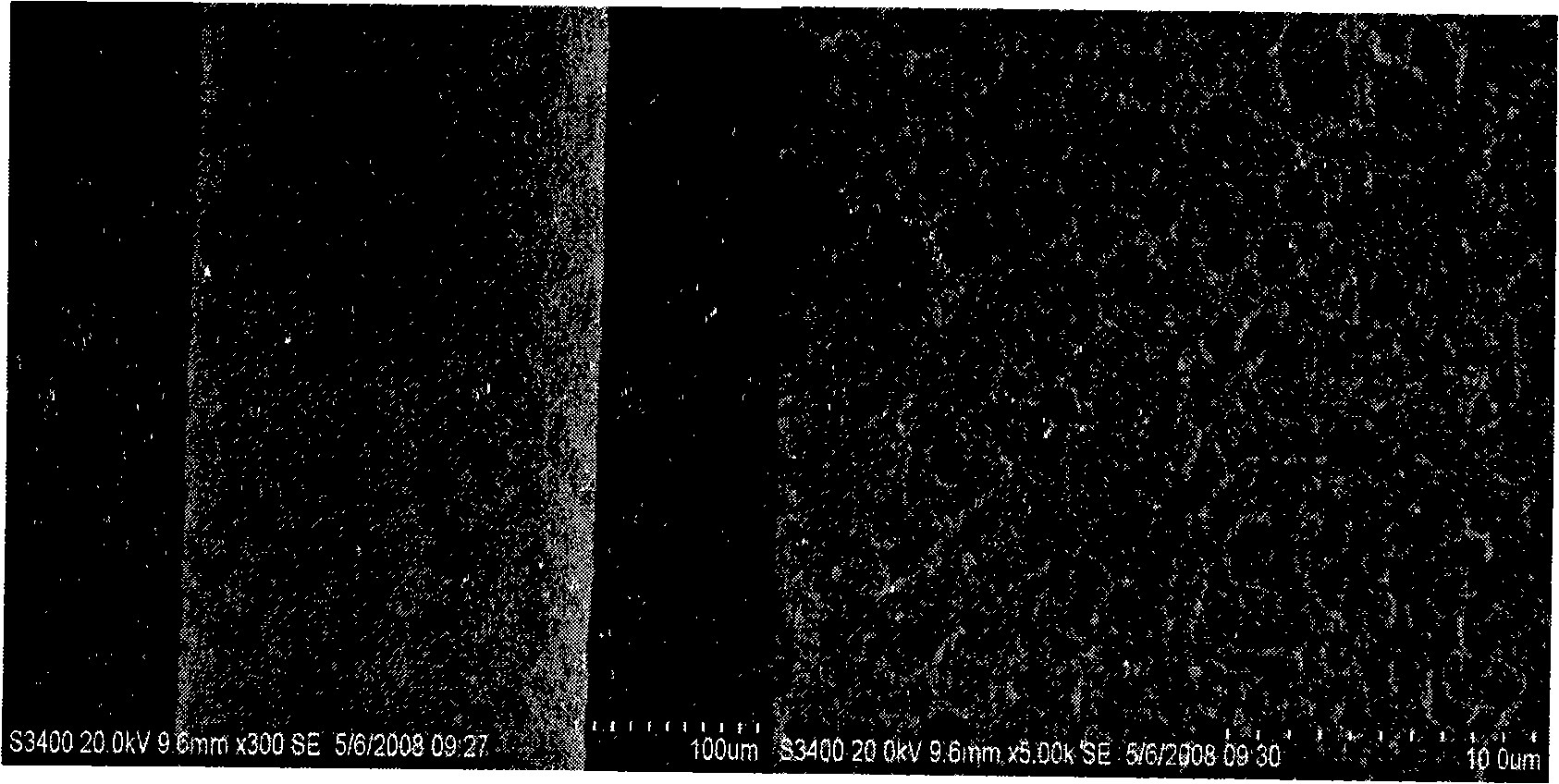

[0022] figure 1 : SEM of a polyaniline solid-phase microextraction head (left: 300X, right: 5000X). The scanning electron microscope atlas shows that the extraction head is uni...

Embodiment 2

[0028] The stainless steel wire (0.35 mm in diameter, 75 mm in length) was ground to a diameter of 0.12 mm at the front end 1 cm, and this was used as the working electrode, the platinum sheet was used as the counter electrode, and the saturated calomel electrode was used as the reference electrode. Put it into the trifluoroacetic acid solution containing 0.2M aniline, in the range of -0.2 ~ 1.2V, 25mV s -1 Cycle a certain number of times until the power is 1C, and keep it at 1.2V for 5s. Immerse in ethanol for 300s, wash in deionized water for 10s, repeat twice. Vacuum-dried at 80°C for 5 hours, cross-linked at 150°C for 2 hours, and then baked and aged at high temperature (200°C) for 2 hours in a gas chromatography inlet to make a polyaniline solid-phase microextraction tip (fiber).

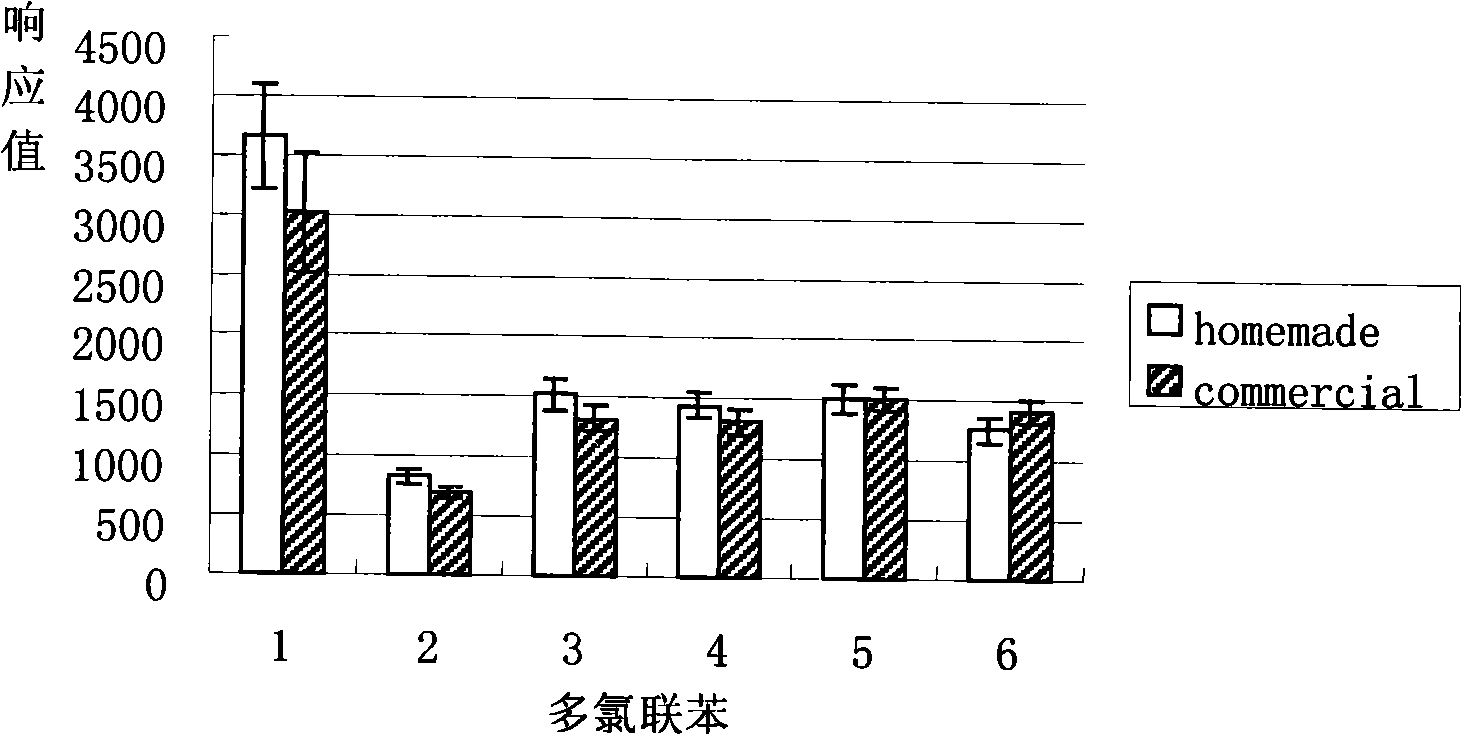

[0029] figure 2 Comparison of the optimized extraction efficiency of polyaniline solid-phase microextraction head (fiber) for 6 kinds of polychlorinated biphenyls (concentration is 6.66ppt),...

Embodiment 3

[0038] The stainless steel wire (0.35mm in diameter, 75mm in length) was ground to a diameter of 0.11mm at the front end 1.5cm, and this was used as the working electrode, the platinum sheet was used as the counter electrode, and the saturated calomel electrode was used as the reference electrode. Put it in a water-acetonitrile (V:V=20:1) solution containing 0.2M aniline and 0.5M trifluoroacetic acid, within the range of -0.2 to 1.2V, 20mV s -1 Cycle a certain number of times until the power is 1C, and keep it at 1.2V for 5s. Immerse in dichloromethane for 60s, wash with deionized water for 10s, repeat twice. Vacuum-dried at 80°C for 5 hours, cross-linked at 130°C for 3 hours, and then baked and aged at high temperature (250°C) for 3 hours in a gas chromatography inlet to make a polyaniline solid-phase microextraction tip (fiber).

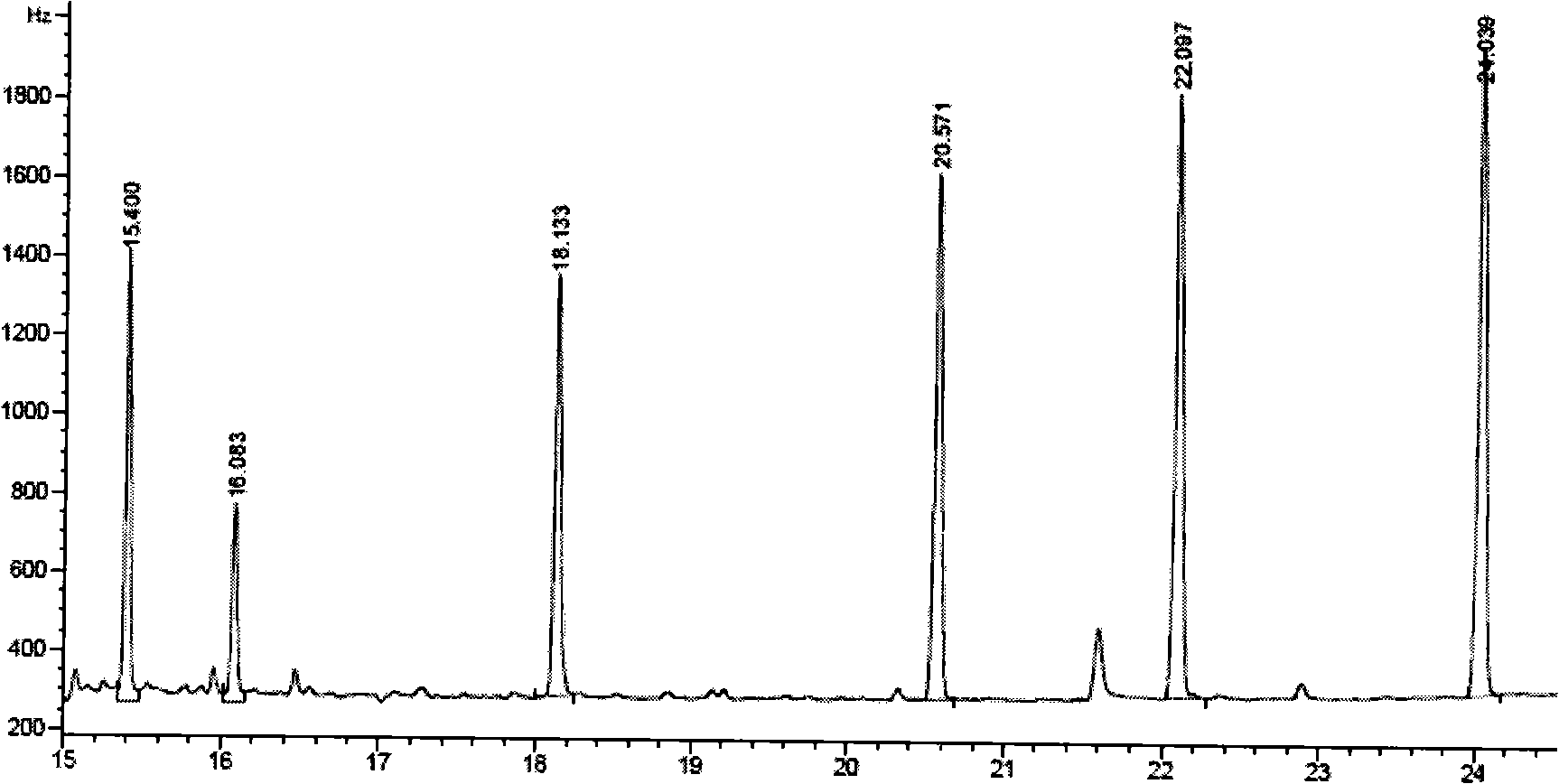

[0039] Extraction of 10 kinds of normal alkanes, phenanthrene, pyrene and dibutyl phthalate.

[0040] GC / FID operating conditions:

[0041] Pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com