Process and device for abstracting lignose with zero discharge of paper making black liquor

A papermaking black liquor, zero-discharge technology, applied in papermaking, cleaning heat transfer devices, textiles and papermaking, etc., can solve the problems of low investment and low cost, and achieve the effect of less investment in equipment, low cost and solving black liquor pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

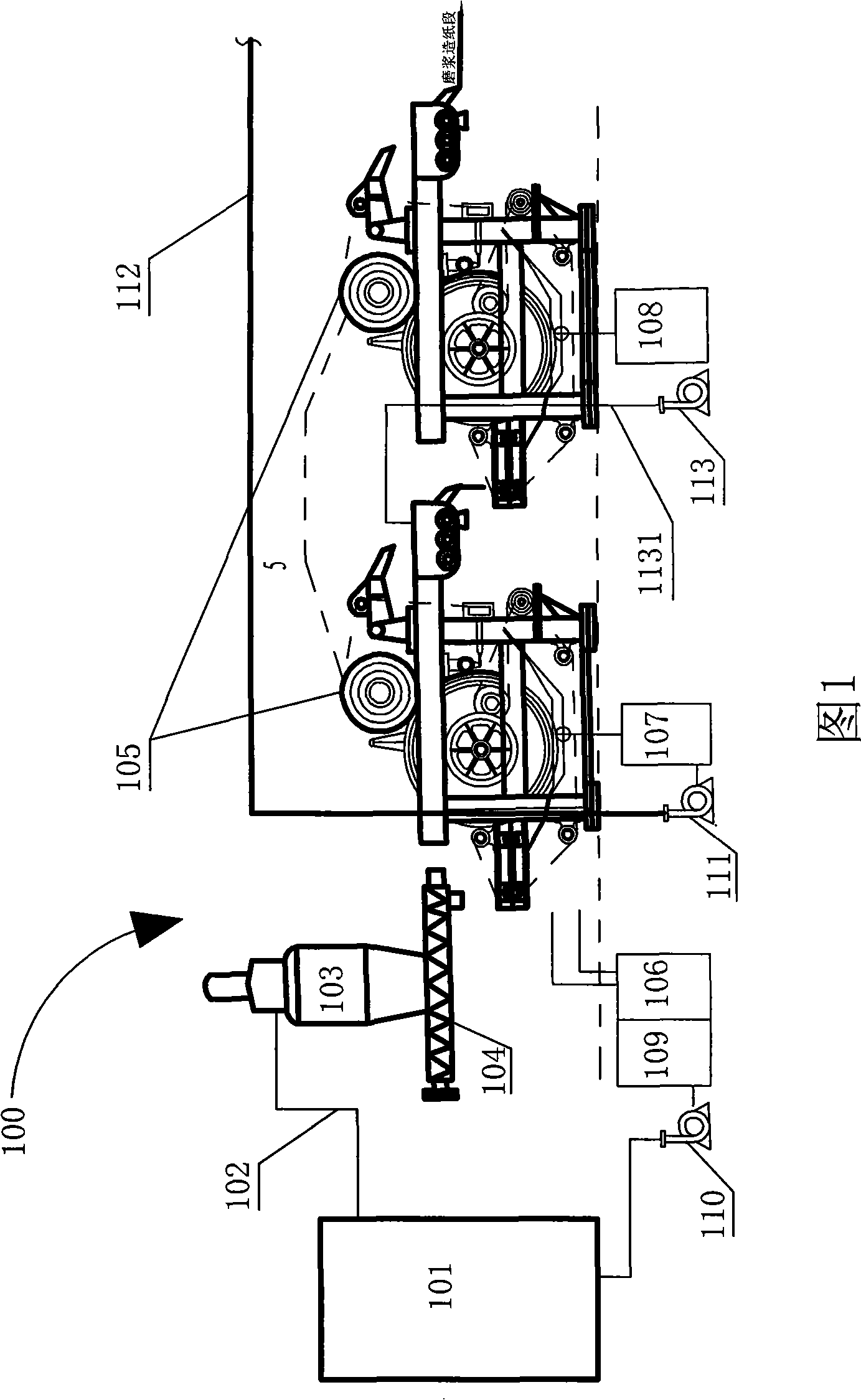

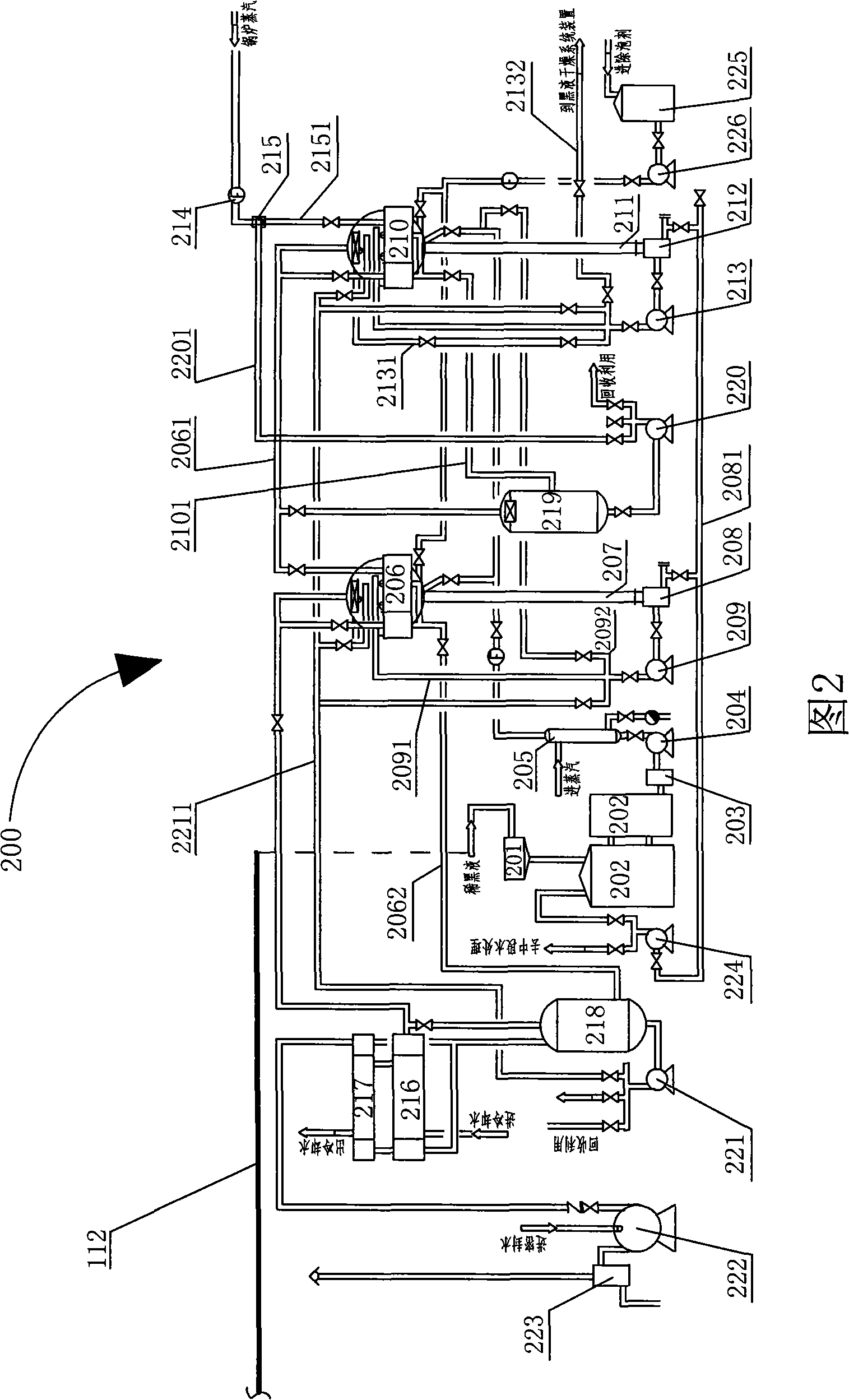

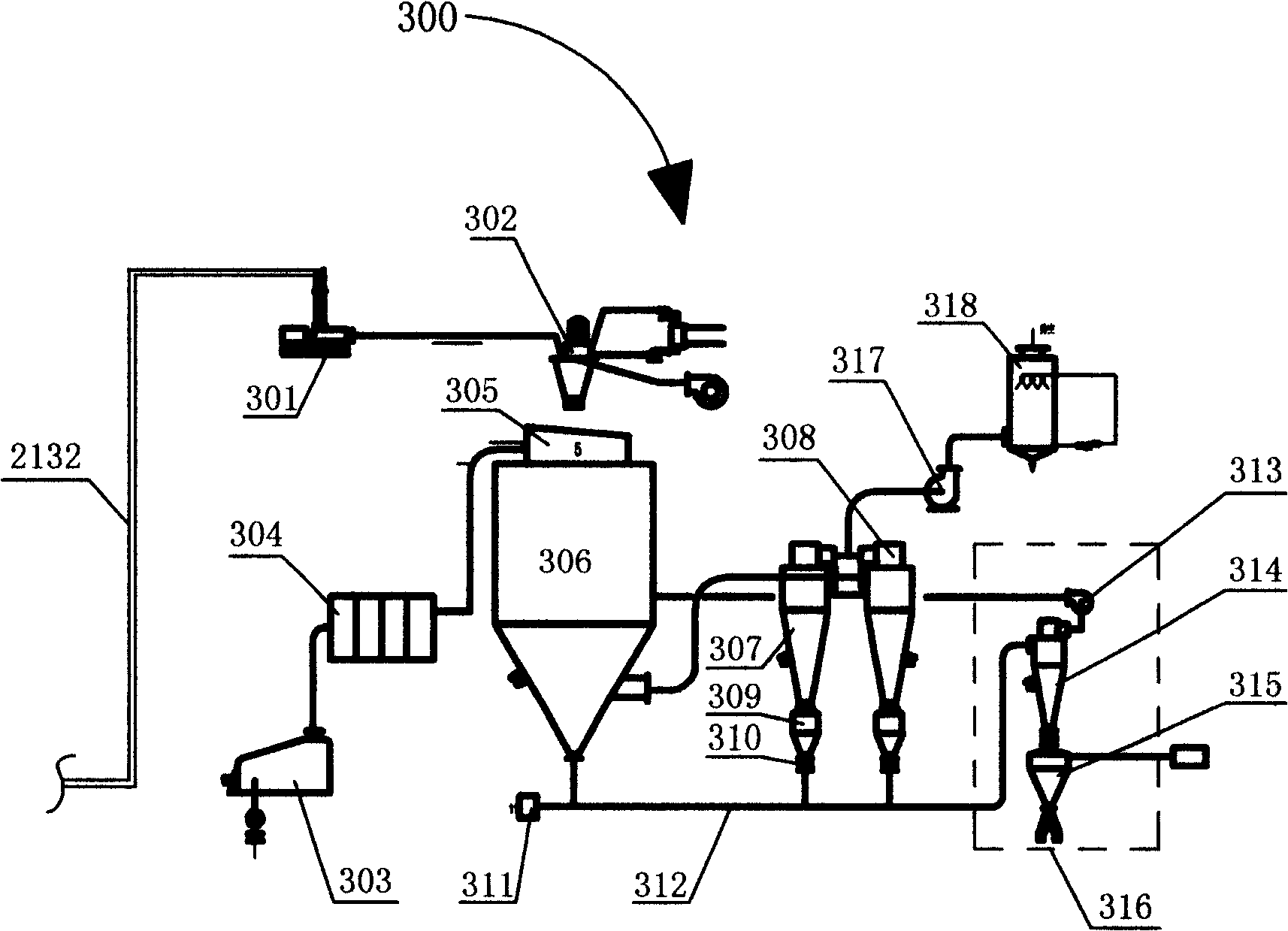

[0030] Referring to Figures 1 to 3, a device for extracting lignin from papermaking black liquor with zero discharge in the present invention includes a black liquor extraction system device 100, a black liquor concentration system device 200 and a black liquor drying system device 300;

[0031] The black liquor extraction system device includes a cooker 101, a spray pipe 102, a spray bin 103, a screw discharger 104, a black liquor extractor 105, a black liquor storage tank A 106, a black liquor storage tank B 107, Black liquor storage tank C 108, metering tank 109, black liquor pump A 110, black liquor pump B 111 and black liquor pump C 112; the cooker 101 is connected to the spray chamber 103 through the spray pipe 102; The bottom of the spray bin 103 is provided with a screw discharger 104, and the outlet of the screw discharger 104 is connected to the inlet of the black liquor extractor 105; , black liquor storage tank B 107, and black liquor storage tank C 108 are connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com