Reactor board and reaction treating method

A reaction container and reaction technology, applied in chemical instruments and methods, chemical method analysis, laboratory containers, etc., can solve the problems of foreign matter entering, polluting the external environment, etc., and achieve the effect of preventing cracks

Inactive Publication Date: 2008-10-15

SHIMADZU SEISAKUSHO CO LTD

View PDF3 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, there is a possibility that foreign matter enters the sample from the outside, and in turn, the reaction product will also pollute the external environment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Login to View More

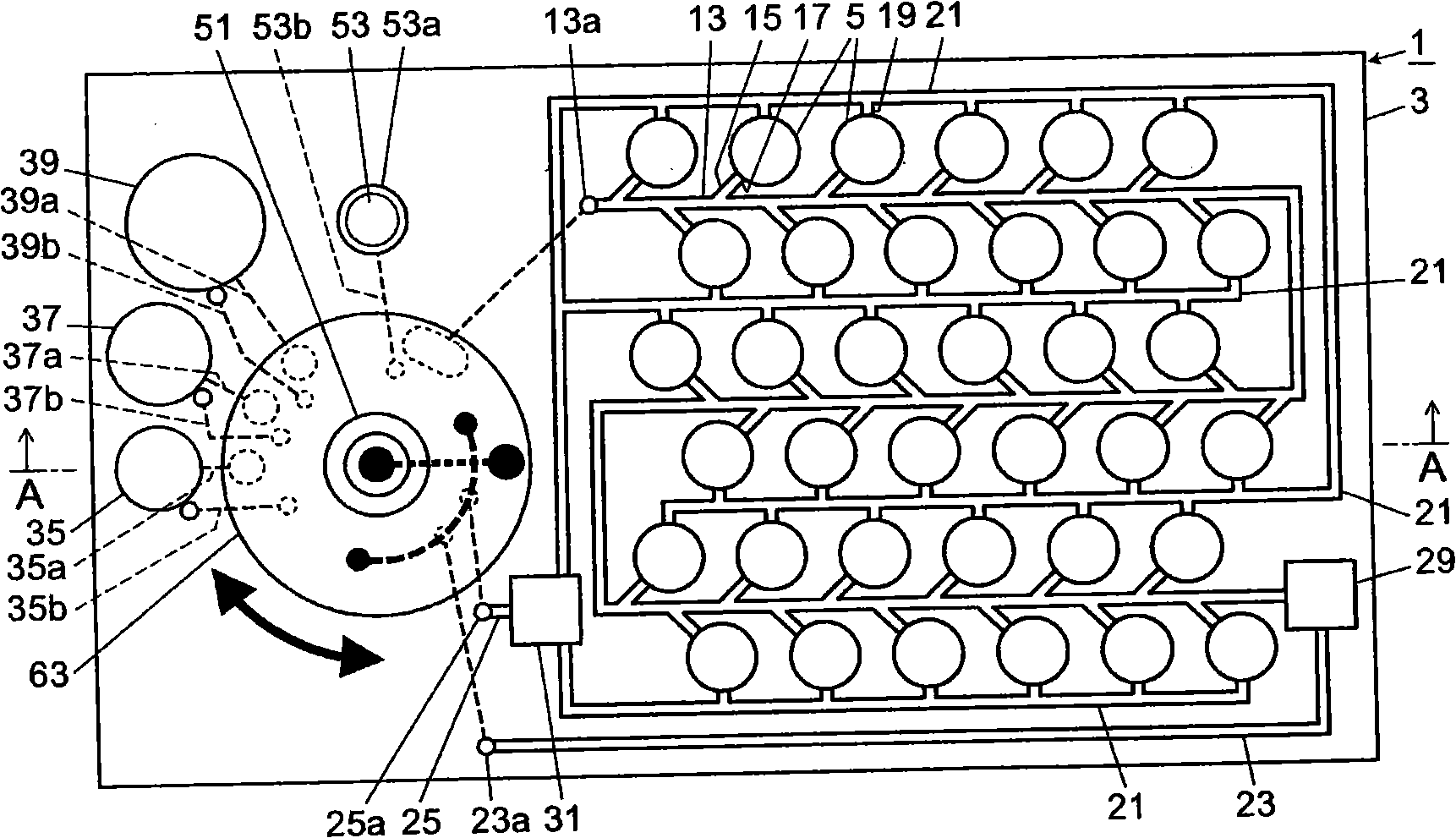

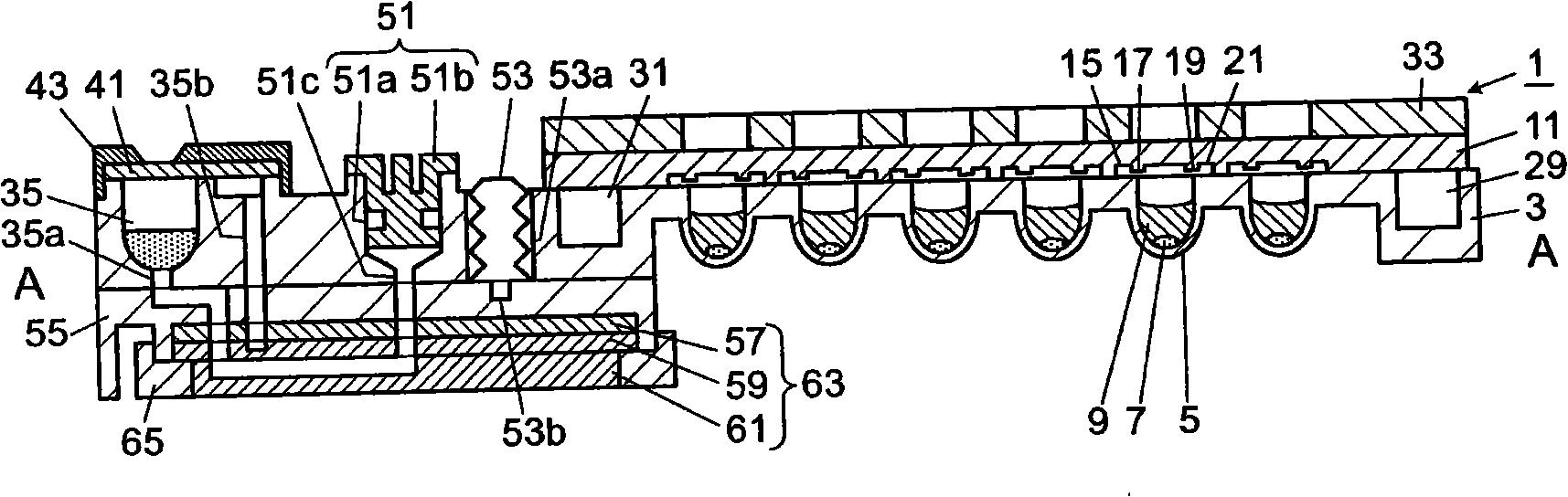

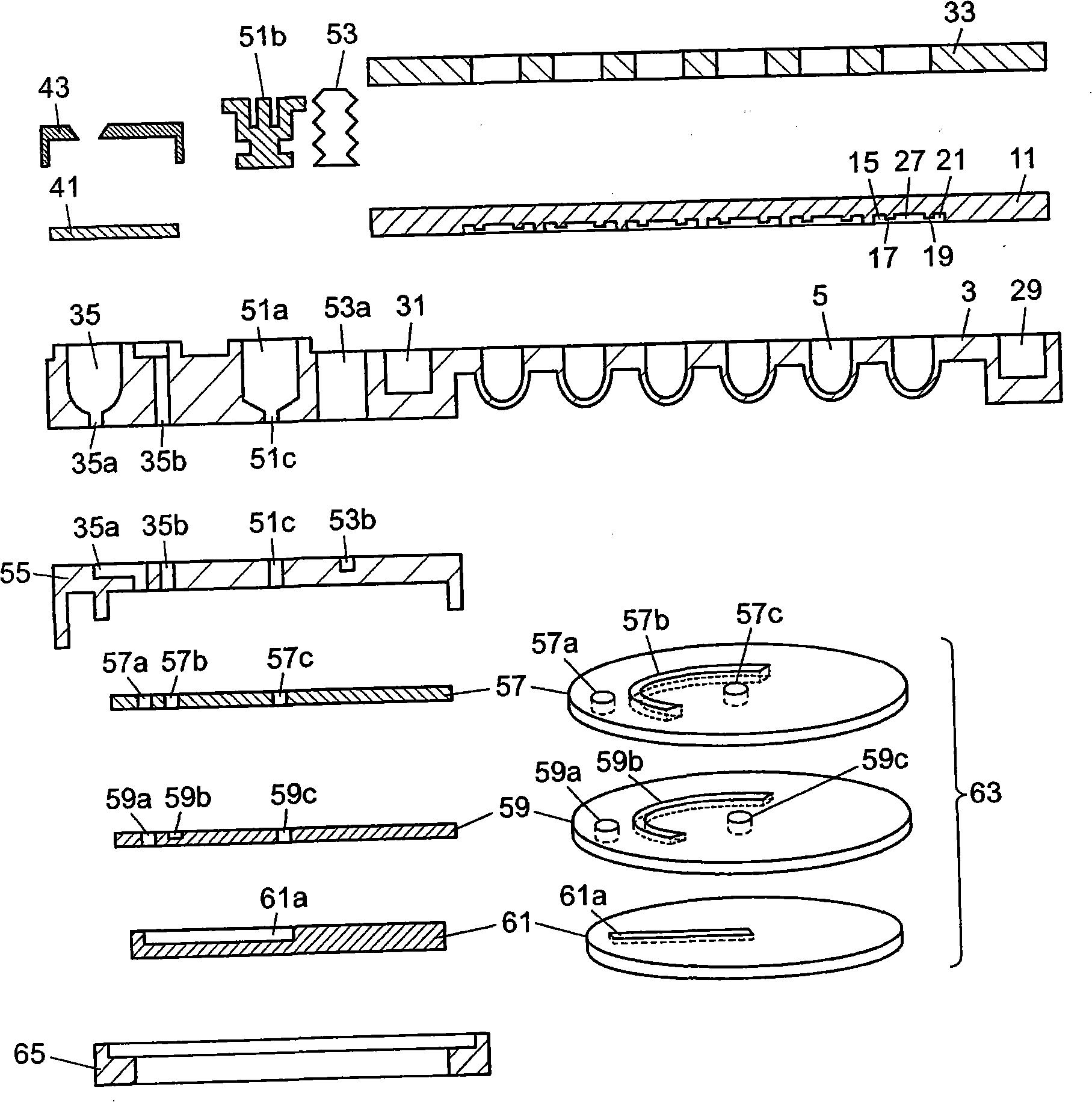

Abstract

The invention relates to a reaction vessel board, comprising a sealing reaction vessel, a reaction vessel stream connected with the reaction vessel and a reaction vessel exhaust stream connected with the reaction vessel. The reaction vessel is provided with a reagent held at the bottom and a solid heating melt material at normal temperature held at the bottom of the reaction vessel for sealing the reagent. When the sampling liquid and the reagent are reacted, the heating reaction vessel melts the heating melt material. The sampling liquid guided from the reaction vessel stream to the reaction vessel is reacted with the reagent in the reaction vessel.

Description

Reaction vessel plate and reaction processing method technical field The present invention relates to a reaction vessel plate suitable for performing various analyzes and analyzes in the general fields of biological analysis, biochemical analysis or chemical analysis, and in medical and chemical fields, and a reaction treatment method for treating the reaction vessel plate. Background technique As a small reaction device used in biochemical analysis, general chemical analysis, etc., a micro multi-chamber device is used. As such a device, for example, a micro-groove reaction vessel plate such as a micro-titer plate in which a plurality of grooves are formed on the surface of a flat substrate is used (see, for example, JP-A-2005-177749). In addition, as a micro-liquid weighing structure capable of quantitatively extracting a small amount of liquid, it includes a first flow path and a second flow path, a third flow path opened on the flow path wall of the first flow path, an...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N31/00G01N33/50C12Q1/68G01N21/00B01L3/00

CPCB01L3/5027B01L2200/0642B01L2200/10B01L2300/0829B01L2300/0864B01L2300/0874B01L2300/0887B01L2400/0622B01L2400/0644G01N2021/0325G01N2035/00158

Inventor 花房信博绪方是嗣

Owner SHIMADZU SEISAKUSHO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com