Double-worm wheel accurate transmission mechanism

A precision transmission, double worm gear technology, applied in the direction of gear transmission, transmission, hoisting device, etc., can solve the problems of driving efficiency and elimination of meshing backlash, large size of transmission mechanism, limited bearing capacity, etc., and achieve structural Wide range of design options, flexible and convenient use, and the effect of improving the carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

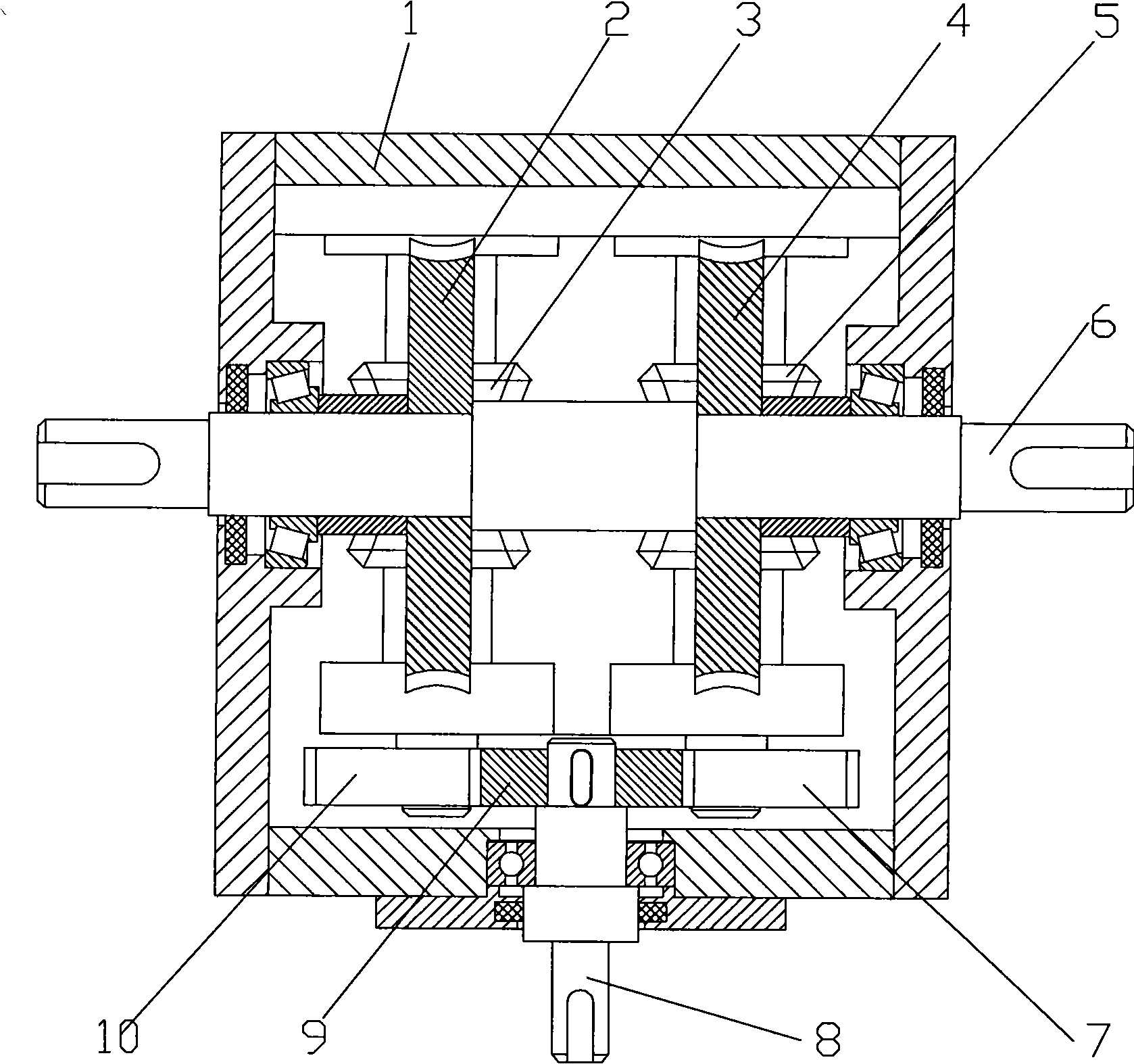

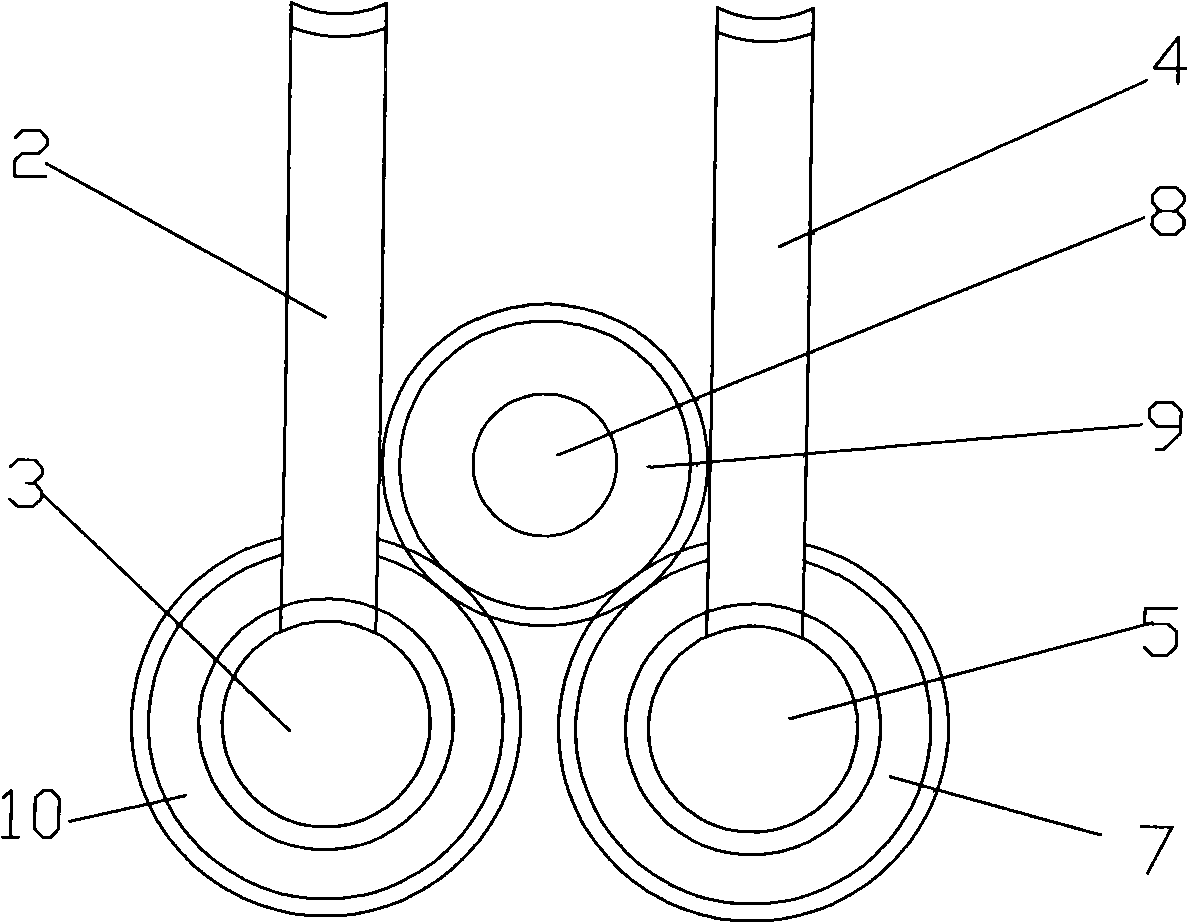

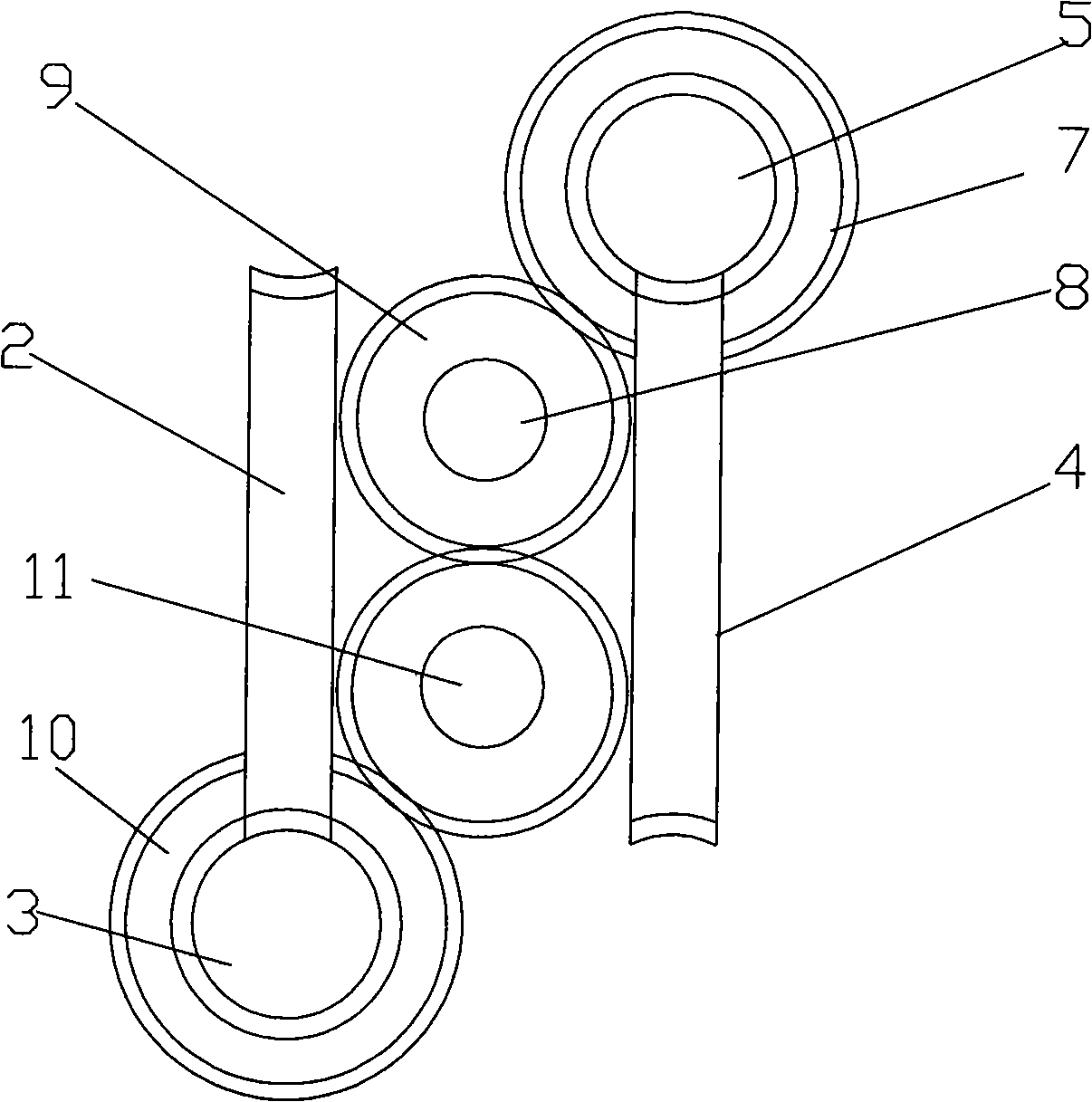

[0017] figure 1 It is a schematic cross-sectional view of the structure of the present invention, figure 2 It is a schematic diagram of worm I and worm II located on the same side of the power output shaft, as shown in the figure: the double worm gear precision transmission device of this embodiment includes a box body 1, a power input shaft 8 and a power output shaft 6, and also includes a worm gear transmission pair, worm gear and worm gap adjustment pair and gear transmission system, the lift angle of the worm gear and worm drive pair is greater than that of the worm gear and worm gap adjustment pair, and the lift angle of the worm gear and worm gap adjustment pair is smaller than the equivalent friction angle, so that the mechanism has self-locking properties, further To effectively control the backlash, that is, the backlash of the teeth, the worm gear and worm transmission pair should choose a larger lift angle to improve the transmission efficiency of the transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com