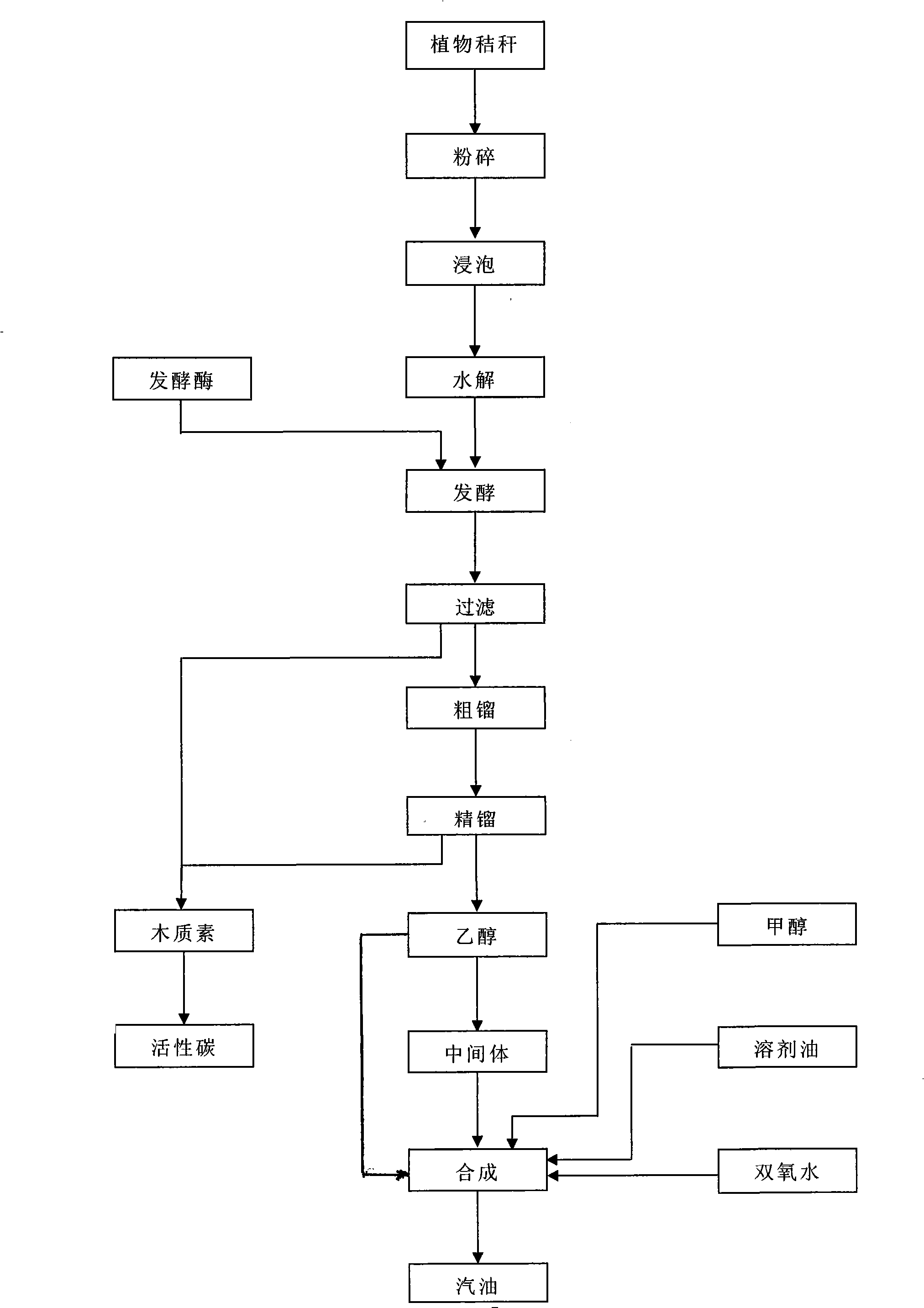

Technological process for preparing ethanol and synthetic gasoline from plant straw

A process method and ethanol technology, which are applied in the petroleum industry, biofuels, liquid carbon-containing fuels, etc., can solve the problems of insignificant energy saving effect, shortage of feed production raw materials for poultry and livestock, shortage of corn, etc., and achieve considerable economic benefits. The effect of alleviating energy shortage and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The invention is adopted to construct a synthetic gasoline enterprise. First of all, the site of the factory should be selected on the river beach sandy land far away from the residential area, or in the saline-alkaline area; in order to ensure safety, the building must be 500m away from the factory; in order to ensure the freshness of the Chinese herbal medicine, the factory site for the preparation of fermented enzymes should be selected at a distance from the raw materials. The location that the production center is near.

[0024] Process method of the present invention is specifically described as follows in conjunction with accompanying drawing:

[0025] The process for preparing ethanol in the present invention is made of plant stalks as raw materials, which are composed of crushing, soaking, hydrolysis, fermentation, filtration, rough distillation, and rectification. After the raw materials of corn stalks or straws are cleaned, they enter the crushing process , ...

Embodiment 2

[0029] Using the present invention to prepare ethanol and synthesize gasoline, sweet sorghum stalks or rice straw are selected as raw materials; after soaking the materials to remove 20% of water, they are put into a boiling tank for heating and boiling, and the temperature is controlled at 130°C for hydrolysis. 8 hours, heat preservation for 4 hours; the temperature in the tank of the fermentation process is 28°C; the crude distillation temperature is 90°C, and the ethanol concentration of the distillate is 78%; enter the rectification process, the temperature is controlled at 100°C, and the ethanol concentration of the distillate reaches 99%.

[0030] The ingredients for the preparation of fermented enzymes are 80kg of wolf’s tail grass, 10kg of dried yam, 5kg of wheat germ, and 5kg of barley malt; the preparation process is to first cut the wolf’s tail grass into powder, boil it in water, and cool it for later use; then grind the dried yam and malt Put it into fine powder an...

Embodiment 3

[0034] Use tree branches, or bark, or sawdust as raw materials to prepare synthetic gasoline. After the material is soaked, 25% of the water is removed, and then transferred to the boiling tank, the temperature is controlled at 110°C; the crude distillation temperature is 88°C, and the output ethanol concentration is 75%; the rectification temperature is 98°C, and the output ethanol concentration is 97%; the raw materials for fermentation enzyme preparation are 60kg of wolftail grass, 10kg of dry yam, 15kg of wheat malt and barley malt respectively; transfer to the fermentation room, keep a constant temperature of 45°C for 15 days; the raw materials of the synthesis process are 250kg of ethanol and 250kg of methanol , 200kg of intermediate, 250kg of No. 120 solvent oil, 50kg of 5% hydrogen peroxide, fully stirred evenly, and synthetic gasoline can also be produced. Other technological conditions are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com