Method for preparing phenolic compound with biomass

A technology of phenolic compounds and biomass, applied in the field of biomass preparation of phenolic compounds, can solve the problems of complex process, serious pollution, high cost, etc., and achieve the effect of improving reaction efficiency and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Mix 5g corn stalk powder (length 0.180mm) with 0.75ml water uniformly, add it into a 10ml miniature airtight reactor, raise the temperature to 350°C at a heating rate of 30°C / min, and keep it at this temperature for 30 minutes. After the reaction is cooled, the residue is distilled at a temperature of 101-450°C, the product is separated by condensation, the oil phase product is separated and extracted with acetone, and the composition of the extract is analyzed by gas quality online. Phenolic compounds account for 36.21% of the total composition.

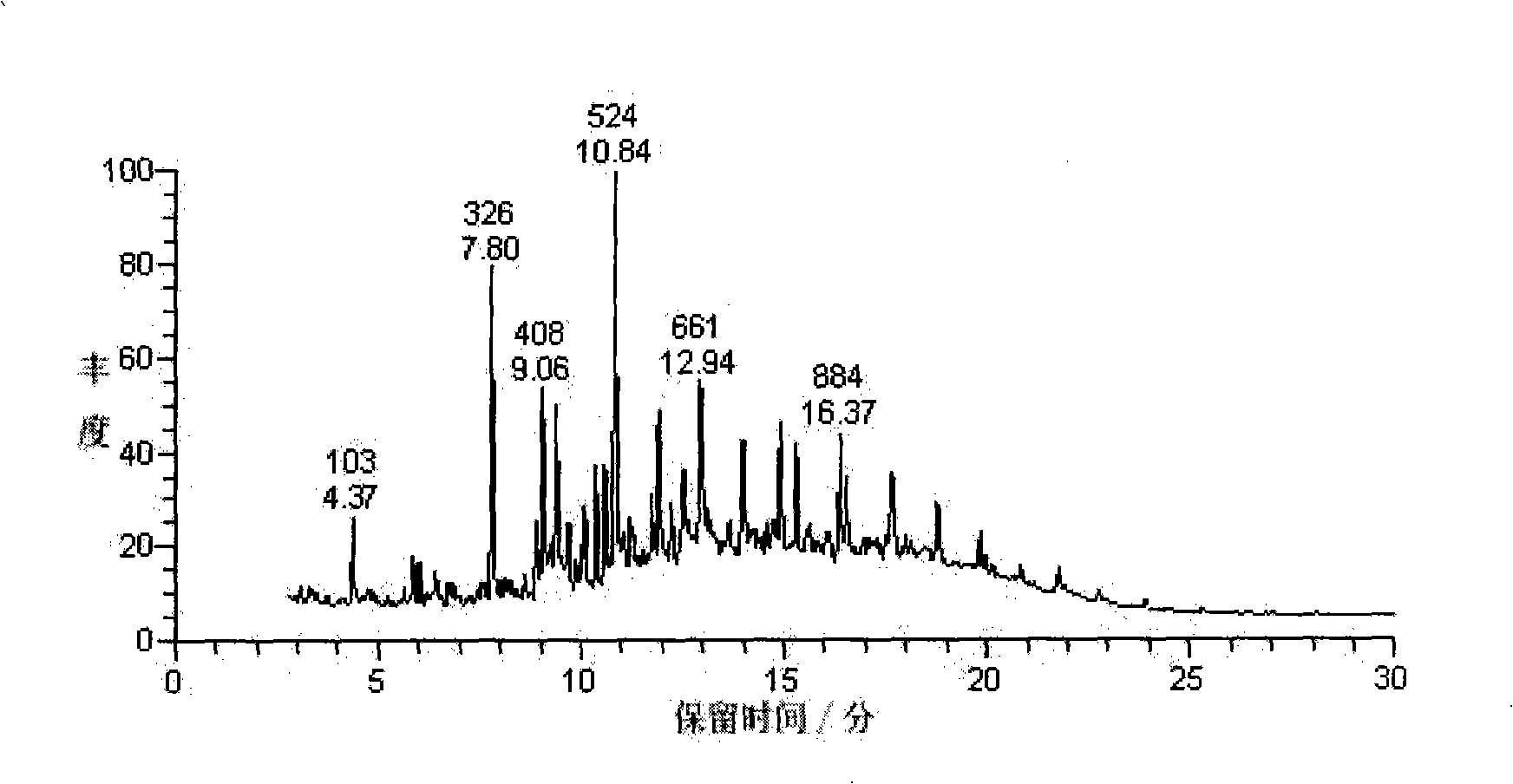

[0016] figure 1 It is the chromatographic peak of the obtained liquid product. According to the results of mass spectrometry peak analysis, the main components of phenolic compounds in the obtained liquid phase product are:

[0017] Phenol, 2-methylphenol, 4-methylphenol, 2-ethylphenol, 3,5-dimethylphenol, 4-ethylphenol, 5-methyl-2-ethylphenol, 5-methyl -2-ethylphenol, 5-methyl-3-ethylphenol and 4-methyl-2-ethylphenol.

[0018]...

Embodiment 2

[0020] Mix 300g of cotton straw powder (length 0.150mm) with 60ml of water, and add it to a 2kg / h-level airtight small test device. The screw extruder rotates at 900 rpm, and the temperature is raised to 15℃ / min. At 380°C, it is maintained at this temperature for 40 minutes after the feeding is completed. The residue was distilled in a 100ml closed reactor at a temperature of 25-450°C, the product was separated by condensation, the oil phase product was separated and extracted with acetone, and the composition of the extract was analyzed by gas quality online. Phenolic compounds accounted for 42.97% of the total components.

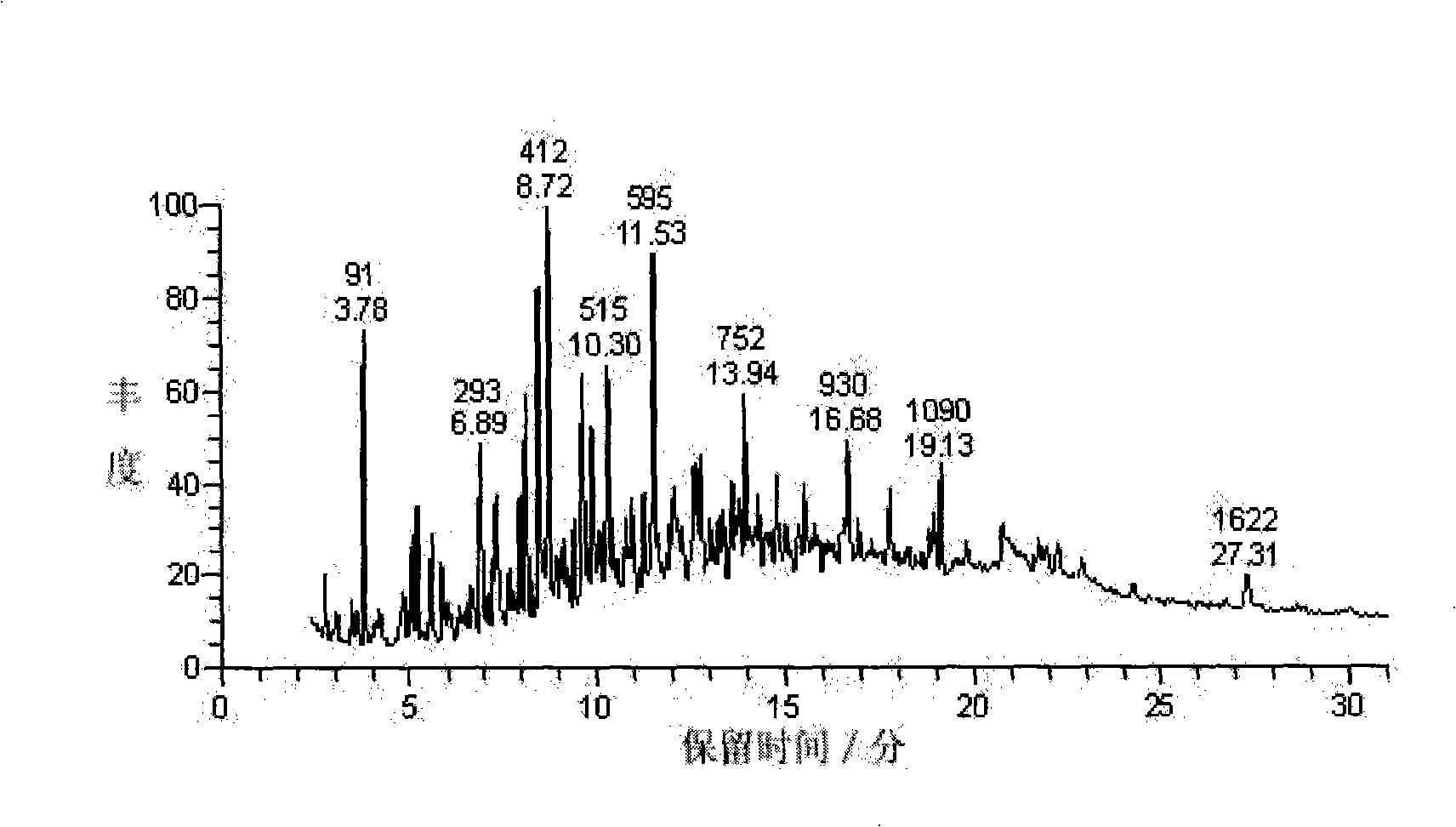

[0021] figure 2 It is the chromatographic peak of the obtained liquid product. According to the results of mass spectrometry peak analysis, the main components of phenolic compounds in the obtained liquid phase product are:

[0022] Phenol, 2-methylphenol, 4-methylphenol, 2-methoxyphenol, 3,4-dimethylphenol, 3-ethylphenol, 4-methyl-2-methoxyphenol, 4- Ethyl-...

Embodiment 3

[0025] Mix 5g wheat straw powder (length 0.180mm) with 1ml water uniformly, add it to a 10ml miniature airtight reactor, raise the temperature to 370°C at a heating rate of 30°C / min, and keep it at this temperature for 30 minutes. After the reaction is cooled, the residue is distilled at a temperature of 100 to 430°C, the product is separated by condensation, the oil phase product is separated and extracted with acetone, and the composition of the extract is analyzed by gas quality online. Phenolic compounds account for 33.05% of the total composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com