Water source heat pump units capable of automatically backwashing sewage water

A water source heat pump unit and backwashing technology, which is applied in the direction of compressors, heat pumps, and refrigerators with reversible circulation, can solve the problems of immature groundwater recharge technology, pollution and damage of groundwater resources, and increase the heat exchange temperature difference of heat exchangers. and other problems, to achieve the effect of improving unit efficiency, saving equipment costs, and reducing heat transfer temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

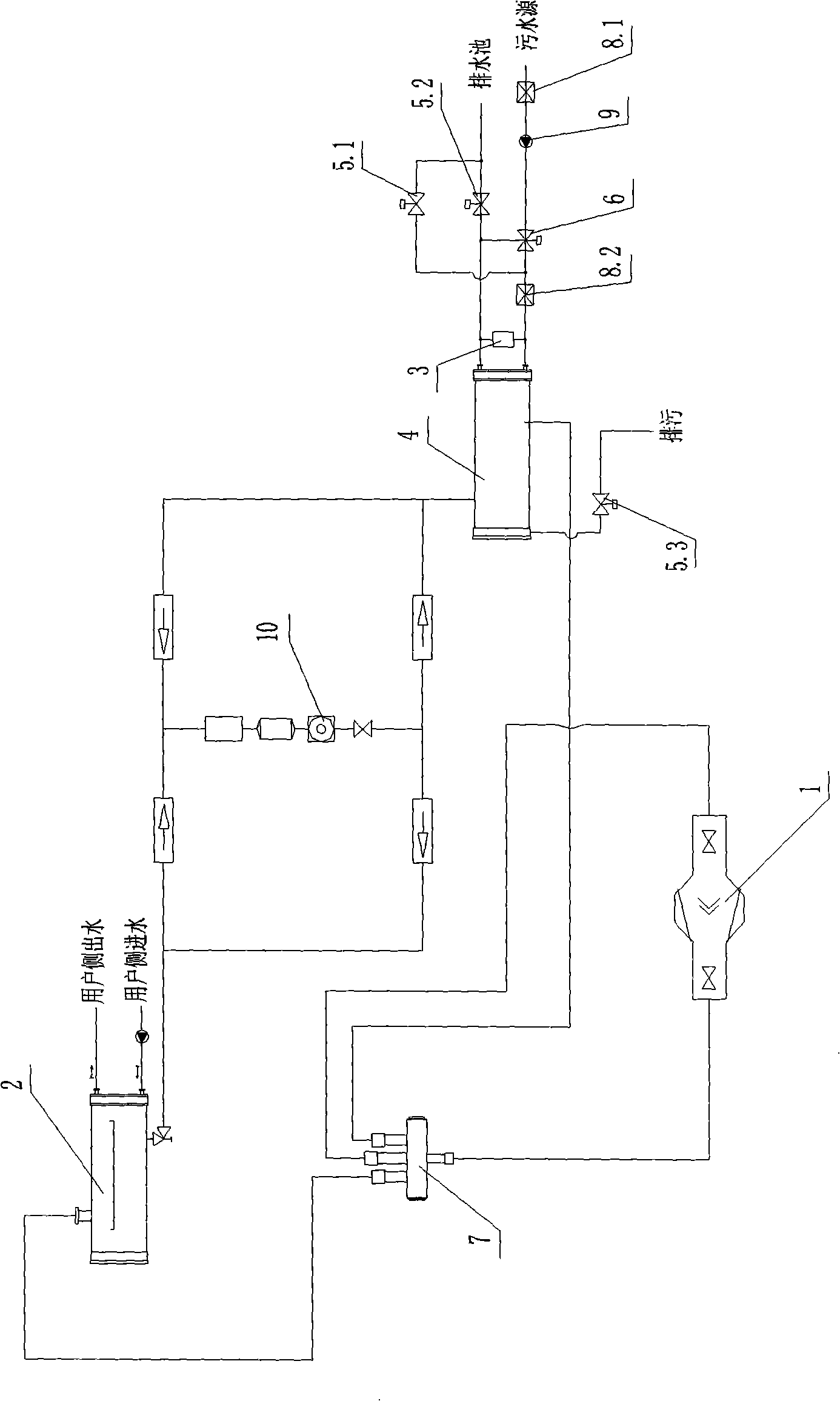

[0014] Referring to the accompanying drawings, the present invention includes a compression evaporation condensation unit composed of a compressor 1 , a condenser 2 , an expansion valve 10 , an evaporator 4 and a four-way valve 7 . Both the condenser 2 and the evaporator 4 are flooded water heat exchangers, in which the heat exchange tubes are made of anti-corrosion white copper, and the end caps at both ends of the condenser 2 and the evaporator 4 are built with highly reducing metals. A filter one 8.1, a water pump 9, a three-way valve 6 and a filter two 8.2 connected to the sewage source are sequentially connected in series on the water supply pipeline of the evaporator 4. The return water pipeline of evaporator 4 is connected in series with the electric valve two 5.2 that is connected with drainage tank. A differential pressure sensor 3 is connected in parallel between the inlet and outlet of the evaporator 4 . An electric valve one 5.1 is connected in parallel between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com