High temperature hot pipe center receiver for tower type solar energy heat power generation

A technology of tower-type solar energy and high-temperature heat pipes, applied in solar thermal power generation, solar collectors, solar thermal energy, etc., can solve the problems of waste of high-temperature heat pipes, limited heat transfer capacity of receivers, and small heat transfer coefficients to avoid empty space High-temperature heat pipe, convenient design and adaptability, and the effect of improving heat transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

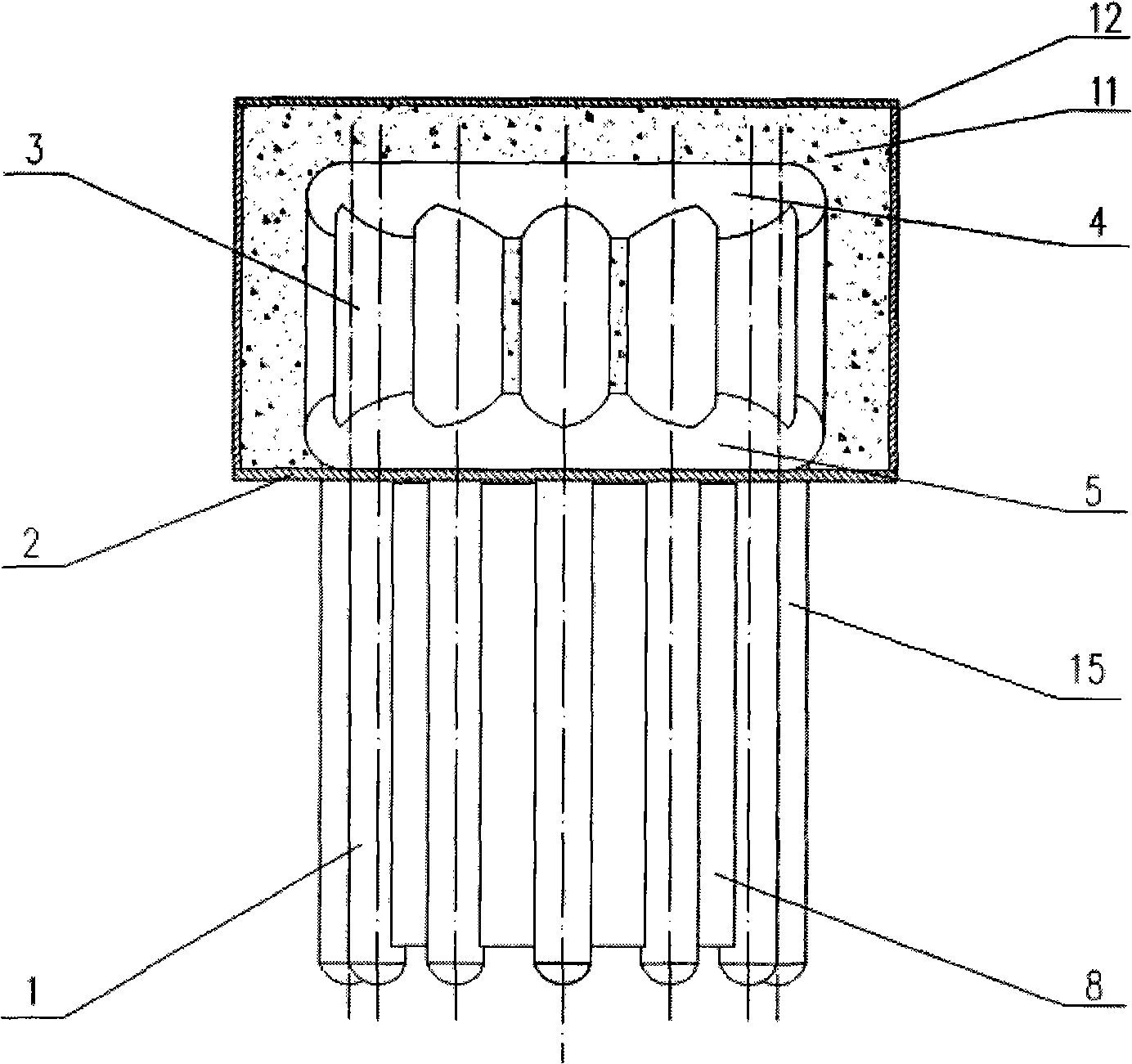

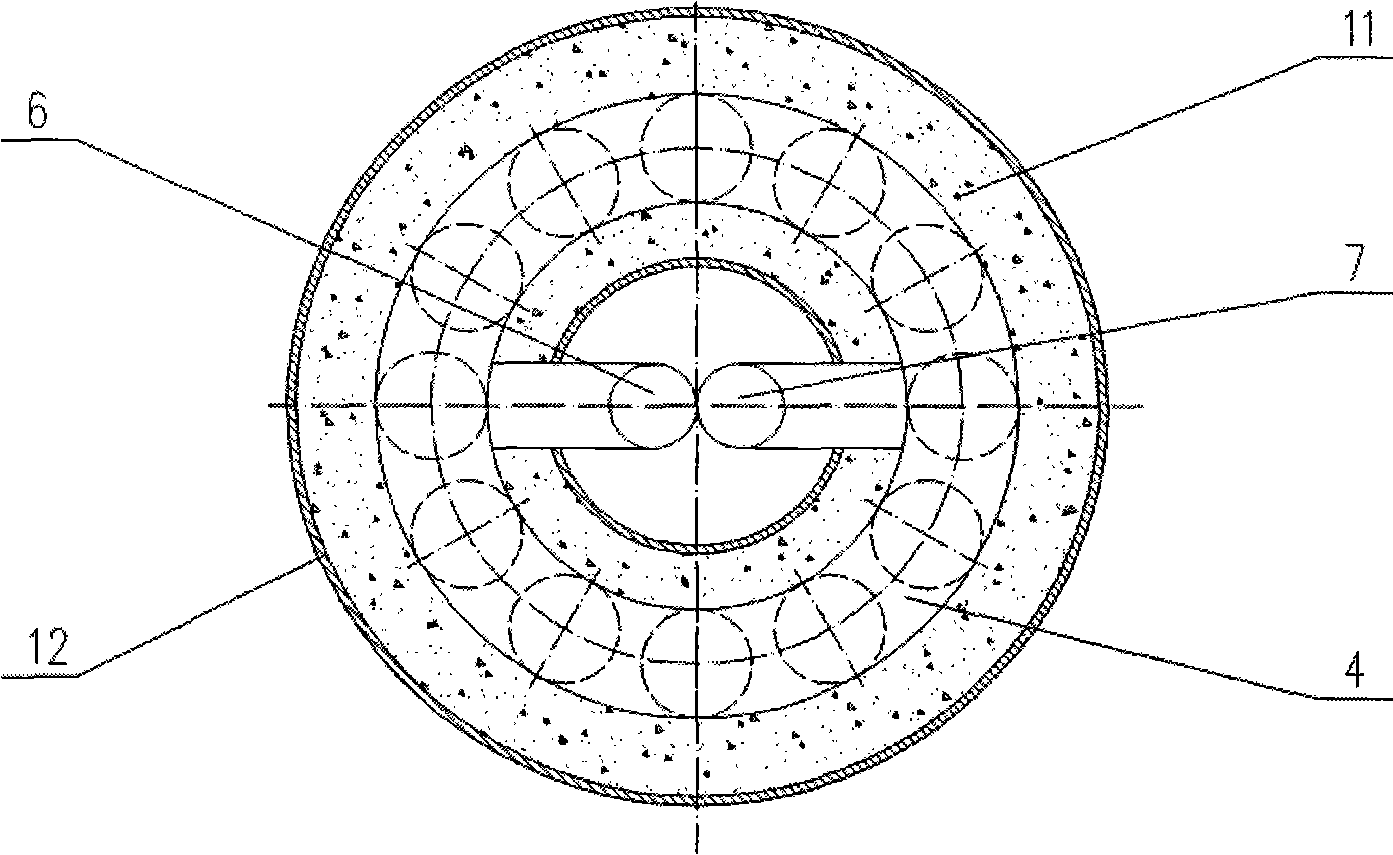

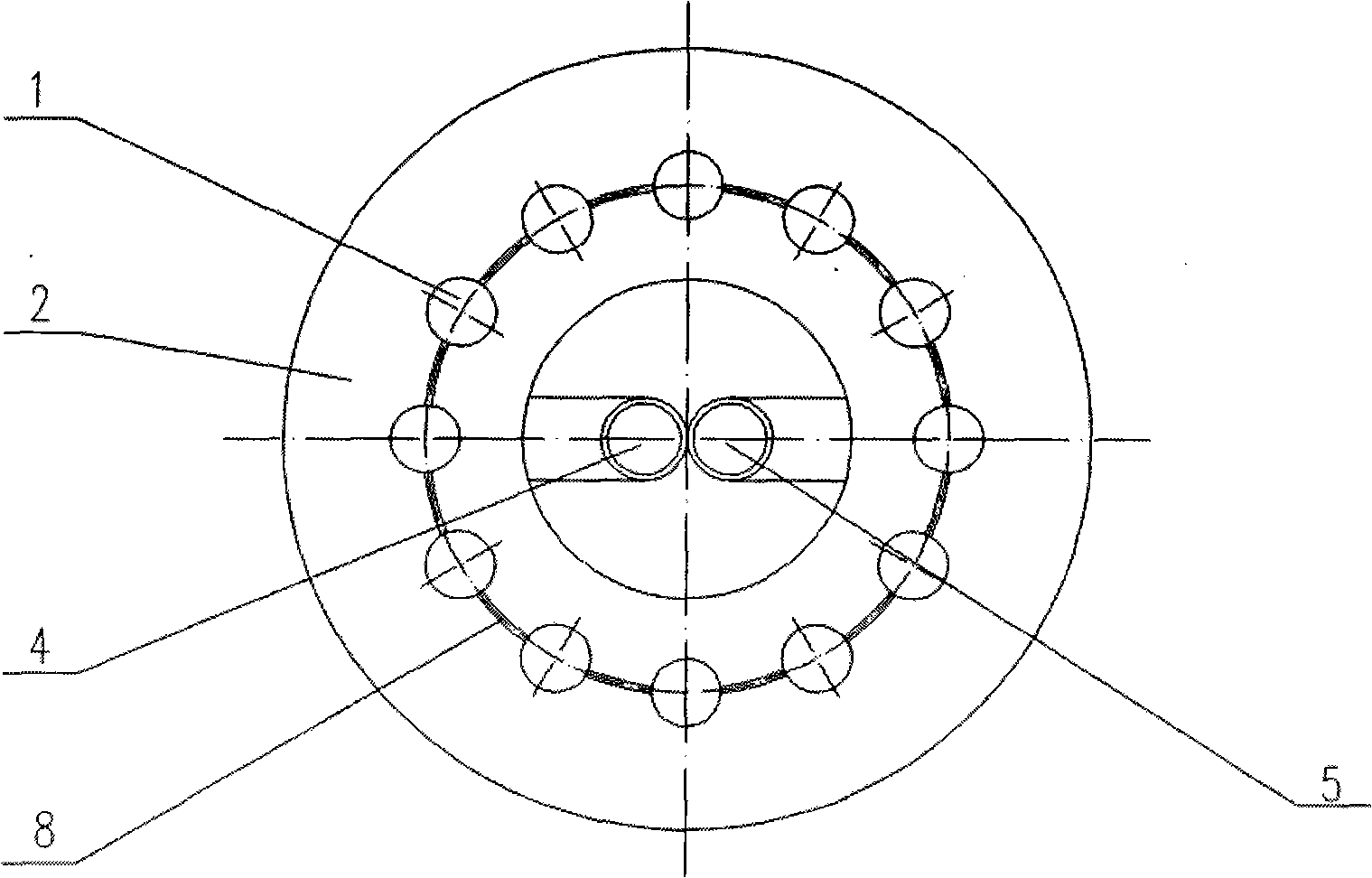

[0020] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the structure of the high-temperature heat pipe central receiver 13 of the present invention includes several high-temperature heat pipes 1, and the annular tube plate 2 separates the high-temperature heat pipes 1 into two parts, the heat-absorbing section and the heat-dissipating section, and the casing for heat exchange of the working fluid 3 The upper header pipe 4, the lower header pipe 5, the working fluid inlet pipe 6 and the working fluid outlet pipe 7 connected as an integral channel; the part of the high-temperature heat pipe 1 located in the casing 3 is the heat release section, which is located under the annular tube plate 2 The part is the heat absorption section, and the heat absorption sections of every two adjacent high-temperature heat pipes are connected by straight fins 8; the outer surface of the heat absorption section of the high-temperature heat pipe 1 and the surface of the straight fins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com