Rolling rotor type cold compressor

A rolling rotor type, refrigeration compressor technology, applied in the field of refrigeration compressors, can solve problems such as ammonia corrosion to copper, inability to use ammonia, etc., and achieve the effects of good environmental protection, long service life and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

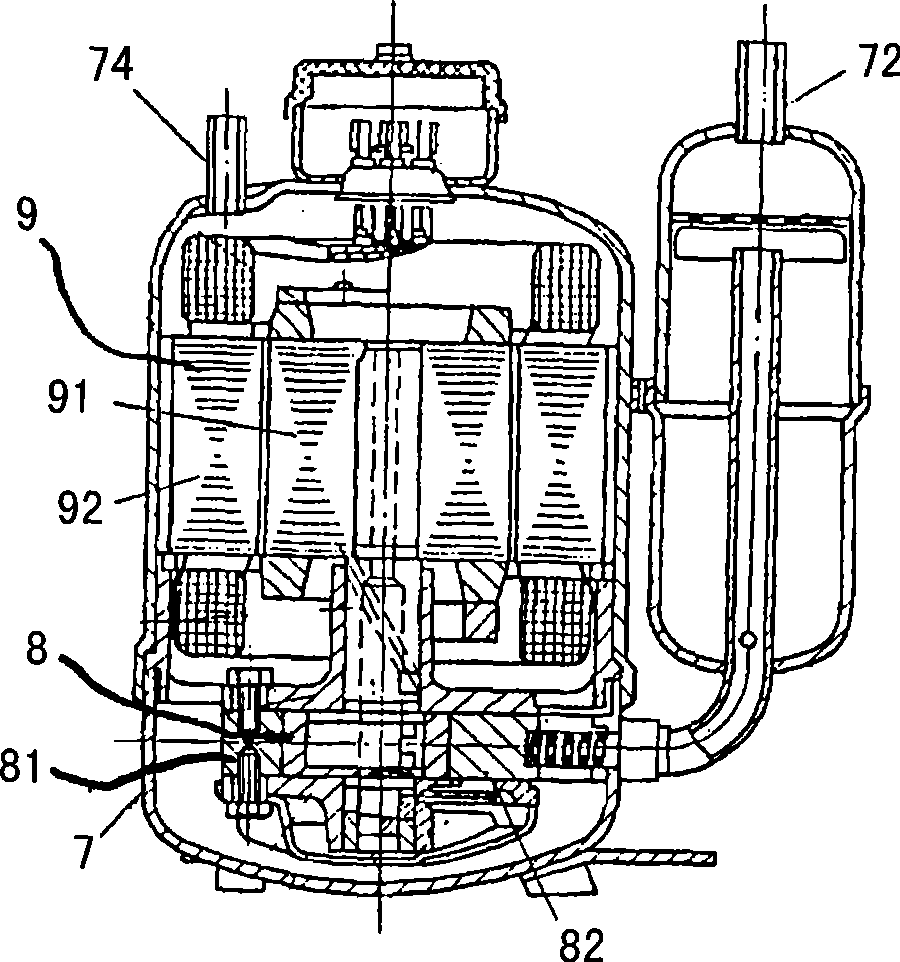

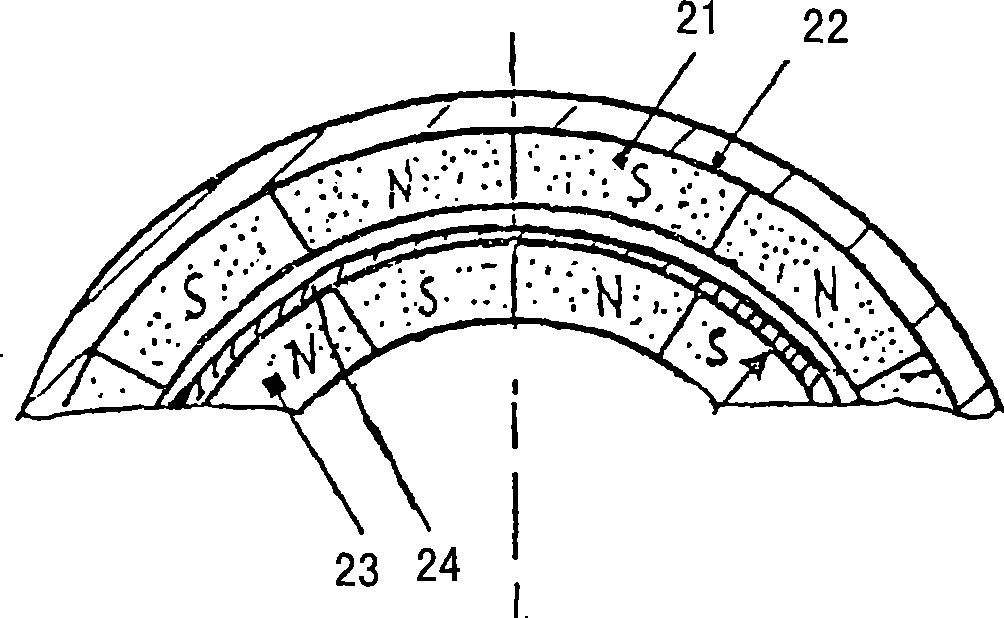

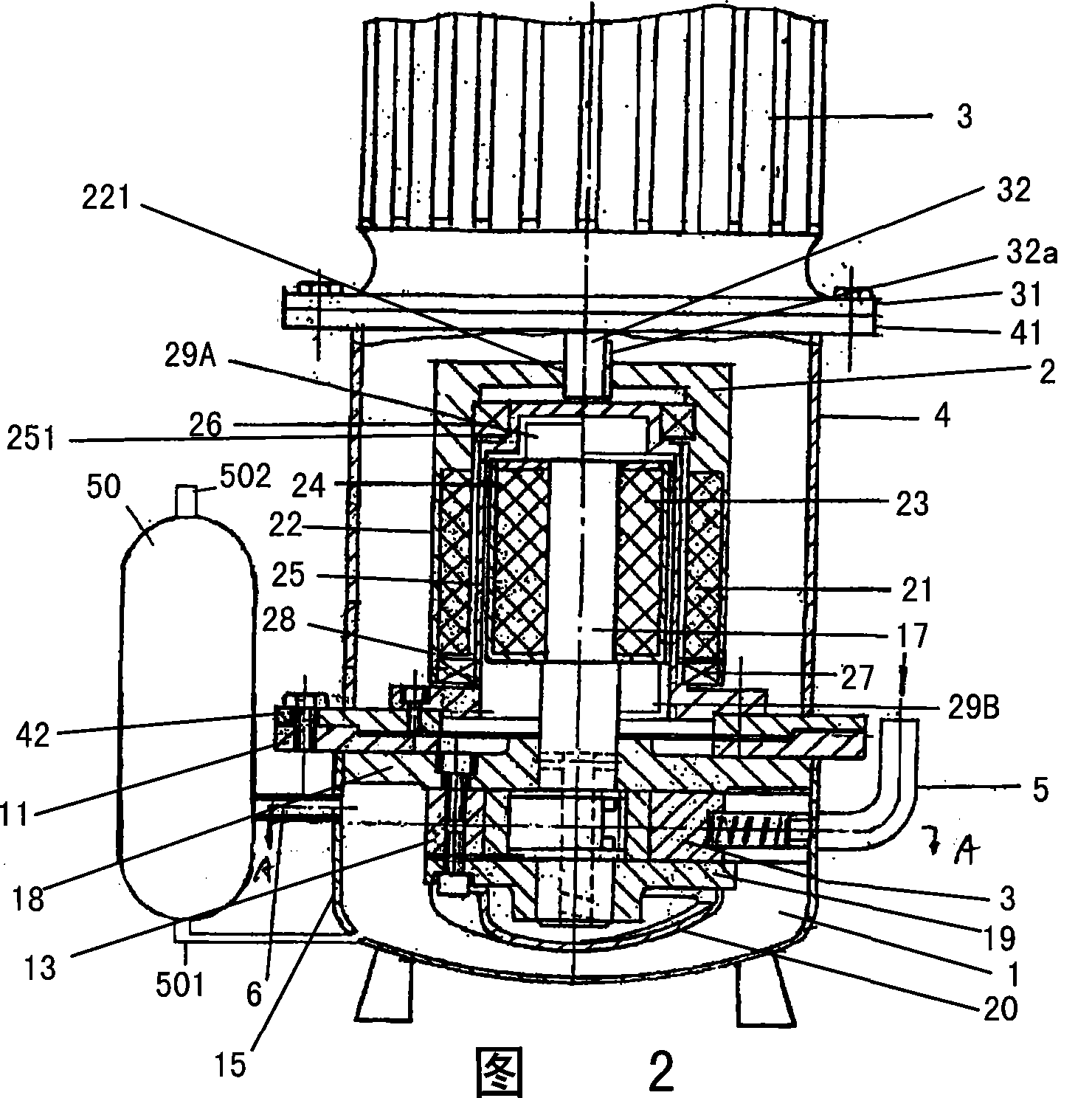

[0013] figure 2 It is a schematic diagram of the structure of the rolling rotor refrigeration compressor of the present invention. The refrigeration compressor of the present invention includes an electric motor 3, a magnetic coupling 2 and a compression device 1. The electric motor 3, the magnetic coupling 2 and the compression device 1 are arranged vertically from top to bottom. A flange 31 is provided at the lower end of the motor 3. A coupling housing 4 is provided outside the magnetic coupling 2, and the coupling housing 4 protects and supports the magnetic coupling 2. The upper end of the coupling housing 4 is provided with a flange 41 that matches the flange 31, and the motor 3 and the coupling housing 4 are fastened together by bolts through the flange 31 and the flange 41. The magnetic coupling 2 includes an outer magnet 21, an outer magnet protective sleeve 22, an inner magnet 23, an inner magnet protective sleeve 24, a shield sleeve 25, an upper bearing 26 and a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com