Low speed vacuum squeeze casting technology

A casting process and vacuum pressure technology, which is applied in the field of full vertical die casting process, can solve the problems of strict mold heat balance and temperature field, difficult maintenance of double punches, and limited application range, so as to avoid vacuum shrinkage defects, Reduce the probability of internal porosity and shrinkage defects, and reduce the effect of porosity and porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

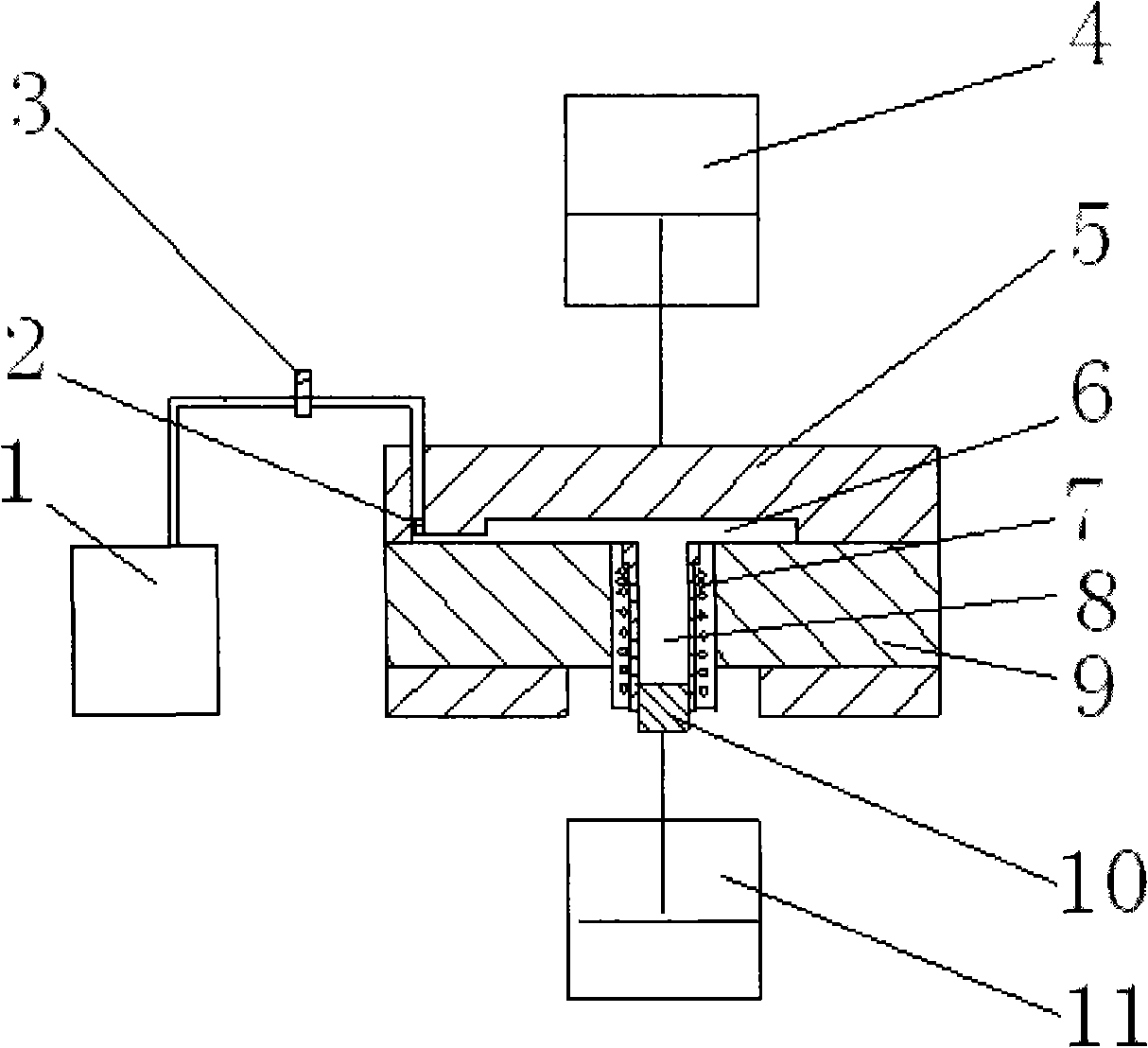

[0007] Such as figure 1 Shown, the process steps of the present invention are (1) mould, vacuum system and hot runner design: the requirement of mold design is: ingate thickness is 6-12mm thicker than common die-casting mould, when ingate is opened on casting thick-walled (18-25mm), it can be 15-18mm; the location of the installation of the hot runner should consider the safety of electricity and be more than 200mm away from the injection cylinder 11; the requirements for the design of the hot runner are: the heater 7 is divided into multiple groups, They are respectively controlled by different temperature controllers. The special requirements for the design of the vacuum system are: the displacement of the vacuum pump and the volume of the vacuum tank 1 should be determined according to the volume of the cavity 6 to ensure that the cavity vacuum reaches -0.09MPa or higher within 3 seconds. The performance of the plug 2 must ensure that the cavity 6 is quickly connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com