Method for synthesizing non-metal catalyst self-organizing growth carbon nano-tube with chemical vapor deposition

A technology of chemical vapor deposition and carbon nanotubes, which is applied in the direction of carbon nanotubes, nanotechnology for materials and surface science, nanocarbon, etc., can solve the problems of high production cost, high growth temperature, and many impurities in the product, and achieve Realize the effects of continuous production, low preparation cost and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

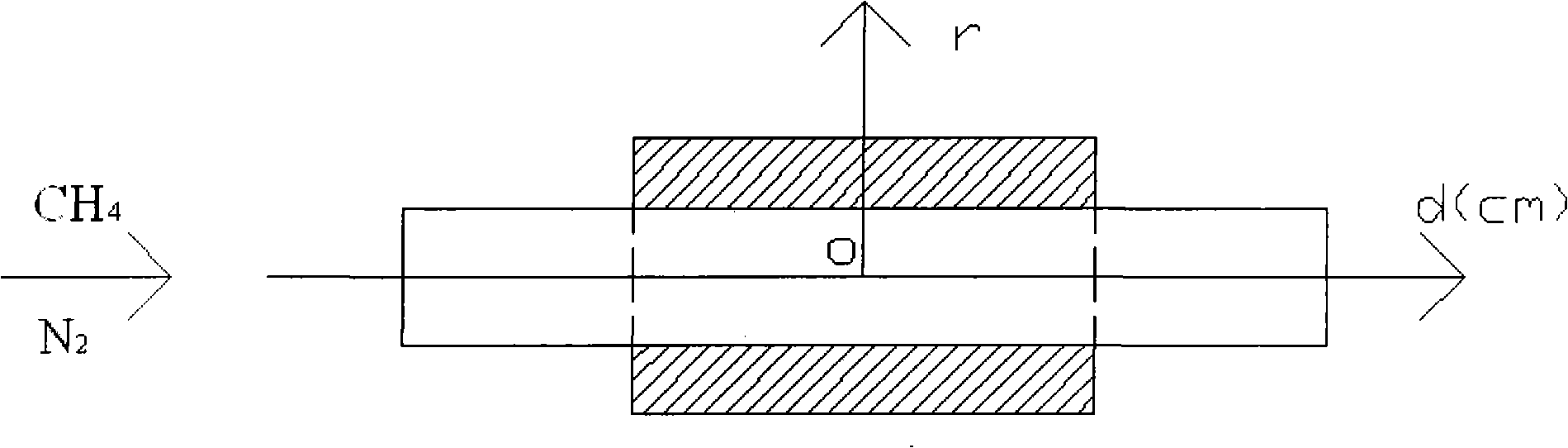

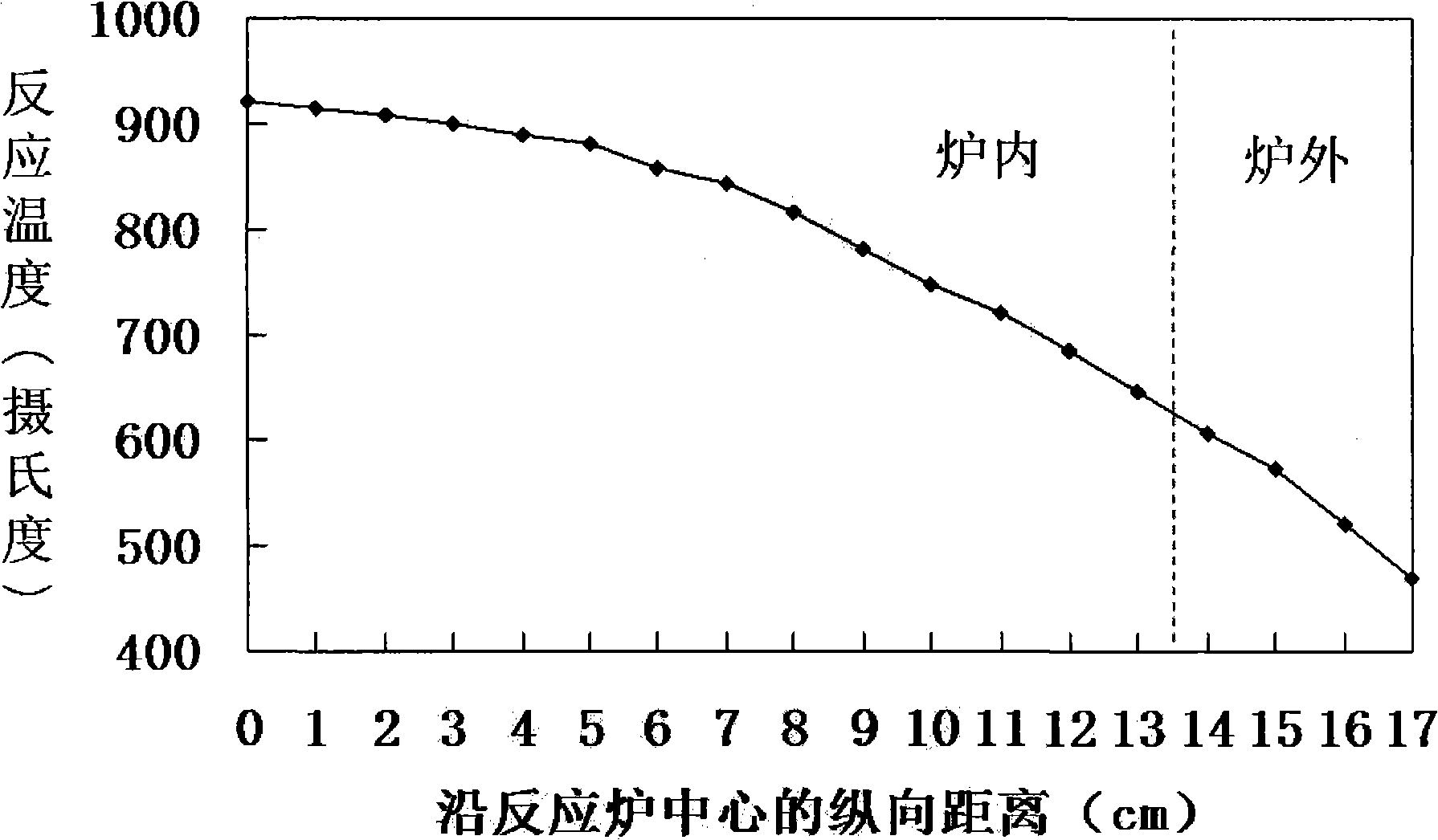

[0025] Such as figure 1 , the equipment used in this example is a horizontal vacuum tube furnace. Under the protection of the carrier gas, the temperature is raised to 940 ° C ~ 980 ° C, and the carbon source gas is introduced. The carbon source is cracked when it flows through the high temperature area, and the substrate in the low temperature area deposition to form carbon nanotubes. Such as figure 2 , r represents the diameter of the corundum tube of the horizontal vacuum tube furnace. There is a temperature gradient between the central part of the high-temperature furnace cavity used in this embodiment and the position where the substrate is placed. When the high-temperature furnace is heated to the programmed temperature (such as 950°C , the temperature at the center of the cavity is 920°C (30°C lower than the programmed temperature, as shown in Table 1), and the temperature at the position where the substrate is placed is about 650°C to 750°C. This temperature gradient...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com