Method for extracting nickel and/or cobalt

A nickel-cobalt leaching technology, applied in the field of extracting nickel and/or cobalt, cobalt, extracting nickel, or nickel and cobalt, can solve the problems of long leaching cycle, using more equipment, and slow infiltration speed, so as to avoid heap The effect of extremely slow leaching speed, short leaching cycle, and fast leaching speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] best practice

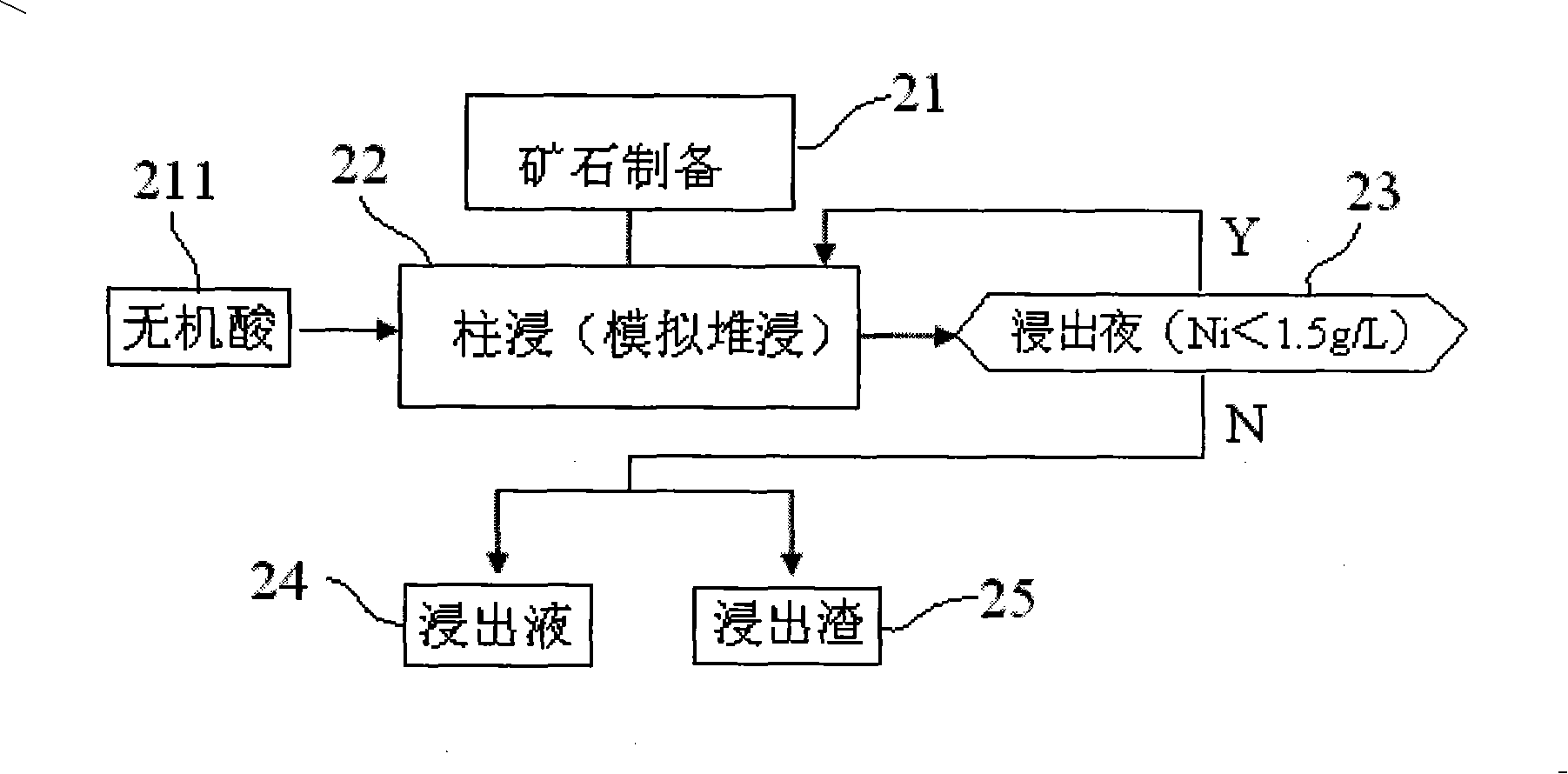

[0032] The inventors found that in the heap leaching process, the serpentine-type ore has a shorter leaching period; while the limonite-type ore has a longer leaching period.

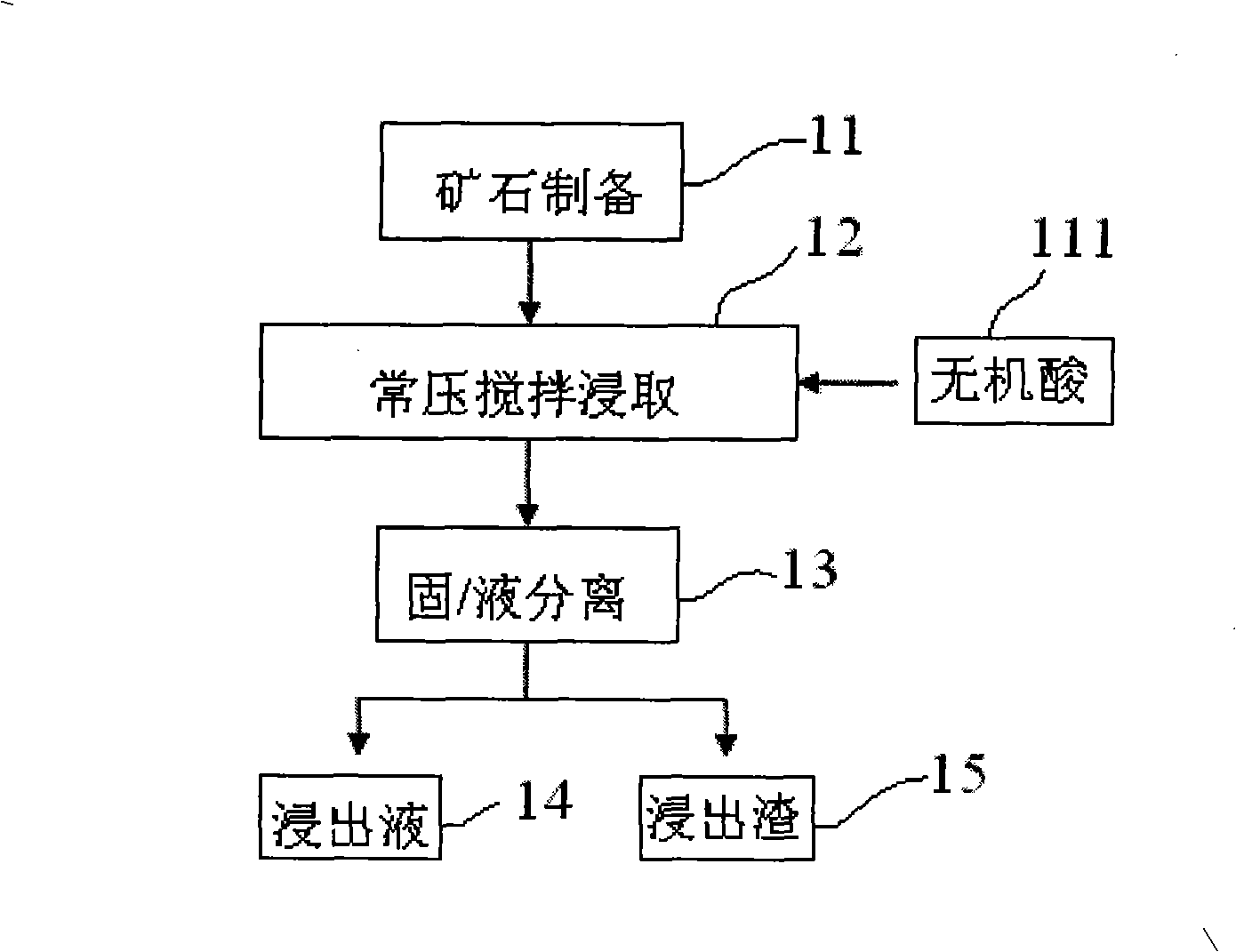

[0033] Such as figure 1 As shown, the normal-pressure stirring and leaching process flow for producing nickel-cobalt products from limonite-type ore comprises the following steps: ore preparation step 11, normal-pressure stirring and leaching step 12, and solid / liquid separation step 13, wherein the step The implementation of 12 includes the application step 111 of mineral acid, and the result of the solid / liquid separation step 13 is to produce a leaching solution 14 and a leaching residue 15 for producing nickel-cobalt products.

[0034] In an embodiment of the atmospheric pressure stirring and leaching process for producing nickel-cobalt products from limonite-type ore, the following steps are specifically included:

[0035] A. Crushing the ore with a particle size greater th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com