Ice and snow resistant, anti-corrosion paint and uses thereof

An anti-corrosion and coating technology, applied in anti-corrosion coatings, coatings, other chemical processes, etc., can solve problems such as power outages or information inaccessibility in areas, easy damage, collapse, etc., achieve low viscosity-temperature coefficient, prevent freezing, High anti-compression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A coating comprises the following raw materials in parts by weight:

[0026] 2CaCl 2 2H 2 O 2.35 parts

[0027] C 2 h 8 o 2 Si 1.45 parts

[0028] Na 2 HPO 4 12H 2 O 1.10 parts

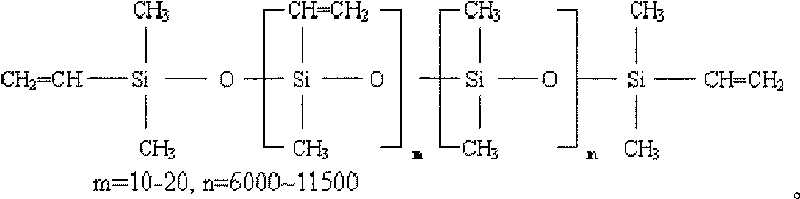

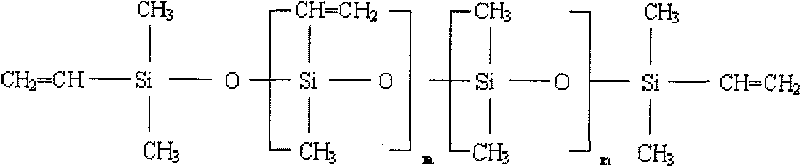

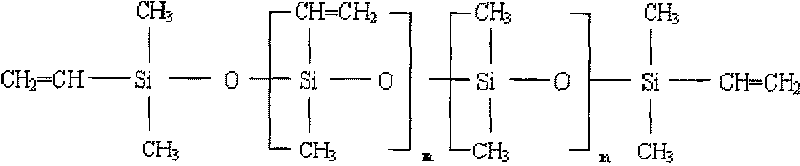

[0029] Methyl vinyl silicone rubber 1.30 parts

[0030] C 2 h 5 -O-[Si(OC 2 h 5 )(CH 3 )-O]-Si(CH 3 )(OC 2 h 5 ) 2 1.48 servings.

Embodiment 2

[0032] Another kind of coating comprises the following raw materials in parts by weight:

[0033] CaCl 2 2.15 servings

[0034] ZBH-255 type phenylmethyl silicone oil 1.20 parts

[0035] C 2 h 5 -O-[Si(OC 2 h 5 )(CH 3 )-O]-Si(CH 3 )(OC 2 h 5 ) 2 0.95 servings

[0036] Na 2 HPO 4 12H 2 O 0.82 parts

[0037] Methyl vinyl silicone rubber 1.15 parts

[0038] CHCHCOOH 0.75 parts.

[0039] Among them: ZBH-255 type phenylmethyl silicone oil is commercially available and produced by Qingdao Zhongbao Chemical Co., Ltd.

Embodiment 3

[0041] The third kind of coating comprises the following raw materials in parts by weight:

[0042] CaCl 2 2.25 servings

[0043] C 2 h 5 -O-[Si(OC 2 h 5 )(CH 3 )-O]-Si(CH 3 )(OC 2 h 5 ) 2 1.0 copies

[0044] Na 2 HPO 4 12H 2 O 1.0 parts

[0045] Methyl vinyl silicone rubber 1.25 parts

[0046] (CH 3 ) 3 SiO[(CH 3 )] 2 SiO]N-Si(CH 3 ) 3 1.25 servings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com