Method for preparing polyalcohol-base light overpressure resistant floating force material and equipment thereof

A technology of buoyancy materials and polymers, applied in the field of lightweight materials, can solve problems such as poor performance, difficult to remove, and large air bubble content, and achieve the effects of stable performance, low water absorption, and high elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 (mixed material viscosity value is 10000~100000cps):

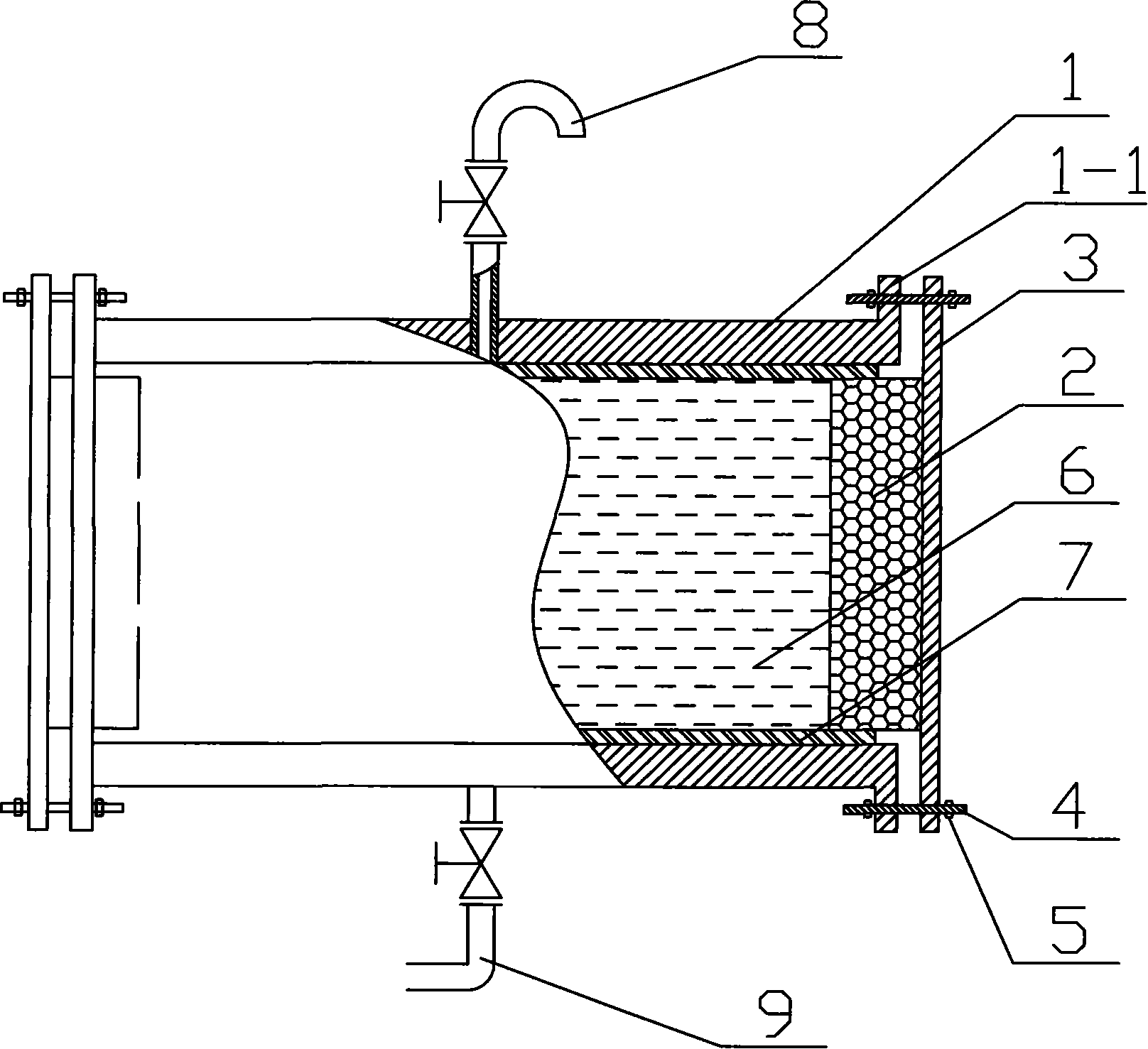

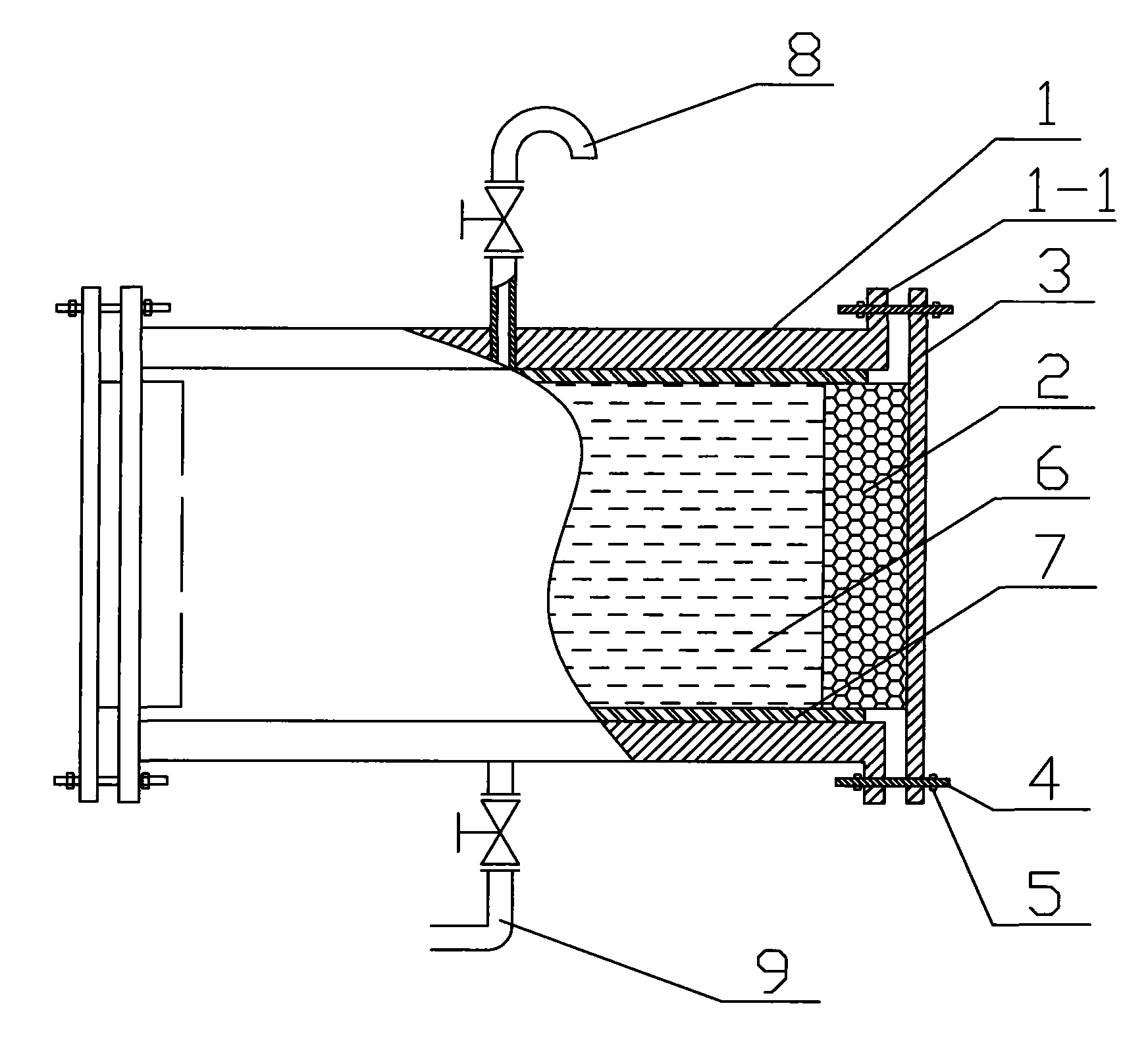

[0046] Add 100 parts of bisphenol A liquid epoxy resin E~51, 75 parts of methyltetrahydrophthalic anhydride MeTHPA, 0.2 parts of silane coupling agent KH~550, and 0.5 parts of wetting and dispersing agent into the container, and use high Stir with a constant speed mixer with shear force, such as a dough mixer or a planetary mixer. After stirring evenly, add 50 parts of glass hollow microspheres. After stirring well, add 40 parts of glass hollow microspheres in batches and stir evenly. Use the feeding method 1 to pump the mixed material through the material inlet 9 through the pressure pump figure 1 In the devices shown, the retaining nuts on the devices are determined to be at maximum slack. Seal the material inlet 9 and the air outlet 8, and then tighten the fastening nuts 10 evenly.

[0047] Put the mixed material together with the equipment into the oven for heating and curing. The curing process i...

Embodiment 2

[0051] Embodiment 2 (when the viscosity value of the mixed material is 100000~250000cps):

[0052] Heat 100 parts of bisphenol A liquid epoxy resin E~51 to 75~80°C, add 0.2 parts of silane coupling agent and 0.5 parts of wetting and dispersing agent and stir evenly; add 80 parts of glass hollow microspheres into the resin in batches , Stir evenly with a high-shear constant-speed stirrer; heat 30 parts of aromatic amine curing agent diaminodiphenylmethane to 85-90°C, and after the solid diaminodiphenylmethane is completely melted, quickly add it to the previous mixing In the good material, stir evenly. Close the material inlet and air outlet, and add the mixed material into the figure 1 in the device shown. Specifically: open the fixing bolts, remove the pressure metal cover and pressure adjustment layer, fill the material into the equipment, install the pressure adjustment layer after filling, cover the pressure metal cover, screw on the bolts, and then put the nuts evenly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com