Process for manufacturing steel spoke

A manufacturing process and wheel spoke technology, applied in the field of steel spoke manufacturing process, can solve problems such as low material utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing.

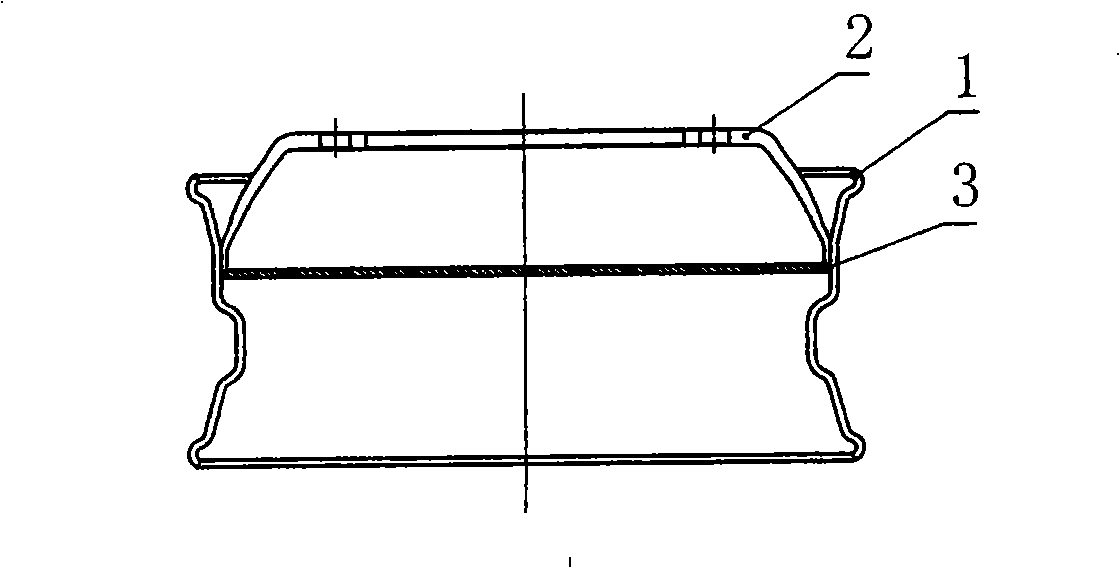

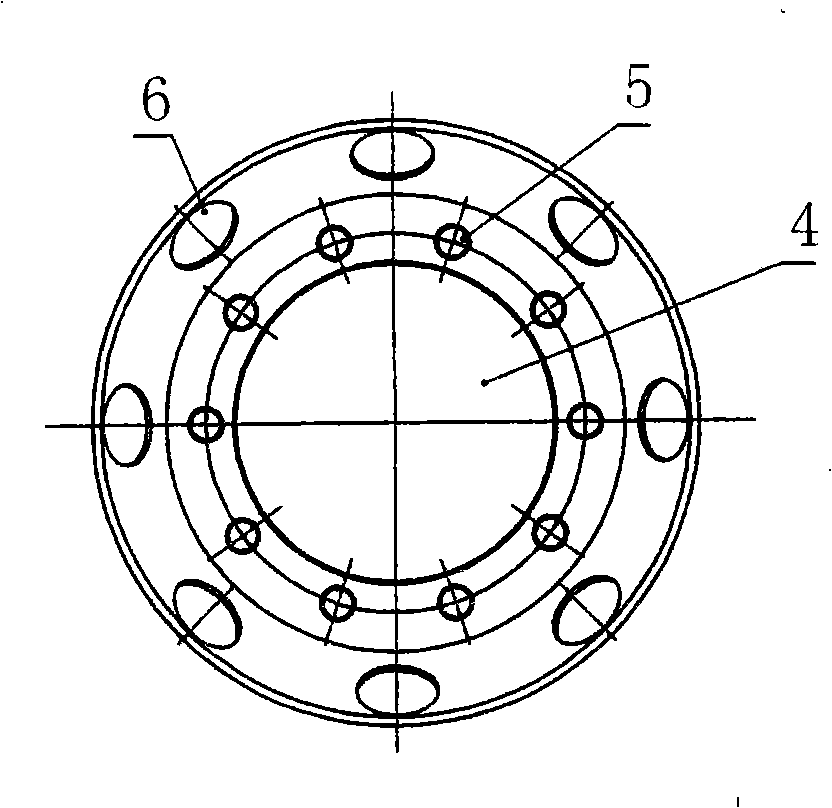

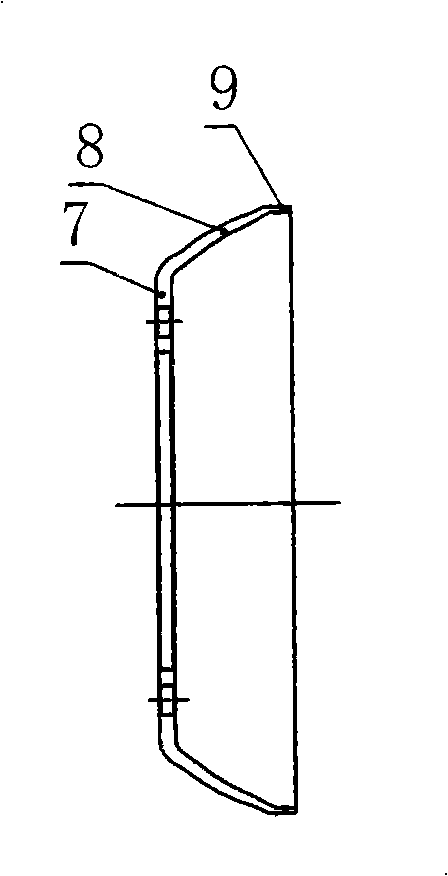

[0012] Such as figure 1 As shown, the tubeless steel wheel generally consists of two parts, a rim 1 and a spoke 2, which are manufactured separately, and then combined and welded together, and 3 is a weld. Such as figure 2 with image 3 As shown, the spokes include a mounting plane 7 , a transition curve segment 8 and a straight line segment 9 , a central hole 4 and a bolt hole 5 are processed on the mounting plane 7 , and an air hole 6 is processed on the transition curve segment 8 . As shown in Figure 4, the traditional manufacturing process steps of spokes are: (A) steel plate blanking, (B) spinning, (C) punching center hole / bolt hole, (D) blasting hole, (E) leveling installation Plane, (F) Turning center hole / installation plane / outer circle / end face, (G) embossing.

[0013] As shown in Figure 5, the wheel spoke manufacturing process of the present invention is to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com