Calcium sulphate composite bone renovation material, preparation method and application thereof

A composite material, calcium sulfate technology, applied in the direction of bone implants, medical science, prosthesis, etc., can solve the problems of clinical application limitations, adverse effects of other system functions, etc., achieve good physical and chemical properties, simple preparation method, good The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 The preparation of calcium sulfate composite material of the present invention

[0031] 1. Preparation of powder

[0032] Take α-calcium sulfate hemihydrate (α-CSH), strontium chloride (SrCl 2 ), were mixed according to the lower molar ratio shown in Table 1 (the same below), were ground and mixed evenly in a mortar, passed through a 400 mesh sieve, dried for later use, and all reagents used were of analytical grade.

[0033] The formula of various calcium sulfate composite materials of table 1

[0034]

[0035] 2. Preparation of solidification solution

[0036] Determine the liquid-solid ratio: The liquid-solid ratio will directly affect the setting time and the mechanical properties of the material. Therefore, before determining the coagulation time and compressive strength of strontium-doped calcium sulfate, the optimum liquid-solid ratio was determined first. The principle is: the minimum liquid-solid ratio when the powder material is completely ...

Embodiment 2

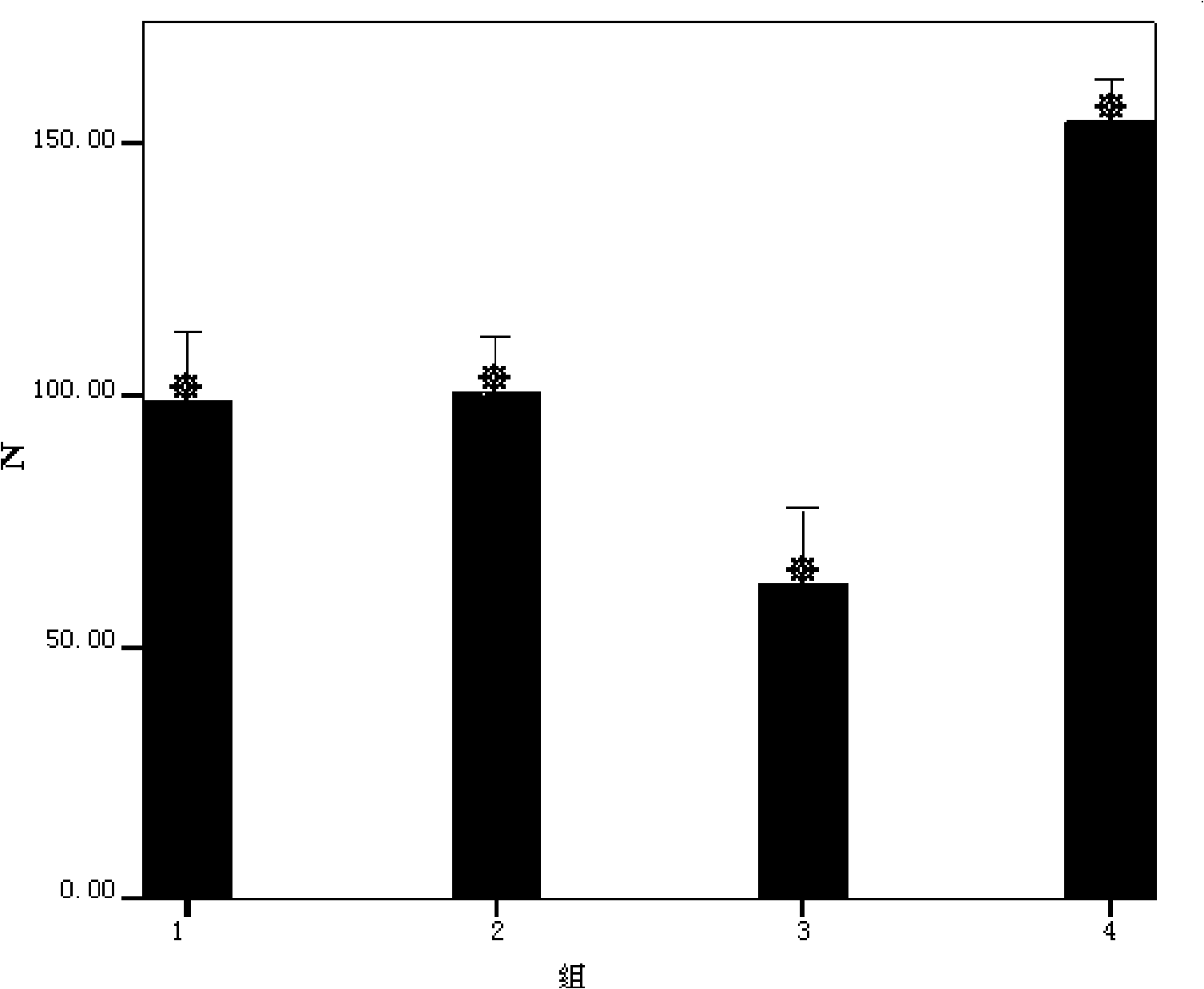

[0058] Example 2 In vivo histocompatibility experiment of calcium sulfate composite material of the present invention

[0059] The histocompatibility of biomaterials is an important issue to be considered first in the research of biomedical materials. Histocompatibility refers to the performance of biomaterials that are accepted by human tissues after a series of interactions occur at the material-tissue interface after they are in contact with human tissues. Intramuscular implantation experiment to observe the histological changes caused by materials implanted in vivo is the main system for evaluating histocompatibility at present. Intracellular enzymes control the life activities of cells. When stimulated by external factors, the changes of corresponding enzyme activities are earlier and more sensitive than the changes of cell morphology. Previous examples have proved that strontium-doped calcium sulfate with a strontium-doped amount of 0.5% has the best in vitro physical, ...

Embodiment 4

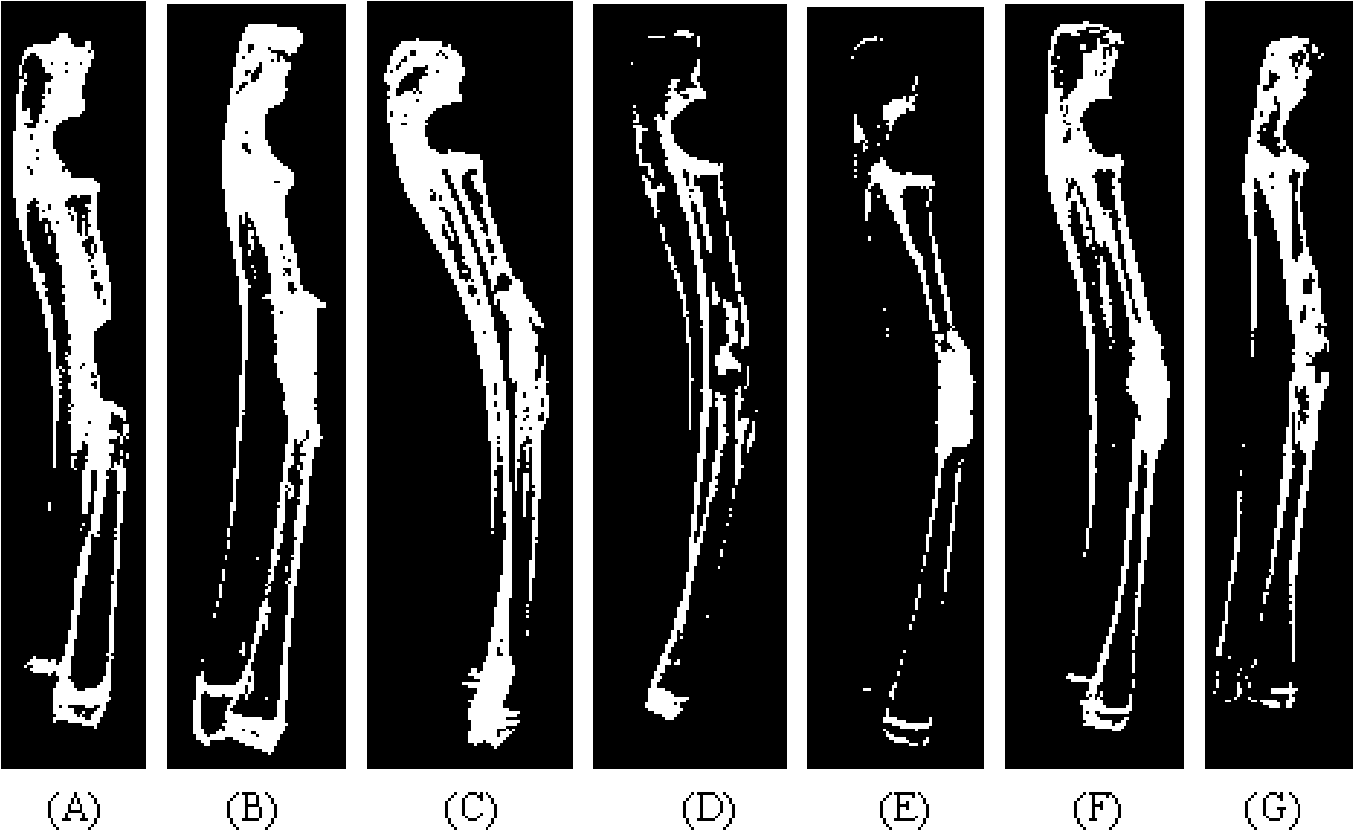

[0091] Embodiment 4 Using the calcium sulfate composite material of the present invention to repair bone defects

[0092] Clinically, trauma, infection, tumor and many other injuries can lead to bone structural defects. When the bone defect range exceeds the limit of bone self-repair ability or the bone tissue function is lost due to lesions, it is necessary to go through surgical methods and rely on Biomaterials are used to repair bone defects or replace diseased tissues, that is, to use bone grafts to fill defects and eliminate dead space, so as to restore the morphology, mechanical strength and anatomical function of the lesion. In order to further verify whether the strontium-doped calcium sulfate composite material of the present invention can be used as a good bone repair biomaterial, the present embodiment will use the strontium-doped calcium sulfate composite material as a bone repair material to carry out segmental bone defect of rabbit radius and rabbit femur Condyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com