Dispersing agent for aluminum titanium boron production and preparation method thereof

A technology of dispersing agent and aluminum-titanium-boron, which is applied in the field of dispersing agent for aluminum-titanium-boron production and its preparation, can solve problems such as uneven distribution of tissue, and achieve the effects of excellent and stable refining ability and quality improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

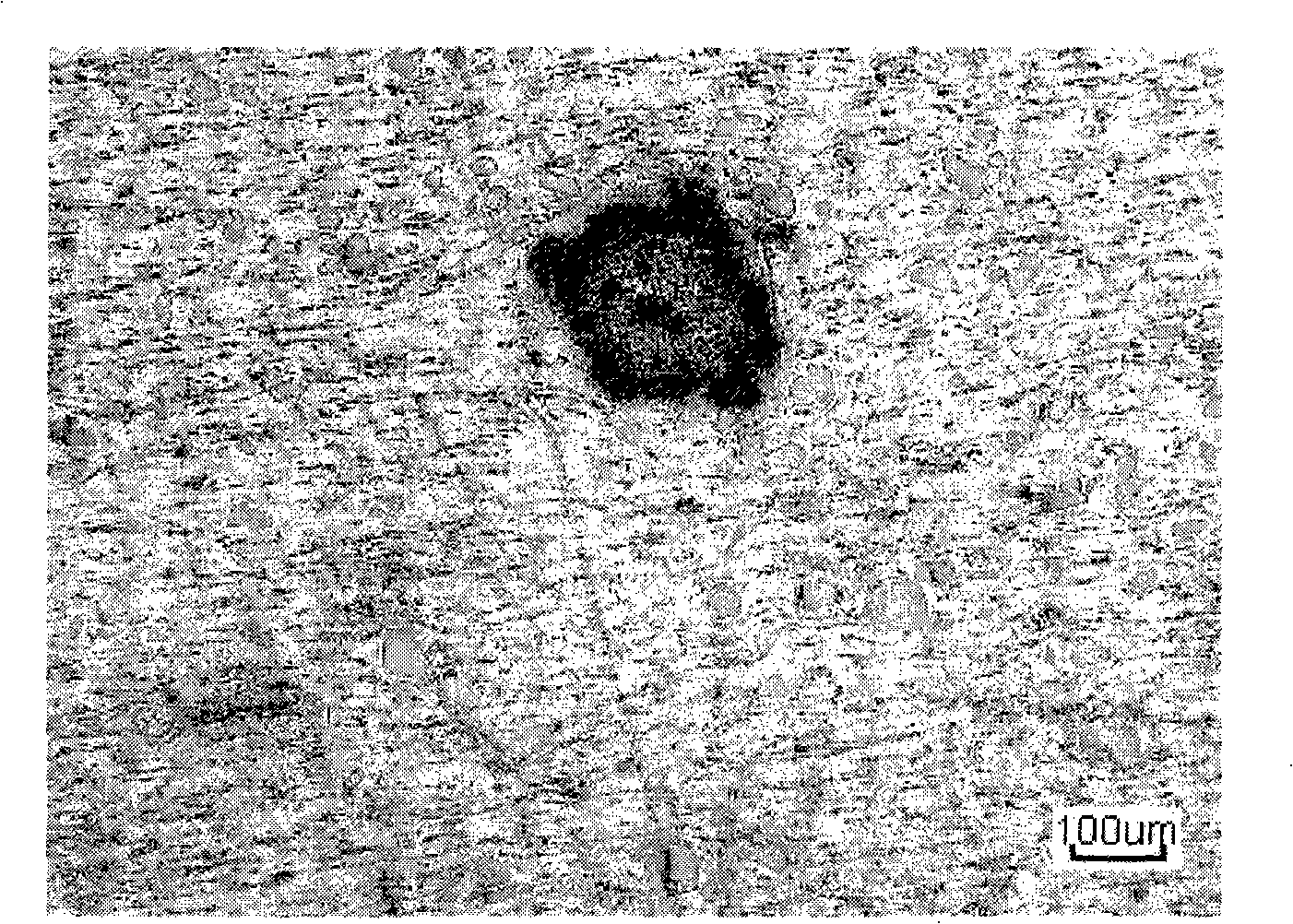

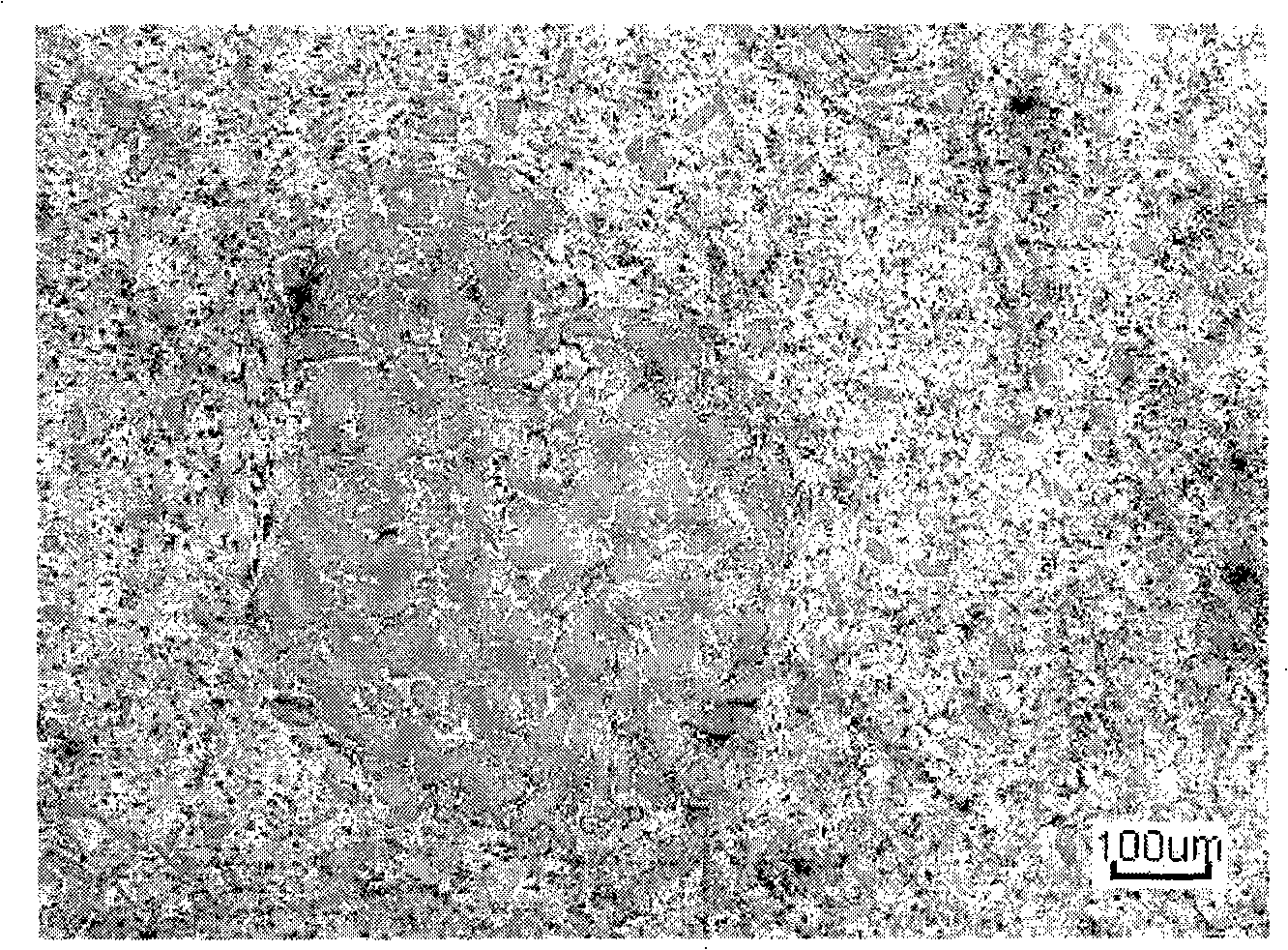

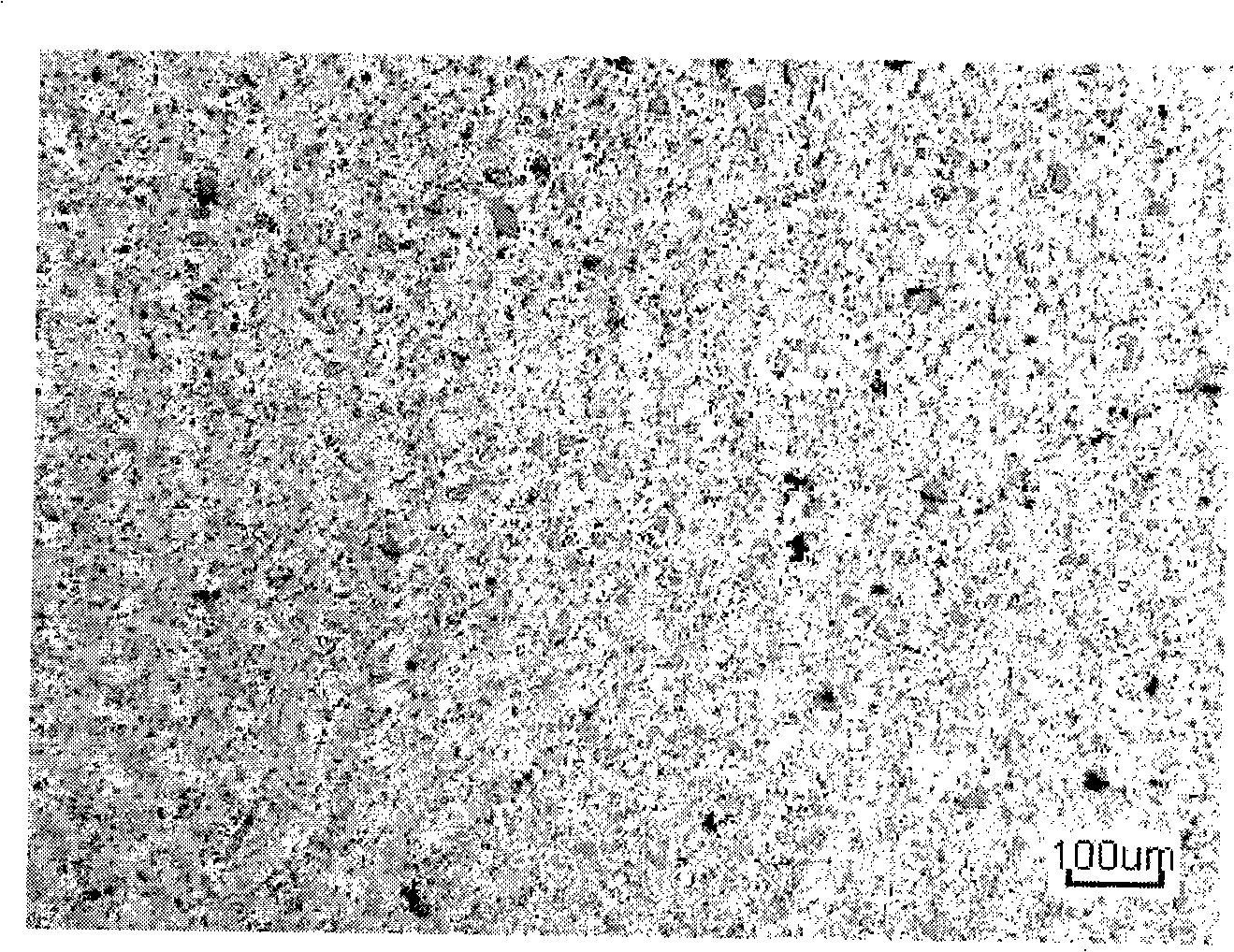

Image

Examples

Embodiment 1

[0025] Mix 35kg of sodium fluoroaluminate, 25kg of potassium chloride and 20kg of sodium chloride, add in the crucible furnace to heat up and melt, control the temperature of the solution at 700°C, stir for 10 minutes, then add 15kg of magnesium fluoride and 5kg of cerium chloride successively, Continue to stir for 3-5 minutes, then pour into a cast steel mold to cool, crush and pulverize into 80-mesh dispersant, bag and seal.

Embodiment 2

[0027] Mix 40kg of sodium fluoroaluminate, 25kg of potassium chloride and 15kg of sodium chloride, add in the crucible furnace to heat up and melt, control the temperature of the solution at 715°C, stir for 12 minutes, then add 16kg of magnesium fluoride and 4kg of cerium chloride successively, Continue stirring for 3-5 minutes, then pour into a cast steel mold to cool, crush and pulverize into a 140-mesh dispersant, bag and seal.

Embodiment 3

[0029] Mix 35kg of sodium fluoroaluminate, 25kg of potassium chloride and 22kg of sodium chloride, add in the crucible furnace to heat up and melt, control the temperature of the solution at 730°C, stir for 15 minutes, then add 15kg of magnesium fluoride and 3kg of cerium chloride successively, Continue stirring for 3-5 minutes, then pour into a cast steel mold to cool, crush and pulverize into a 200-mesh dispersant, bag and seal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com