Method for preparing high grade activated carbon from rice husk ash

A production method and technology of rice husk ash, applied in the field of co-production of water glass and activated carbon with rice husk ash, can solve the problems of no practical production application and high cost of raw materials, achieve the effect of safe and non-toxic production process, and overcome the problem of excessive ash content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

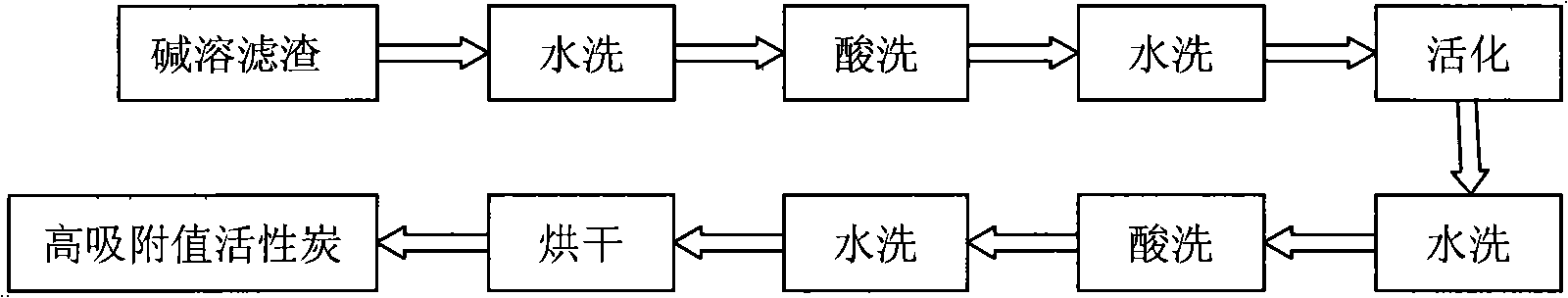

Image

Examples

Embodiment 1

[0019] Embodiment one: a kind of rice husk ash of the present invention produces the production method of high-quality activated carbon, adopts following process step: its component and proportioning are by weight:

[0020] The invention uses rice husk ash to prepare water glass as raw material (silicon dioxide content in the alkali-soluble filter residue is 40%-45%). Wash the alkali-soluble wet slag after preparing water glass from rice husk ash with hot water at 80°C to pH 10, and then use hydrochloric acid with a concentration of 0.5mol / L, according to the dosage of 6 parts of hydrochloric acid per 1 part of alkali-soluble filter residue. Acid washing, after pickling, the solid alkali-soluble filter residue is obtained; wash with 80°C hot water for the second time and wash to neutrality, and the alkali-soluble filter residue after washing should meet the following standards: carbon content is greater than 55%; methylene blue adsorption value is greater than 6mL / 0.1g; parti...

Embodiment 2

[0024] Embodiment two: a kind of rice husk ash of the present invention produces the production method of high-quality activated carbon, is characterized in that adopts following processing steps: its component and proportioning are by weight:

[0025] Wash the alkali-soluble wet slag after preparing water glass from rice husk ash with hot water at 85°C to pH 10, and then use hydrochloric acid with a concentration of 0.5mol / L, according to the amount of 7 parts of hydrochloric acid solution per 1 part of alkali-soluble filter residue. Pickling, washing the solid obtained after pickling with hot water at 85°C for a second time until neutral. Stir the alkali-soluble filter residue after the above-mentioned secondary water washing into potassium hydroxide to activate at high temperature. High-temperature activation: Dissolve 3.2 parts of potassium hydroxide in 5 parts of cold water, add 1 part of washed alkali-soluble filter residue immediately after it is completely dissolved, s...

Embodiment 3

[0026] Embodiment three: a kind of rice husk ash of the present invention produces the production method of high-quality activated carbon, is characterized in that adopts following processing step: its component and proportioning are by weight:

[0027] Wash the alkali-soluble wet slag after preparing water glass from rice husk ash with hot water at 90°C to pH 9, and then use hydrochloric acid with a concentration of 0.5mol / L to acidify according to the amount of 7 parts of hydrochloric acid required for every 1 part of alkali-soluble filter residue. Wash the solid obtained after acid washing with 90°C hot water for a second time and wash until neutral. Stir the alkali-soluble filter residue after the above-mentioned secondary water washing into potassium hydroxide to activate at high temperature. High-temperature activation: Dissolve 3.5 parts of potassium hydroxide in 5.5 parts of cold water, add 1 part of washed alkali-soluble filter residue immediately after it is complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com