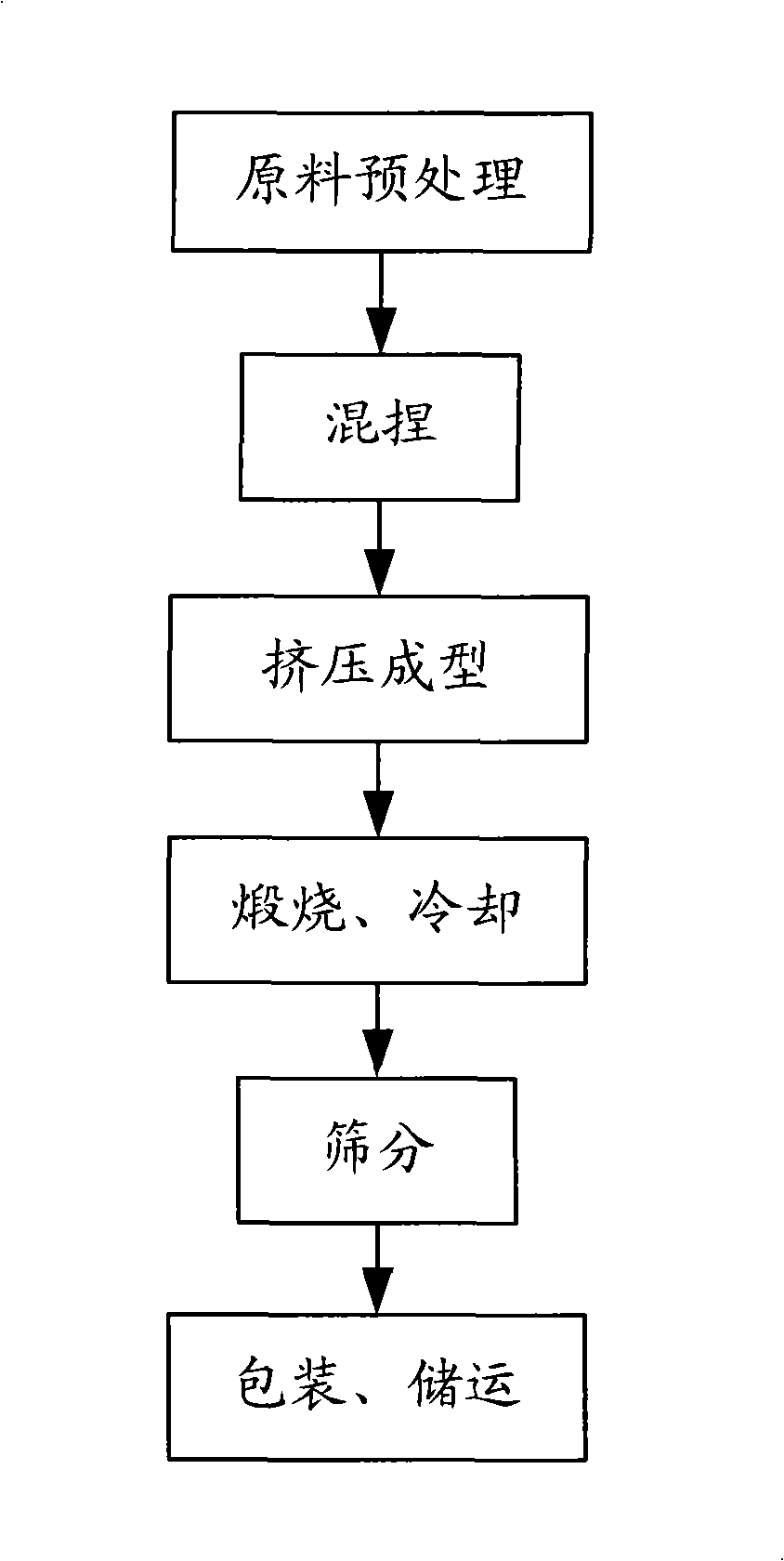

Method for producing calcined coke by pot type furnace

A technology of calcining coke and pot furnace, which is applied in coking ovens, coking carbonaceous materials, petroleum industry, etc. It can solve the problems of easy generation of large dust, small particle size of products, and difficulty in meeting industrial production, so as to avoid environmental pollution problems, Stabilization of thermal reactivity and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Raw material ratio: In terms of weight ratio, petroleum coke is 85%, and pitch is 15%.

[0035] The above-mentioned petroleum coke is pre-crushed to less than 10 mm, and the pitch is melted into a liquid state to facilitate its kneading and molding.

[0036] (2) Put the above-mentioned raw materials into a kneading pot and knead for 40 minutes to obtain a uniform paste.

[0037] (3) Transfer the above-mentioned paste to a molding machine, and produce a molded green body with a particle size of 30 mm through die extrusion.

[0038] (4) Sprinkle the petroleum coke powder protective material on the surface of the green body, wherein the ratio of the green body to the coke powder is 80% / 20% by weight. The green body and coke powder protective material are loaded into the top of the tank furnace through a hoist for calcination, the furnace temperature is controlled at about 1200 degrees, and the coke is slowly calcined for 60 hours.

[0039] (5) The finished calcined coke an...

Embodiment 2

[0050] (1) Raw material ratio: In terms of weight ratio, petroleum coke is 75%, calcined coke is 10%, and pitch is 15%.

[0051] The above-mentioned petroleum coke and calcined coke are pre-crushed to less than 10mm; the pitch is melted into a liquid state.

[0052] (2) Put the above raw materials into a kneading pot and knead for 50 minutes to obtain a uniform paste.

[0053] (3) Transfer the above paste to a molding machine, and produce a molded green body with a particle size of 50 mm through die extrusion.

[0054] (4) Sprinkle the petroleum coke powder protective material on the surface of the green body, wherein the ratio of the green body to the coke powder is 70% / 30% by weight. The green body and the coke powder protective material are loaded into the top of the tank furnace through a hoist for calcination, the furnace temperature is controlled at about 1250 degrees, and the coke is produced after 72 hours of slow calcination.

[0055] (5) The finished calcined coke and ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com