Preparation of edible mushroom seasoning base

A technology of seasoning base material and edible fungus, which is applied in the field of preparation of edible fungus seasoning base material, to achieve the effects of promoting development, improving technological content and added value, and increasing varieties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

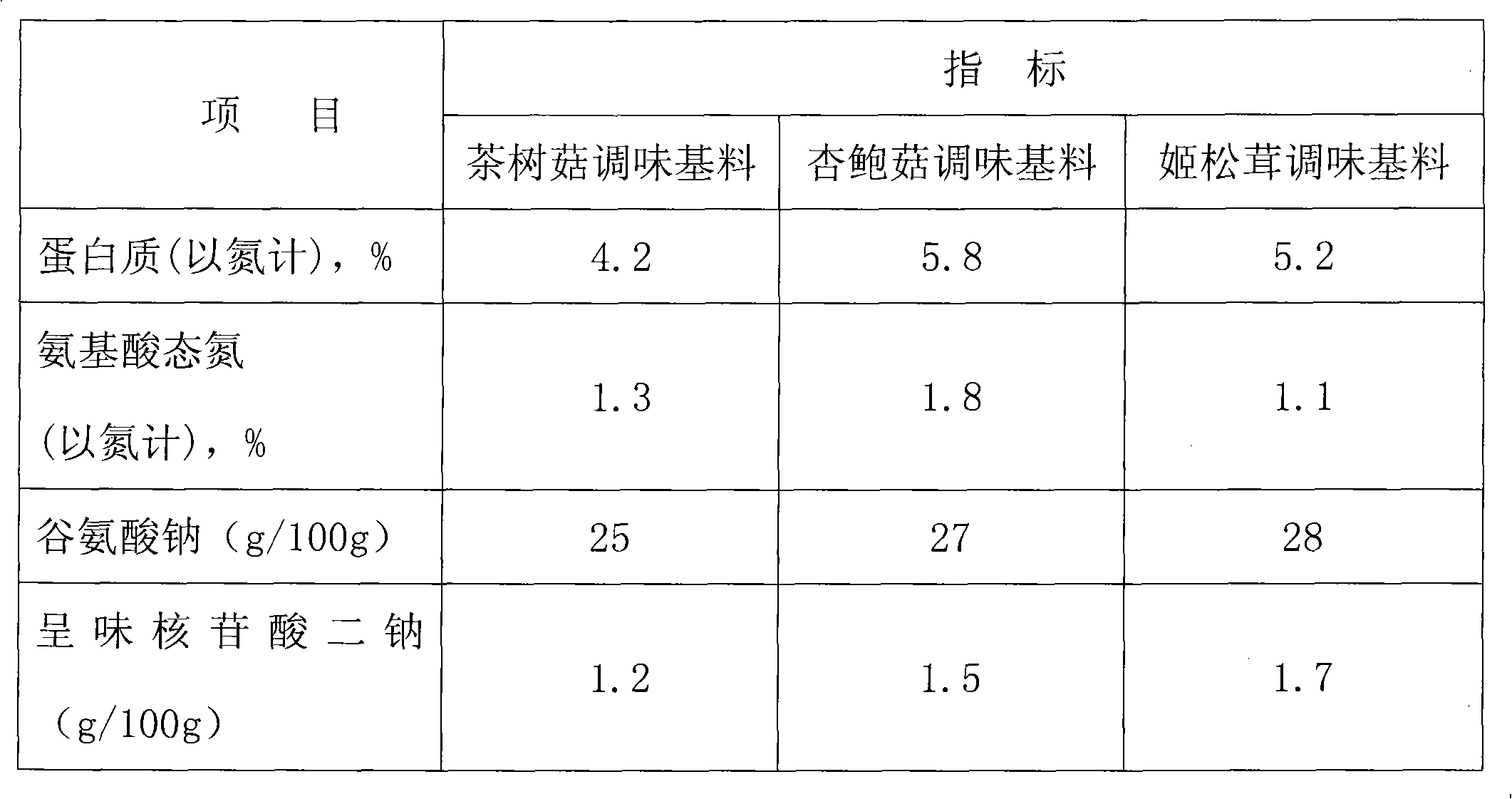

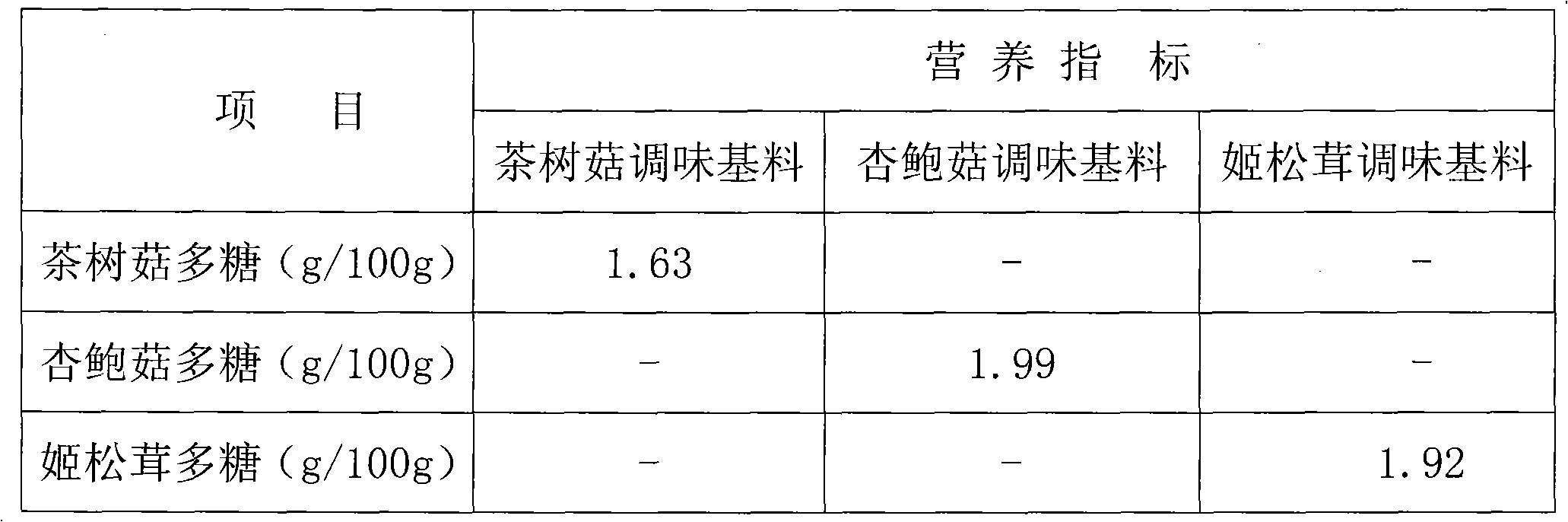

[0027] Embodiment 1: the preparation of tea tree mushroom seasoning base material

[0028] (1) Get 400 grams of dried Agrocybe sieve, pulverize to cross 20 mesh sieves;

[0029] (2) Add 8000ml of water, pour it into a beater after boiling, beat for 5 minutes, adjust the pH to 9.5-10, and hydrolyze at 55°C for 6 hours;

[0030] (3) Adjust the pH value of the hydrolyzed pulp to 8, then add 1 gram of flavor protease, and enzymolyze it at 61°C for 7 hours;

[0031] (4) Adjust the pH value of the enzymolysis pulp to 8, then add 200000U 5'-phosphodiesterase, and perform a second enzymolysis at 70°C for 3 hours, stir slowly during enzymolysis, then raise the temperature to 100°C and keep a constant temperature 10 minutes to kill the enzyme;

[0032] (5) Filtrate the secondary enzymatic hydrolysis slurry, and concentrate the filtrate to 10Bx in vacuum to obtain 2000ml concentrated slurry;

[0033] (6) Add methionine 10g, cysteine 4g, glucose 60g, sucrose 60g, monosodium glutamate...

Embodiment 2

[0035] Embodiment 2: the preparation of Pleurotus eryngii seasoning base material

[0036] (1) Get 1000 grams of dry Pleurotus eryngii, crush to cross 60 mesh sieves;

[0037] (2) Add 15000ml of water, pour it into a beater after boiling, beat for 5 minutes, adjust the pH to 10, and hydrolyze at 55°C for 6 hours;

[0038] (3) Adjust the pH value of the hydrolyzed pulp to 7, then add 3 grams of flavor protease, and enzymolyze it at 60°C for 7 hours;

[0039] (4) Adjust the pH value of the enzymolysis pulp to 7, then add 350000U 5'-phosphodiesterase, perform a second enzymolysis at 70°C for 2 hours, stir slowly during the enzymolysis, then raise the temperature to 100°C and keep the temperature constant 10 minutes to kill the enzyme;

[0040] (5) Filtrate the secondary enzymatic hydrolysis slurry, and concentrate the filtrate to 15Bx in vacuum to obtain 3500ml concentrated slurry;

[0041] (6) Add methionine 10g, cysteine 12.5g, glucose 175g, sucrose 280g, monosodium glutam...

Embodiment 3

[0043] Embodiment 3: the preparation of agaricus blazei seasoning base material

[0044] (1) Get 500 grams of dried Agaricus blazei and grind it to a 60-mesh sieve;

[0045] (2) Add 10000ml of water, pour it into a beater after boiling, beat for 5 minutes, adjust the pH to 9, and hydrolyze at 60°C for 2 hours;

[0046] (3) Adjust the pH value of the hydrolyzed pulp to 7, then add 1.2 grams of flavor protease, and enzymolyze it at 62°C for 7 hours;

[0047] (4) Adjust the pH value of the enzymolysis pulp to 7.5, then add 250000U 5'-phosphodiesterase, and perform a second enzymolysis at 70°C for 3 hours, stir slowly during enzymolysis, then raise the temperature to 100°C and maintain a constant temperature 10 minutes to kill the enzyme;

[0048] (5) Filtrate the secondary enzymatic slurry, and concentrate the filtrate to 20Bx in vacuum to obtain 1250ml concentrated slurry;

[0049](6) Add 2.5 grams of methionine, 1.25 grams of cysteine, 37.5 grams of glucose, 75 grams of sucr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com