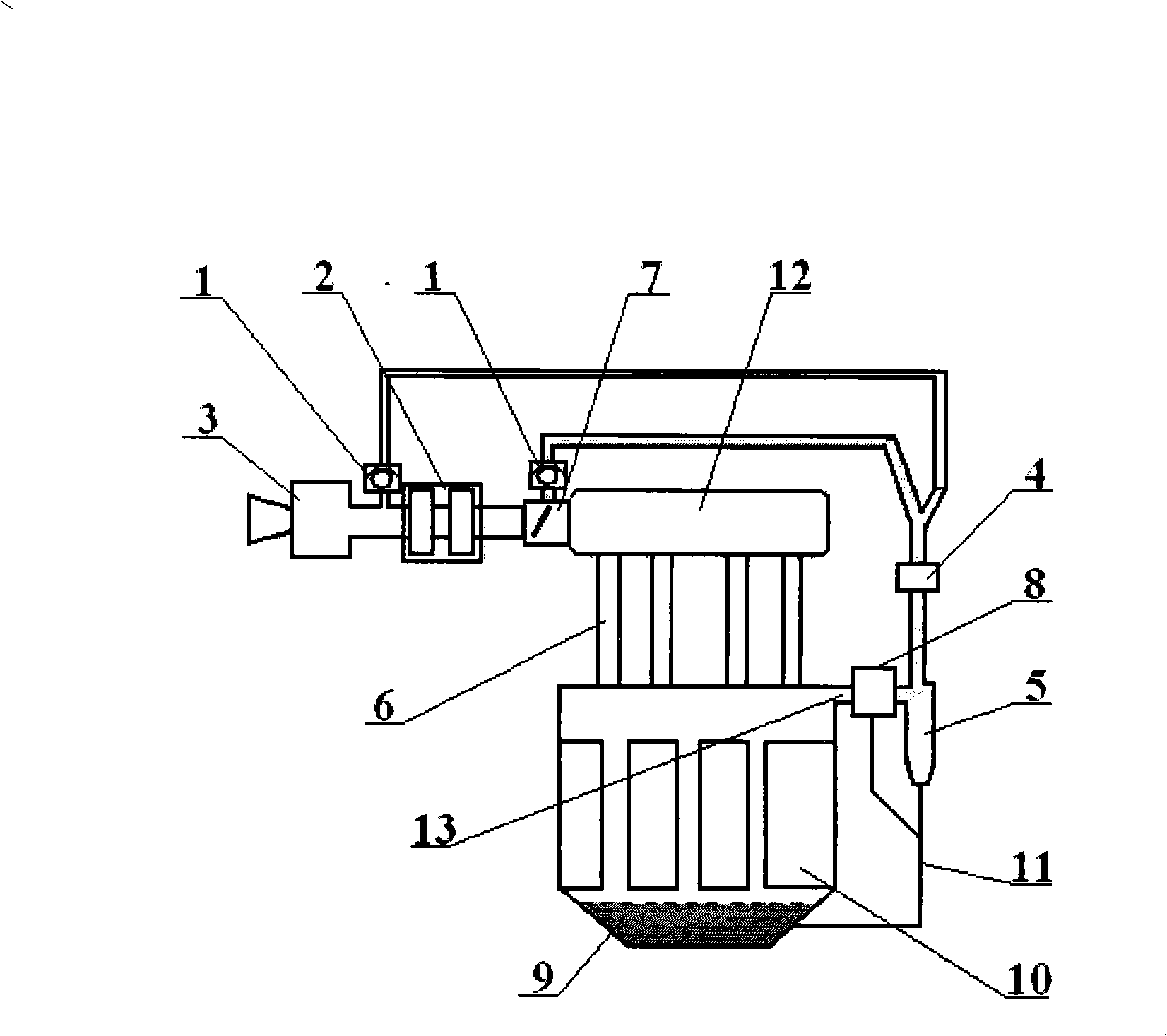

Engine crankcase oil gas separation system and its oil gas separation method

A separation system and oil-gas separator technology, applied in the field of automobile construction, can solve the problems of carbon deposition in the combustion system, poor oil-gas separation effect, poor oil-gas separation effect, etc., and achieve the effect of increasing the liquid content and improving the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Described intercooler 8 is provided with oil return pipe 11, and this oil return pipe 11 communicates with the oil return pipe 11 of oil-gas separator 5 below intercooler, and leads into the oil sump of engine.

[0036] There is an oil return pipe 11 in the intercooler 8, and the oil gas cooled in the intercooler 8 returns to the crankcase through the oil return pipe 11.

[0037] According to the matching situation of the actual engine and the vehicle, the intercooler can be air-cooled or water-cooled. According to actual conditions, the intercooler 8 can be water-cooled or air-cooled. The following are specific examples of these two methods, and one application can be selected;

Embodiment 2

[0039] The cooling method of the intercooler 8 is a fan cooling type, that is, a cooling fan is arranged outside the shell of the intercooler 8, and the intercooler 8 is cooled by blowing or sucking air.

[0040] The fan cooling method has a relatively simple structure. It only needs to use a motor to drive the fan to rotate to cool down, but its cooling effect is not as good as that of the water cooling method. The fan is arranged in the direction of the air inlet, which is a blowing cooling method; the fan is arranged in the opposite direction of the air inlet, which is a suction cooling method.

Embodiment 3

[0042] The cooling method of the intercooler 8 is a cooling water cooling method, that is, inside the housing of the intercooler 8, a pipeline for cooling water is provided, and the cooling water therein circulates through an independently provided cooling system; The cooling system shared by the engines circulates.

[0043] The above-mentioned structure is relatively complicated, requiring the use of water pumps, pipelines, water tanks and various valves, and frequent replenishment of cooling water. But its cooling effect is very good. Because the cooling water pipeline can go deep into the inside of the intercooler 8 to take away its heat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com