Speed matching control device between continuous tube apparatus infusion head and drum

A control device and speed matching technology, applied in the field of coiled tubing, can solve the problems that it is difficult to match the speed of the injection head and the drum, and the back tension of the drum cannot be obtained.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

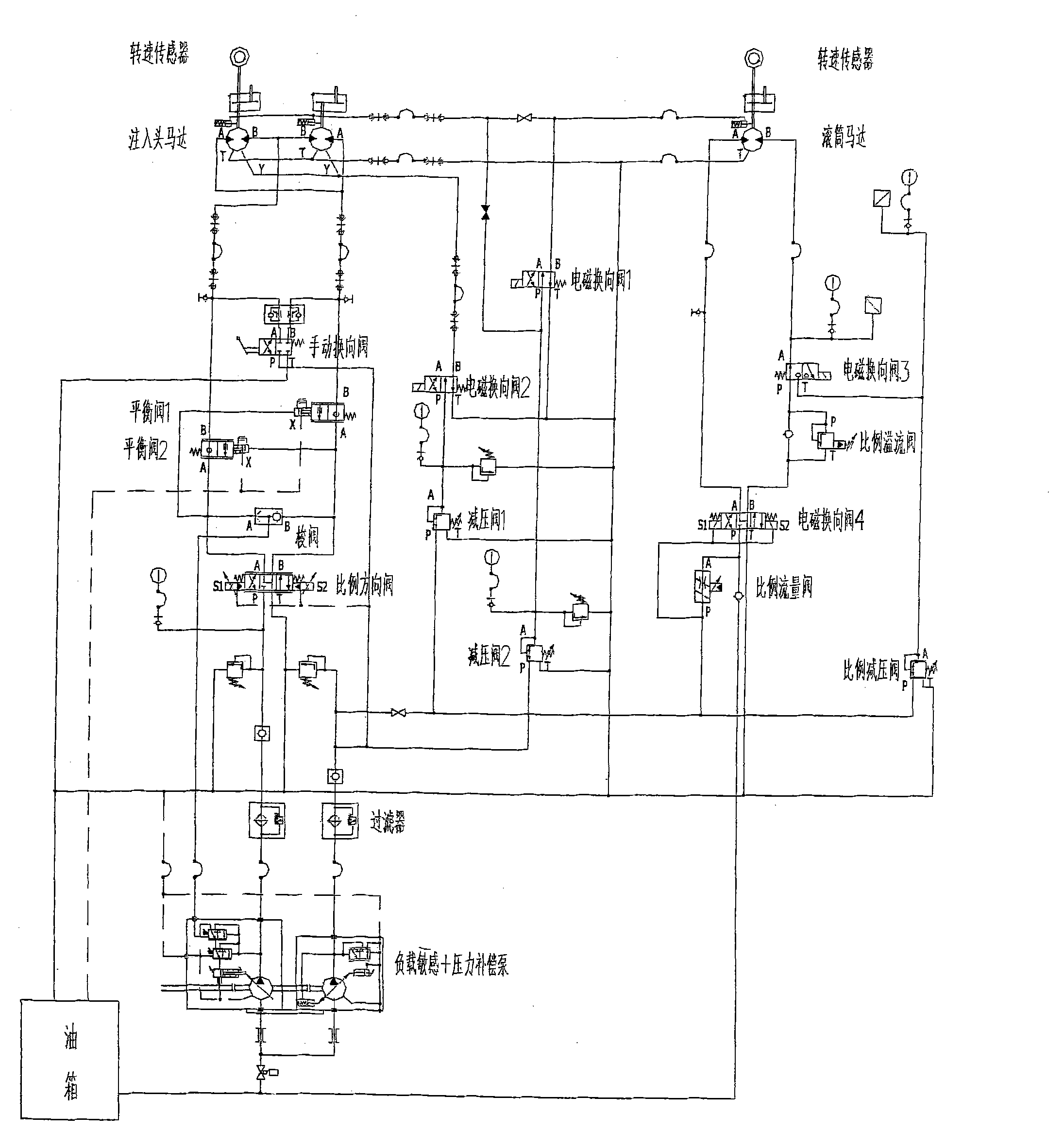

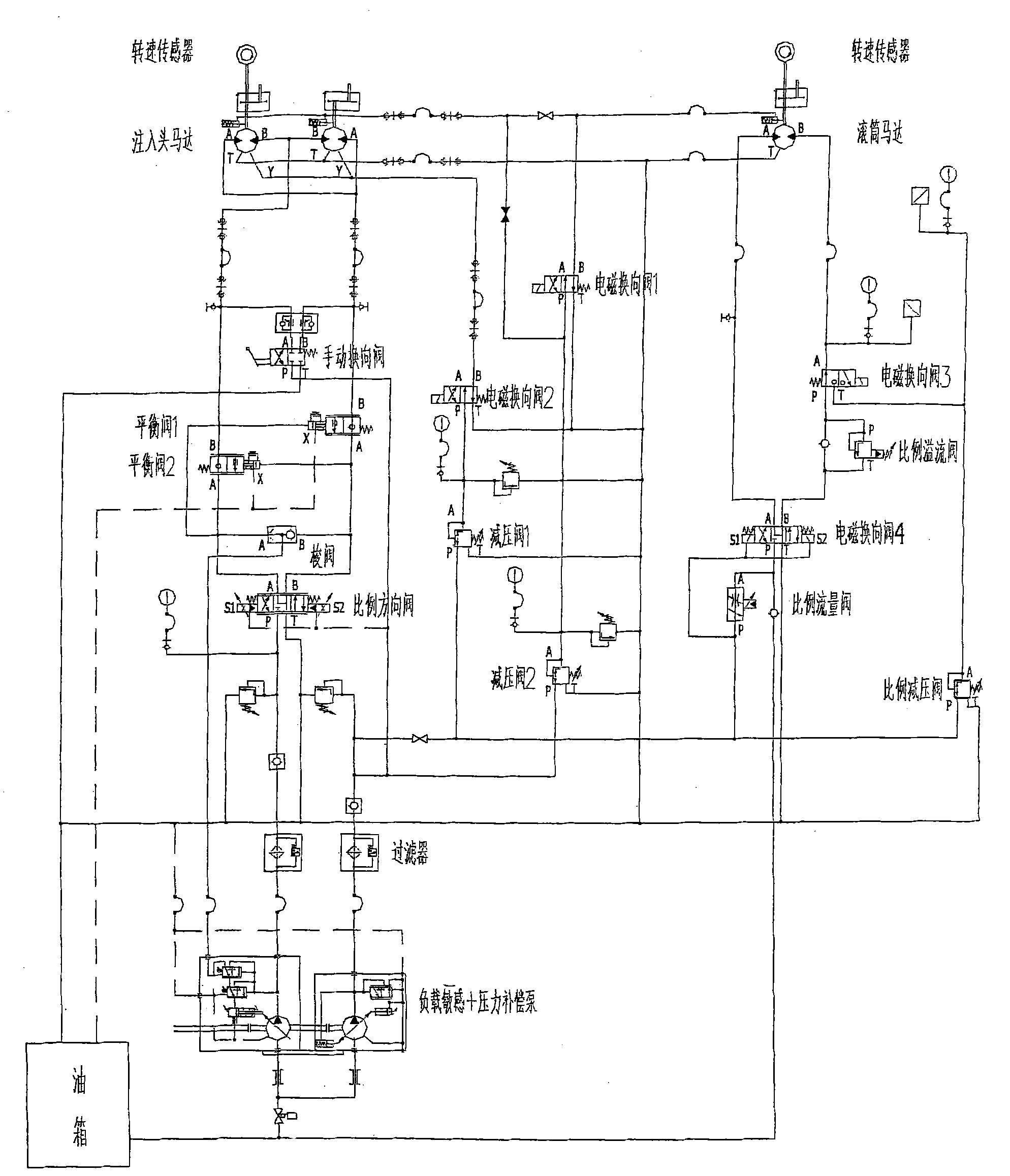

[0028] Embodiment 1: see attached figure 1 . The speed matching control device between the coiled tubing injection head and the drum of the present invention, the main components include: the model of the load sensitive pump is FRRO74BLS27. The model used for the pressure compensation pump is LRRO25CPC20. The model of proportional directional valve is DPZA-A-173. One shuttle valve model number is BGY2-220. The model of the two balancing valves is CINDY-12-B. A manual directional valve model is AH4Z61a / f. The model number of the two injection head motors is R20U+BD2-500 / 250 9HU+D40J. A drum motor model is GM1+F10+R13. The two pressure reducing valves are model MVSPM22-63. The two speed sensors are model GWM-40. The four solenoid directional valves are model DPHA-2713. A proportional relief valve model number is BVCPM22-200. A proportional pressure reducing valve model number is MVCPM22-200. A proportional flow valve model is QVHZA-A-06.

[0029] refer to figure 1 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com