Ultra-thin copper foil board water-base stamping stretching oil and producing method thereof

A technology of stamping, stretching and ultra-thin copper foil, which is applied in the petroleum industry, additives, lubricating compositions, etc. It can solve the problem that the surface of the workpiece cannot be directly assembled and used, and the cycle-type continuous operation cannot be realized, and the anti-rust and discoloration period of the workpiece surface is short. and other problems, to achieve the effect of excellent cooling performance, not easy to deteriorate, and no pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] a. Get raw material components, each raw material accounts for the percentage of total weight as follows:

[0042] Phytic acid 0.6-1.0%, sodium benzoate 1.6-1.8%, triethanolamine 2.2-2.6%, benzotriazole 0.08-0.12%, industrial ethanol 0.8-1.2%, Swire oil 4.8-5.2%, polyoxyethylene alkyl Ether 2.8-3.2%, polyethylene glycol 2.8-3.2%, glycerol 3.6-4.0%, deionized water 77-81%, isothiazolinone 0.1-0.2%.

[0043] Each raw material can be selected arbitrarily within the listed value range, and the total value should be 100%;

[0044] b. First dissolve the benzotriazole with the calculated amount of industrial alcohol, and set aside;

[0045] c. Add the calculated amount of deionized water, phytic acid, sodium benzoate, and triethanolamine into the reaction kettle in sequence, and then add the solution obtained in step a, start the agitator and stir at 360 rpm for 2 hours at room temperature ;

[0046] d. Add swire oil, polyoxyethylene alkyl ether, polyethylene glycol, glycer...

Embodiment 2

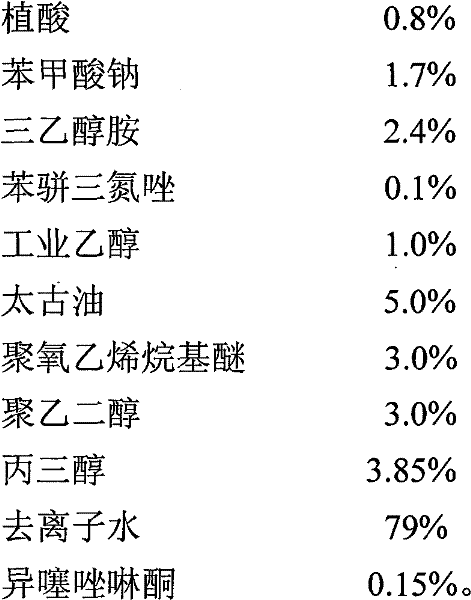

[0050] Raw material and production method are with embodiment 1, just the percentage of each raw material gross weight is as follows:

[0051] Phytic acid 0.8%, sodium benzoate 1.7%, triethanolamine 2.4%, benzotriazole 0.1%, industrial ethanol 1.0%, Swire oil 5.0%, polyoxyethylene alkyl ether 3.0%, polyethylene glycol 3.0%, propylene glycol Triol 3.85%, deionized water 79%, isothiazolinone 0.15%.

[0052] Appearance of the product is purple transparent liquid, pH value: 6.4~7.6. When in use, put the stock solution directly into the tank, and use it for pumping, circulating, spraying, stamping, stretching or artificial pouring on the surface of ultra-thin copper foil board. Conform to the technical requirements of the national standard (GB7631.5-89).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com