Two-stand angularly hot rolling minor diameter seamless steel tube rolling technique and equipment thereof

A seamless steel pipe, small diameter technology, applied in metal processing equipment, other manufacturing equipment/tools, metal rolling, etc., can solve problems such as rough inner wall, uneven outer diameter, inner diameter, wall thickness of steel pipe, and large investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

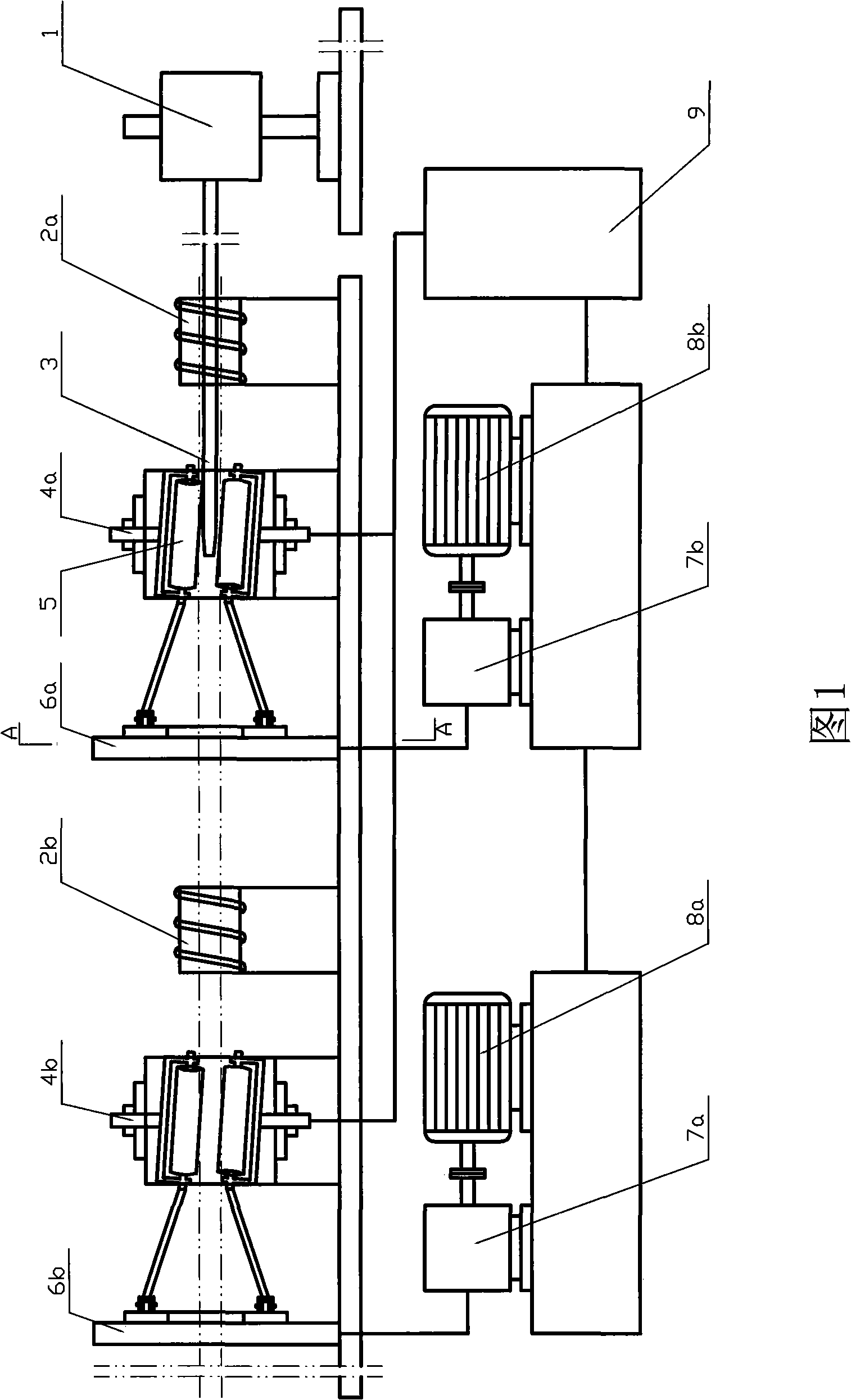

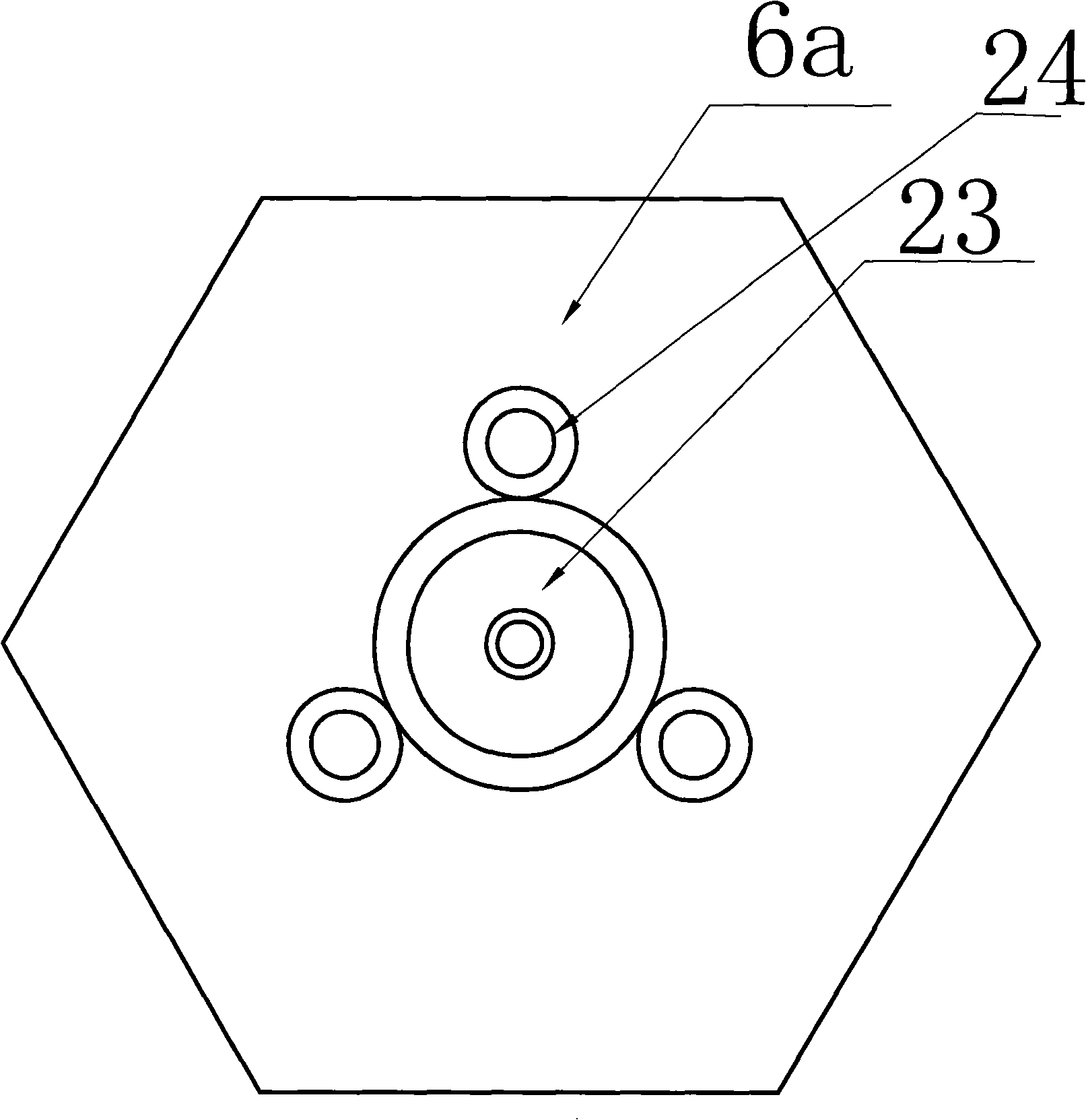

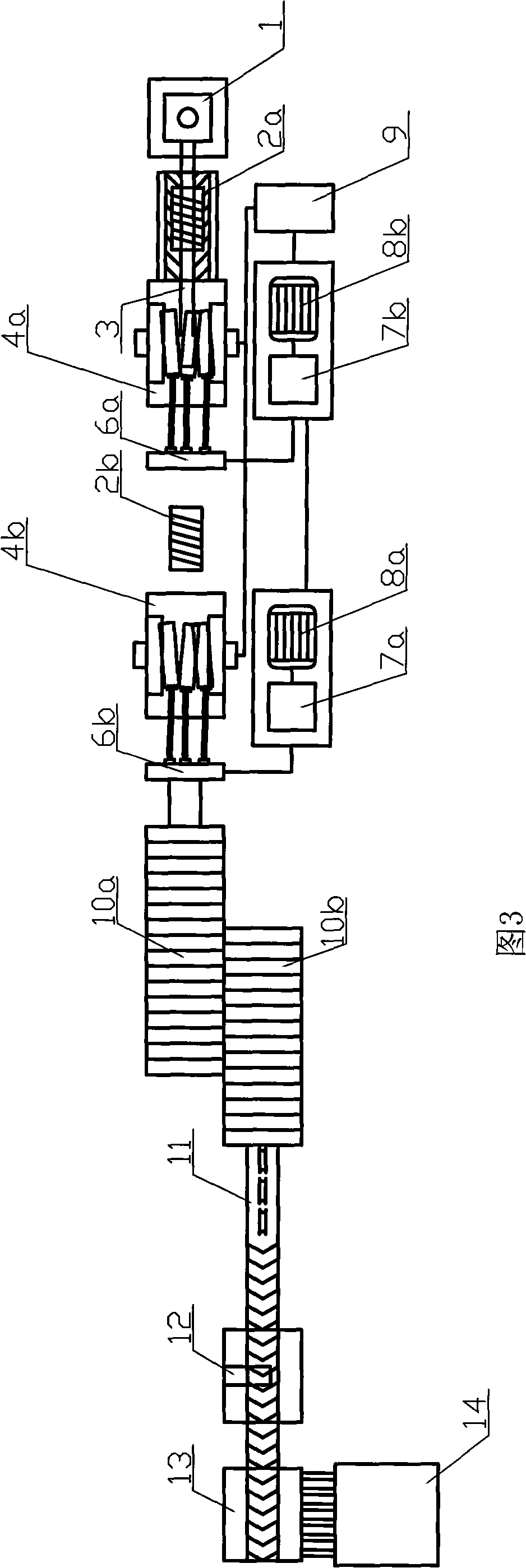

[0019] With reference to the drawings, the following examples of the present invention are given:

[0020] The production process of the embodiment of the present invention when rolling thick-walled and small-diameter seamless steel pipes is as follows: conveying roller table→mandrel penetration→mandrel trolley pushes waste pipe→induction heating→reduction and wall-increasing rolling with mandrel→ Cooling bed → straightening machine → finished product roller table → cutting machine → flaw detector → hydraulic testing machine → bundling. The mandrel trolley pushes the mandrel into the waste tube and pushes it forward. It is heated to 950~1150℃ by the medium-frequency induction heating electric furnace. The mandrel trolley continues to push the heated waste tube into the rolling mill for wall-increasing and diameter-reducing rolling. It is rolled while heating, and only the mandrel and roll are cooled during the rolling process. Since the distance from the heating furnace to the rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com