Sound insulating material

A sound insulation material and thermoplastic resin technology, applied in the field of sound insulation materials, can solve problems such as difficult cutting, large specific weight, and cracking of sound insulation sheets, and achieve the effects of not being easy to bend or warp, improving elongation, and good sound insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

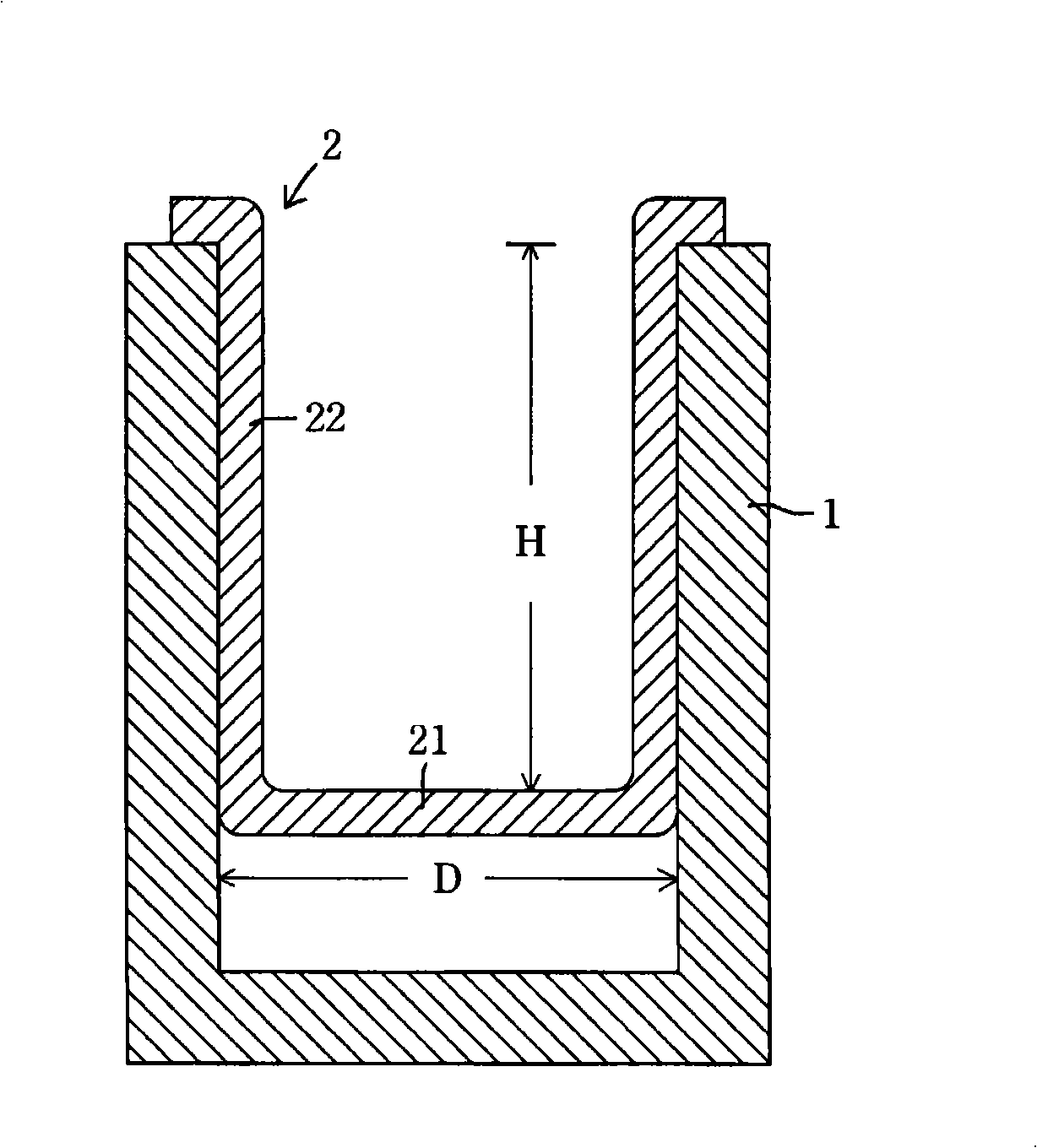

Image

Examples

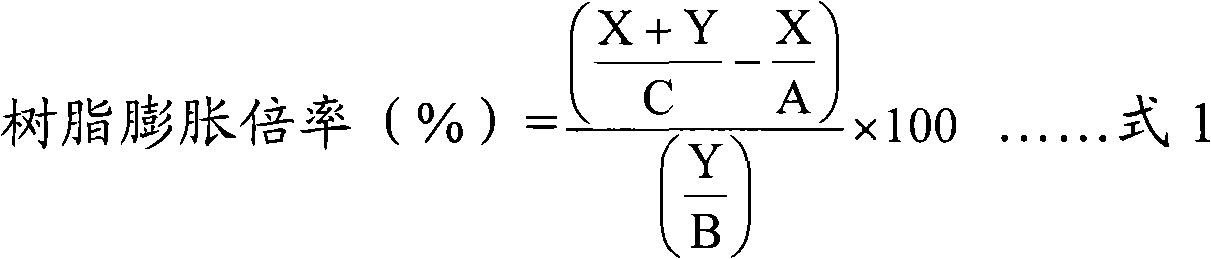

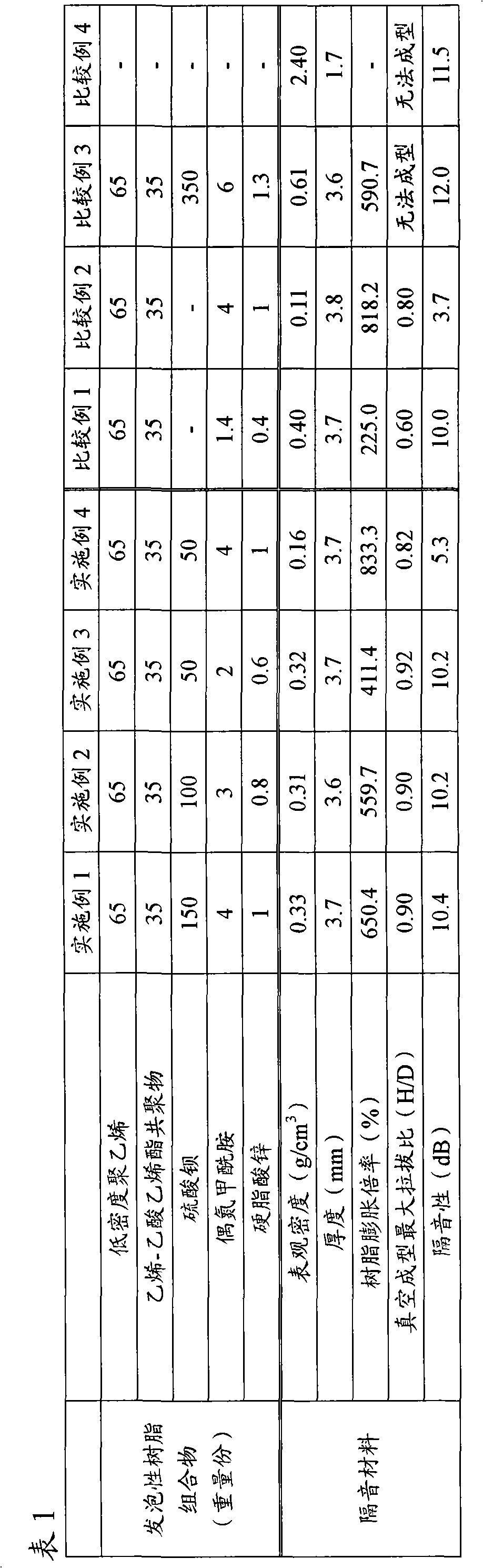

Embodiment 1

[0037] Knead the foamable resin composition at 110°C for 15 minutes using a test plastic mixer to make it evenly mixed, and then press mold the foamable resin composition at 110°C to prepare a foamable resin composition with a thickness of 2.5 mm. Resin sheet. The foamable resin composition comprises 65 parts by weight of low-density polyethylene (produced by Sumitomo Mitsui Polyolefin Company, trade name LE520), 35 parts by weight of ethylene-vinyl acetate copolymer (produced by Mitsui-DuPont Polymer Chemical Company) , trade name is EVAFLEX EV460, and vinyl acetate content is 19 weight %), the barium sulfate of 150 weight parts (Takehara Chemical Company produces, trade name is W-1), the azodicarbonamide of 4 weight parts (Otsuka Chemical Company Production, trade name UNIFOAM AZ SO-40) and 1 part by weight of zinc stearate (manufactured by Sakai Chemical Company, trade name SZ-2000) as a foaming aid

[0038] The foamable resin sheet was irradiated with electron beams of 2....

Embodiment 2

[0040] Obtain the sound-insulating material according to the method similar to embodiment 1, difference is: barium sulfate is adjusted to 100 weight parts by 150 weight parts, and azodicarbonamide is adjusted to 3 weight parts by 4 weight parts, and zinc stearate is adjusted to 3 weight parts by 1 The weight part was adjusted to 0.8 weight part. The apparent density of the sound insulation material obtained is 0.31g / cm 3 , and its thickness is 3.6mm. The resin expansion ratio of the polyolefin resin constituting the thermoplastic foamed resin sheet was 559.7%.

Embodiment 3

[0042] Obtain the sound-insulating material according to the method similar to embodiment 1, difference is: barium sulfate is adjusted to 50 weight parts by 150 weight parts, and azodicarbonamide is adjusted to 2 weight parts by 4 weight parts, and zinc stearate is adjusted to 2 weight parts by 1 The weight part was adjusted to 0.6 weight part. The apparent density of the sound insulation material obtained is 0.32g / cm 3 , and its thickness is 3.7mm. The resin expansion ratio of the polyolefin resin constituting the thermoplastic foamed resin sheet was 411.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com