Capsule staining of bacteria

A dyeing method and technology for bacterial capsules, applied in biochemical equipment and methods, microbial determination/inspection, etc., can solve problems such as experimental failure, high requirements for operating skills, and incompetence for novices, to reduce the difficulty of operation and achieve high efficiency. Dyeing method, the effect of maintaining integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] 1) Put a small drop of sterile water on the slide;

[0060] 2) Tablet preparation: use an inoculation loop to take a small amount of bacteria that has been cultured for 24 hours, and spread slowly from the center to the outside in a spiral shape in a water-wet state to keep the capsule intact;

[0061] 3) Natural air drying;

[0062] 4) Add a drop of pure methanol dropwise, fix for 1 minute, tilt and pour off the methanol;

[0063] 5) Add a few drops of phenol fuchsin and stain for 1 minute;

[0064] 6) Cover glass;

[0065]7) Carefully absorb the excess liquid around the coverslip with absorbent paper, tilt the slide and absorb part of the staining solution under the coverslip to increase the adhesion of the coverslip and the light transmittance of the sample during microscopic examination;

[0066] 8) Oil immersion microscope inspection.

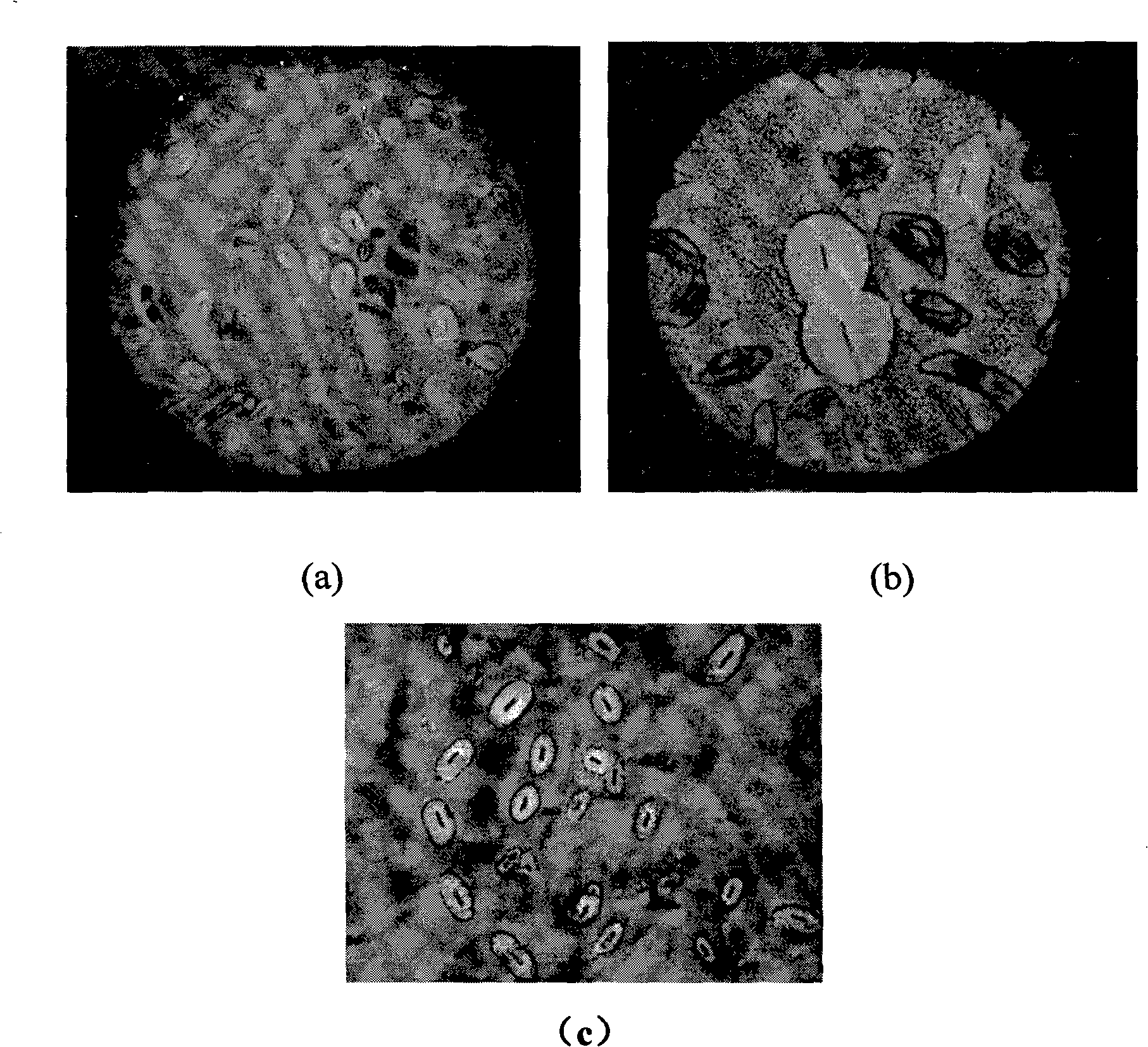

[0067] The observation results are attached figure 2 As shown in (a), the background is red and the capsule is colorless.

Embodiment 2

[0069] 1) Put a small drop of sterile water on the slide;

[0070] 2) Tablet preparation: use an inoculation loop to take a small amount of bacteria that has been cultured for 48 hours, and spread slowly from the center to the outside in a spiral shape in a wet state to keep the capsule intact;

[0071] 3) Natural air drying;

[0072] 4) Fix with pure methanol for 2 minutes, tilt and pour off the methanol;

[0073] 5) Add a few drops of phenol fuchsin and stain for 3 minutes;

[0074] 6) Cover glass;

[0075] 7) Carefully absorb the excess liquid around the coverslip with absorbent paper, tilt the slide and absorb part of the staining solution under the coverslip to increase the adhesion of the coverslip and the light transmittance of the sample during microscopic examination;

[0076] 8) Oil immersion microscope inspection. The observation results are attached figure 2 As shown in (b), the background is red and the capsule is colorless.

Embodiment 3

[0078] 1) Put a small drop of sterile water on the slide;

[0079] 2) Tablet preparation: use an inoculation loop to take a small amount of bacteria that has been cultured for 36 hours, and spread slowly from the center to the outside in a spiral shape in a wet state to keep the capsule intact;

[0080] 3) Natural air drying;

[0081] 4) Add 2 drops of pure methanol dropwise, fix for 1 minute, tilt and pour off the methanol;

[0082] 5) Add a few drops of phenol fuchsin for 2 minutes

[0083] 6) Cover glass;

[0084] 7) Carefully absorb the excess liquid around the coverslip with absorbent paper, tilt the slide and absorb part of the staining solution under the coverslip to increase the adhesion of the coverslip and the light transmittance of the sample during microscopic examination;

[0085] 8) Oil immersion microscope inspection. The observation results are attached figure 2 As shown in (c), the background is red and the capsule is colorless.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com