Single-component reaction type hot melt adhesives and steel plate composite material using the same

A technology of hot-melt adhesives and composite materials, which is applied in the field of steel plate composite materials to achieve the effects of excellent boiling water resistance, long coating life and excellent impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

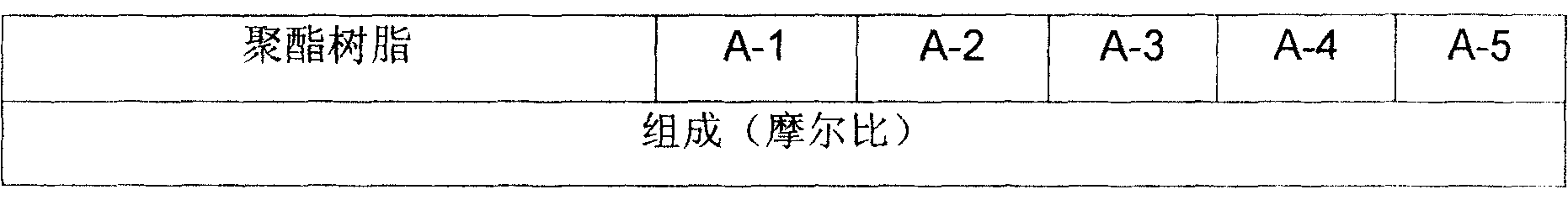

[0022] Synthesis Example 1 Synthesis Example of Polyester Resin

[0023] In a reaction kettle equipped with a stirrer, a thermometer, and a distillation condenser, add dibasic acid and dibasic alcohol according to the ratio of raw materials listed in Table 1, and carry out esterification reaction at 160°C to 230°C for 3 hours. Then, the pressure was reduced to 5 mmHg at 260° C. for 30 minutes, followed by polycondensation under high vacuum greater than 0.3 mmHg for 45 minutes to form an intermediate product. Then, return to normal pressure by introducing nitrogen gas. When the temperature of the reaction system drops to 210°C, add trimellitic anhydride and react for another 30 minutes. When the temperature of the reaction system drops to 110°C, add A-LinkTM35 according to the ratio in the table and react for 30 minutes. , to obtain polyester resins (A-1) to (A-5). The mass parts of their composition raw material consumption and the number average molecular weight of the polye...

Synthetic example 2

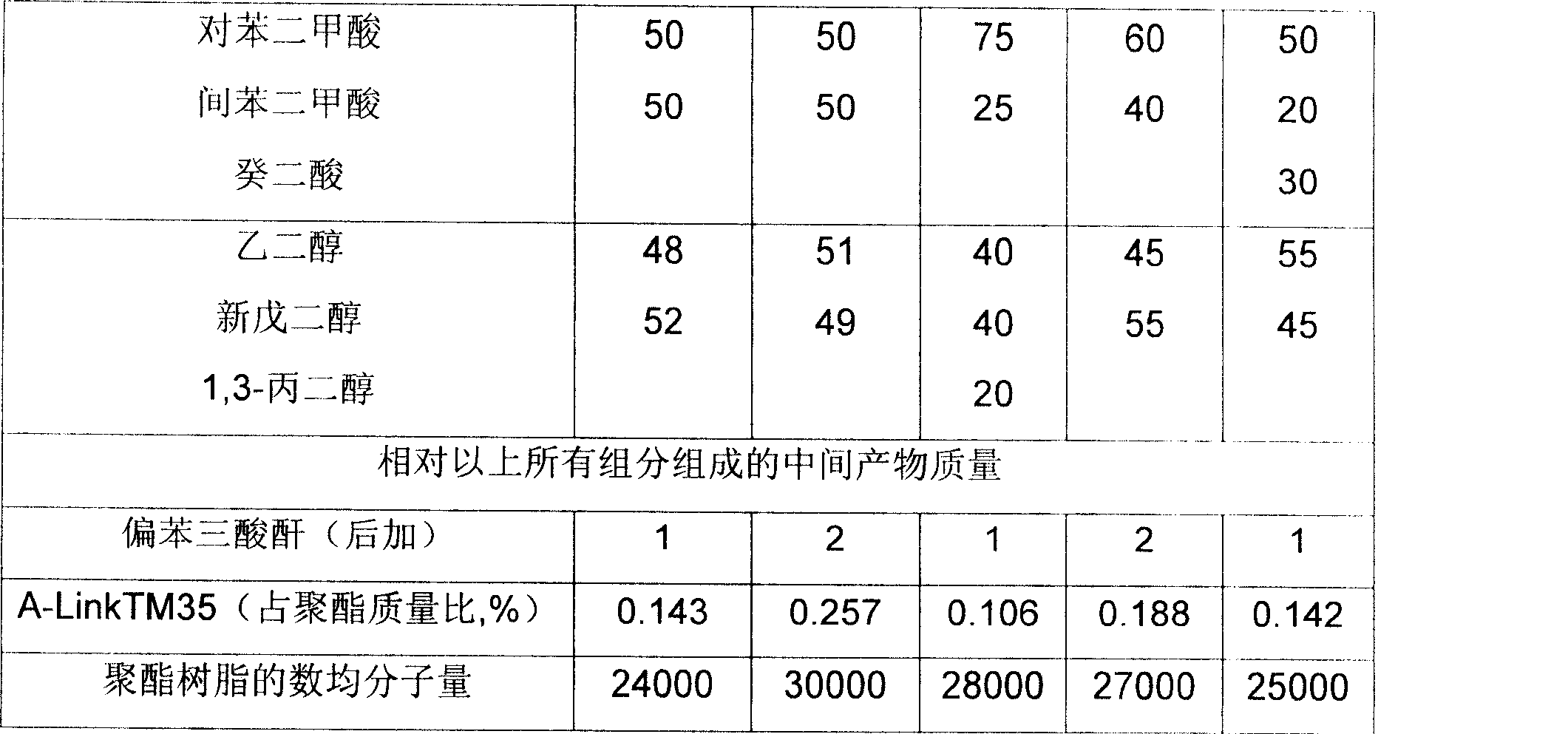

[0028] Synthesis Example 2 Synthesis Comparative Example of Polyester Resin

[0029] In a reaction kettle equipped with a stirrer, a thermometer, and a distillation condenser, add dibasic acid and dibasic alcohol according to the ratio of raw materials listed in Table 2, and carry out esterification reaction at 160° C. to 230° C. for 3 hours. Thereafter, the pressure was reduced to 5 mmHg at 260° C. over 30 minutes, followed by polycondensation under a high vacuum of 0.3 mmHg or less for 45 minutes to form an intermediate product. Then, nitrogen was introduced to return to normal pressure. When the temperature of the reaction system dropped to 210°C, trimellitic anhydride was added and reacted for another 30 minutes. When the temperature of the reaction system dropped to 110°C, A-LinkTM35 was added in proportion and reacted for 30 minutes to prepare Polyester resins (B-1) to (B-4) were obtained. The mass parts of their raw material consumption and the number average molecular...

Embodiment 1

[0034] Dissolve 100 parts of polyester resin (A-1) in 35 parts of ethyl acetate, 5 parts of butyl acetate, 25 parts of methyl ethyl ketone, 15 parts of toluene, 10 parts of isopropanol, 5 parts of ethylene glycol monomethyl In the mixed solvent of ether and 5 parts of ethylene glycol monobutyl ether, epoxy resin, curing agent and chloroacetic acid resin were added according to the quantities listed in Table 3. After fully mixing, they were coated on 25 μm polyester film, polychloride On the corona-treated surface of the vinyl film, the film thickness after drying was about 3 μm. Dry with hot air at 100°C for 2 minutes to remove the solvent, laminate the adhesive surfaces of the polyester film and the polyvinyl chloride film with the steel plates heated at 170°C in advance, and press them with a hot roller at 200°C to obtain polyvinyl chloride films respectively. Ester film, PVC composite steel plate. The obtained composite steel plate material was subjected to various perform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com