Technique for producing propenoic acid by dehydrating biomass lactic acid

A production process and technology of acrylic acid, applied in the field of chemical industry, can solve the problems of staying, no industrialized report, no acrylic acid process design research, etc., to meet the needs of industrialization and have the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

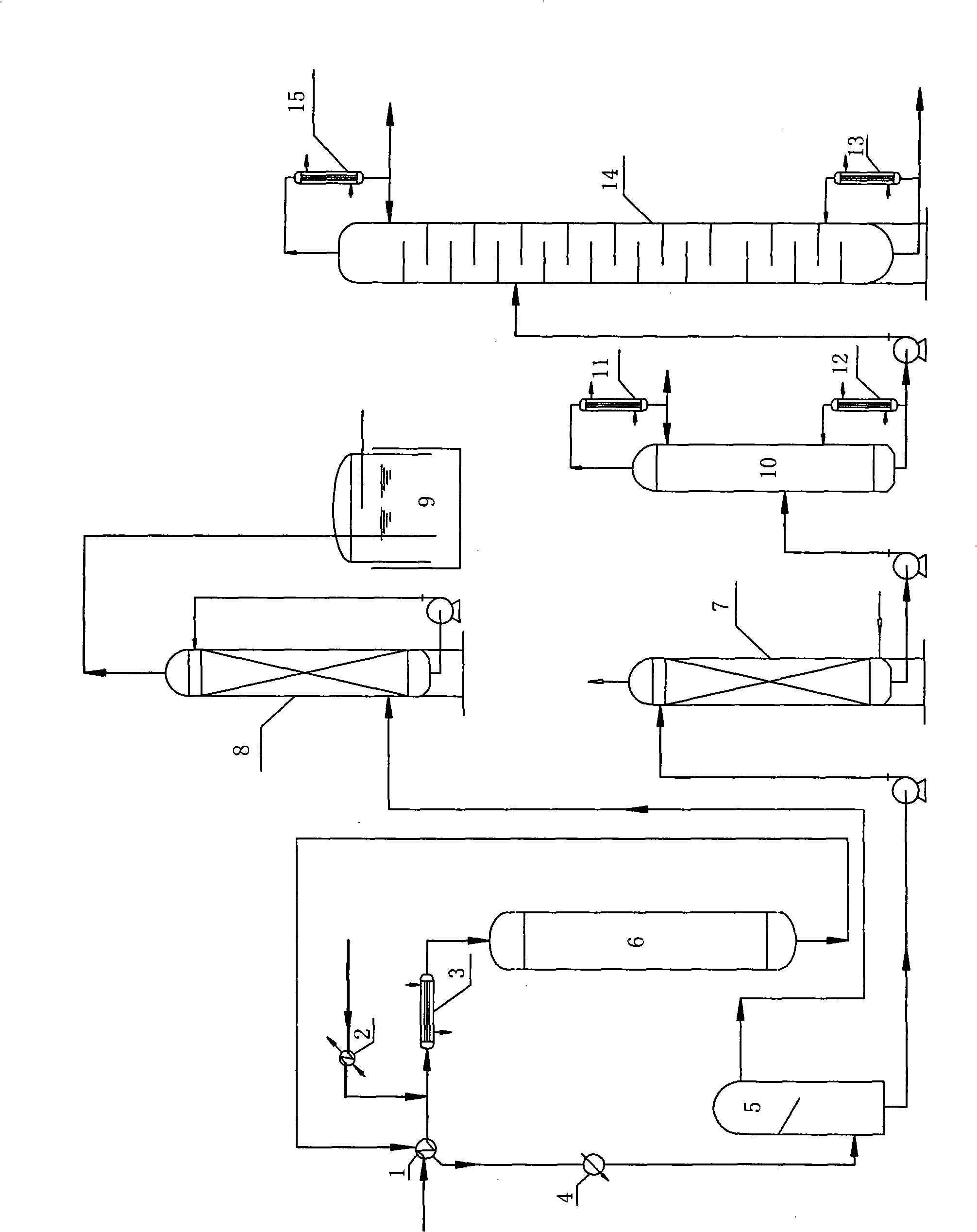

Method used

Image

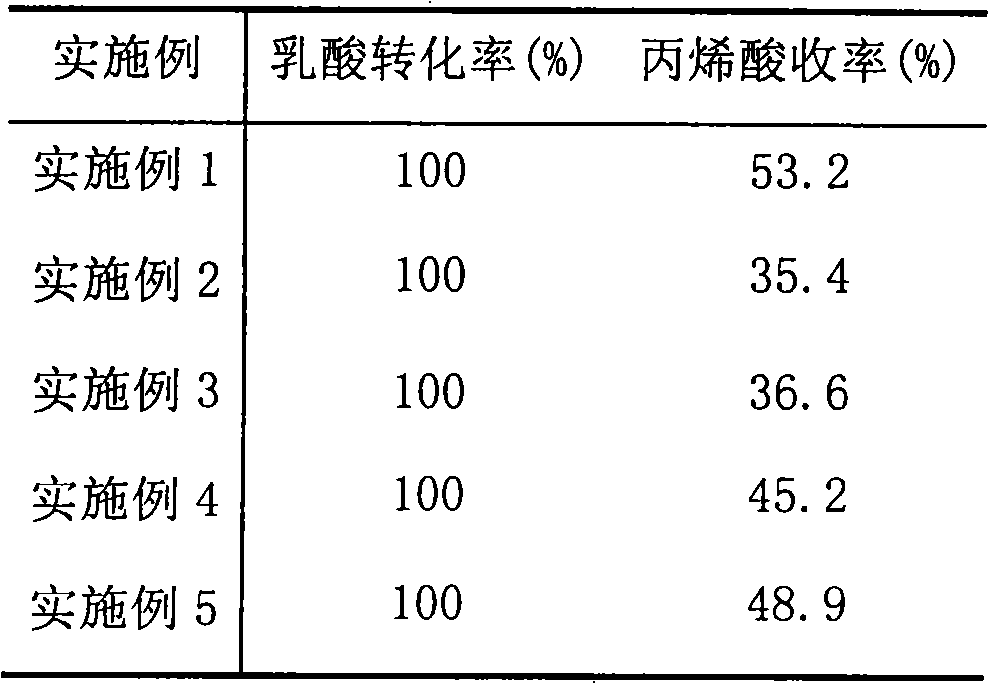

Examples

Embodiment 1

[0021] (1) The lactic acid aqueous solution with a mass fraction of 50% is passed through the gas-liquid heat exchanger I1 to be vaporized to reach 180°C.

[0022] (2) Heat nitrogen to 180°C through heat exchanger II 2, and mix with lactic acid-water mixed steam. The mixed gas is heated to the required temperature of 350°C through heat exchanger III 3.

[0023] (3) The heated mixed gas enters the gas-solid catalytic reactor 6 for catalytic reaction and dehydration to obtain reaction product gas. Gas-solid catalytic reactor 6 adopts an isothermal tubular fixed-bed reactor with a tube diameter of 30mm and a length of 3000mm. The heating medium is molten salt. The catalyst uses 1.5kgK / Y molecular sieve, and the bulk density of the molecular sieve is 1.0g / ml , the catalytic reaction temperature is 350°C, and the mass space velocity of the raw material is 3.0h -1 , The reaction pressure is 1.5MPa. The production method of K / Y molecular sieve: 0.4532kgKNO 3 Mix it with 10kg NaY ...

Embodiment 2

[0029] (1) The gasification of the lactic acid aqueous solution with a mass fraction of 60% is coupled with the condensation of the product gas, that is, the lactic acid aqueous solution with a mass fraction of 60% directly passes through a gas-liquid heat exchanger with a product gas at a temperature of 350°C as a heat source I1 was heated to 160 °C.

[0030] (2) The nitrogen gas is heated to 160°C through the heat exchanger II 2 and mixed with the lactic acid-water mixed steam, and the mixed gas is heated to the required temperature of 250°C through the heat exchanger III 3.

[0031] (3) The heated mixed gas enters the gas-solid catalytic reactor 6 for catalytic reaction and dehydration to obtain reaction product gas. Gas-solid catalytic reactor 6 adopts an isothermal tubular fixed-bed reactor with a tube diameter of 30mm and a length of 3000mm. The heating medium is molten salt. The catalyst uses 1.5kgBa / Y molecular sieve, and the bulk density of the molecular sieve is 1.0g...

Embodiment 3

[0037] (1) The lactic acid aqueous solution with a mass fraction of 30% is passed through the gas-liquid heat exchanger I1 to be vaporized to reach 180°C.

[0038] (2) Carbon dioxide is heated to 200°C through heat exchanger II 2 and mixed with lactic acid-water mixed steam. The mixed gas is heated up to the required temperature of 450°C through heat exchanger III 3.

[0039] (3) The heated mixed gas enters the gas-solid catalytic reactor 6 for catalytic reaction and dehydration to obtain reaction product gas. The gas-solid catalytic reactor 6 is an adiabatic bed reactor, the catalyst is 1.5kg Ca / Y molecular sieve, the particle size of the molecular sieve is 70um, the catalytic reaction temperature is 450°C, and the reaction pressure is 0.1MPa. The production method of Ca / Y molecular sieve: 0.6587kgCa(NO 3 ) 2 Mix it with 10kg NaY molecular sieve in 20L of water, heat and stir at 80°C for 4h, dry in an oven at 100°C for 24h, put the dried powder in a muffle furnace and roas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com