Freshwater eukaryoticmicroalgae culture method

A cultivation method and technology for microalgae, applied in biochemical equipment and methods, unicellular algae, enzymology/microbiology devices, etc., can solve the problem of poor controllability, uncontrollability, insufficient utilization of sunlight by microalgae, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

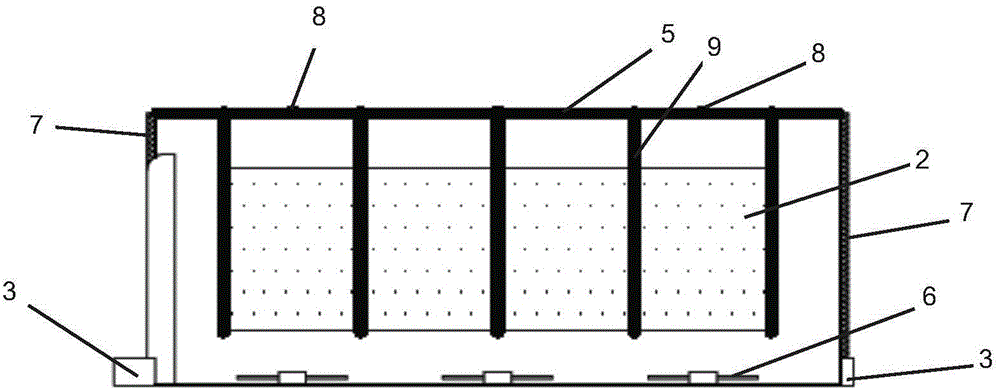

Image

Examples

Embodiment 1

[0127] Propagate microalgae in a small artificial light source test box, the selected algae species is Chlorella pyrenoidosa, and the inoculation concentration is 0.3g / L (dry weight). The artificial light source is a three-color LED light source, the wavelengths are 650±5nm, 440±5nm, 720±10nm, the ratio of the three-color light source is 10:3:2, the light intensity at the darkest part is about 3000lx, and the light and dark alternate time is 10 hours (bright): 2 hours (dark), the dark light power is about 40% of the bright light power. Introduce carbon dioxide, the pressure is 0.4Mpa, the pore diameter of the released ceramic membrane pressure tube is 10nm, the mixing ratio of carbon dioxide and air is 2%-3%, and the ventilation is continued until PH=6.5 to stop, reducing the mixing ratio of carbon dioxide and air , until the pH interval remains between 6.5-6.8. Breeding temperature is maintained at 27 degrees ± 1 degree.

[0128] The nutrient selection of culture fluid in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com