Method for preparing carbon nano-tube or rod by hydrothermal process

A technology of carbon nanotubes and hydrothermal method, applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., to achieve the effect of mild reaction conditions, wide application prospects, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

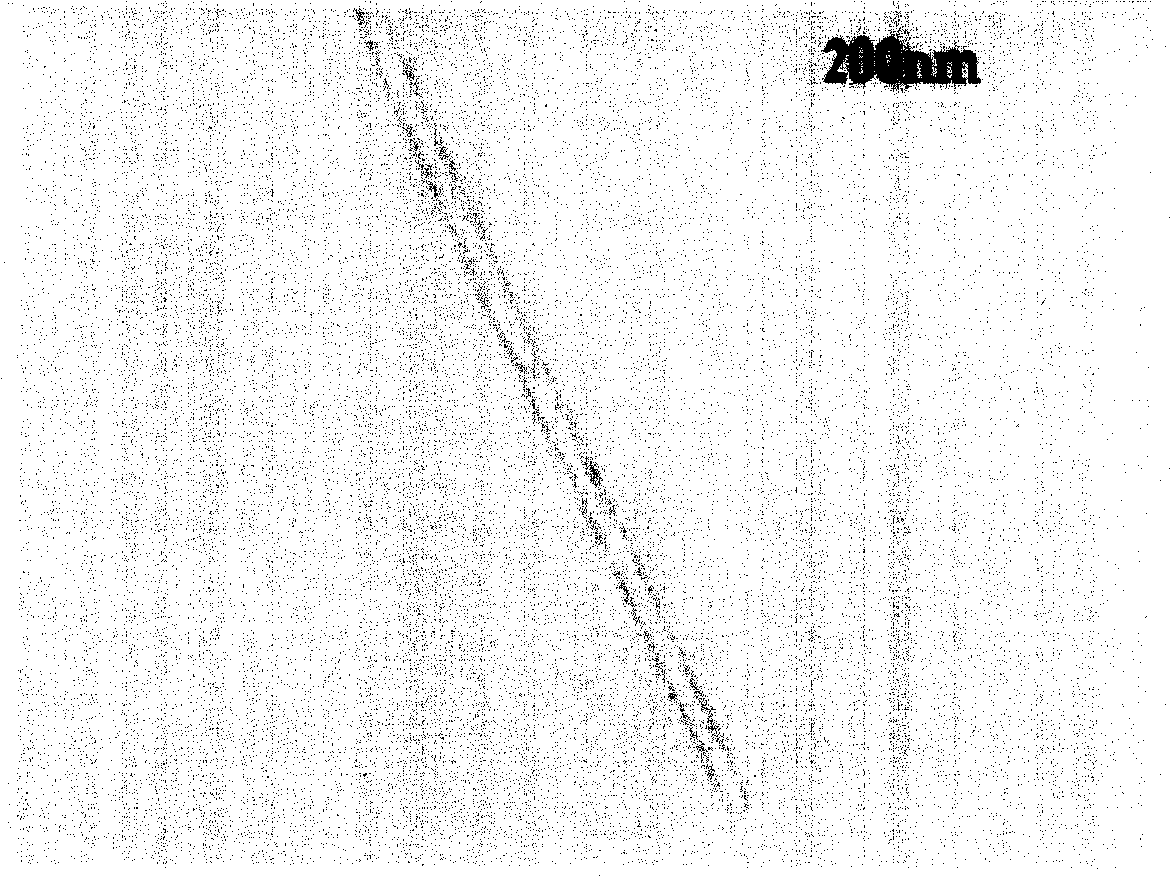

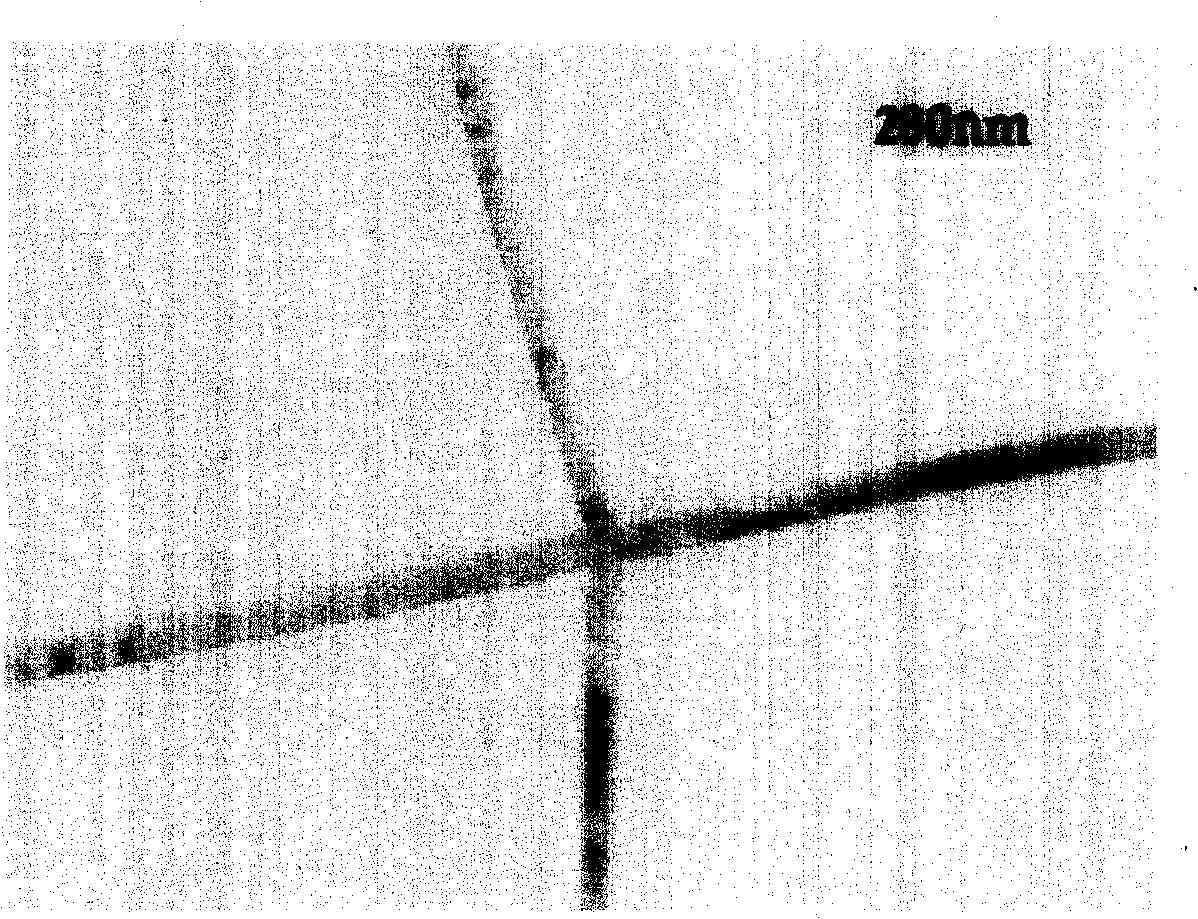

Image

Examples

Embodiment 1

[0025] Dissolve 1 gram of sucrose in 19 grams of 6mol / L H 2 SO 4 After fully stirring at room temperature to form a 5% sucrose acidic solution, it was transferred to a hydrothermal reaction kettle for hydrothermal reaction at 180°C for 12 hours, then naturally cooled to room temperature, centrifuged and washed repeatedly with deionized water After drying, carbon nanotubes with a diameter of 40-50 nm and a length of 1-2 μm can be obtained.

Embodiment 2

[0027] Dissolve 8 g of sucrose in 12 g of 7 mol / L H 2 SO 4 After fully stirring at room temperature to form a 40% sucrose acidic solution, transfer it to a hydrothermal reaction kettle, react hydrothermally at 150°C for 5 hours, then cool naturally to room temperature, centrifuge and wash repeatedly with deionized water After drying, carbon nanorods with a diameter of 30-50 nm and a length of 1-2 μm can be obtained.

Embodiment 3

[0029] Dissolve 2 grams of sucrose in 18 grams of 3mol / L H 3 PO 4 After fully stirring at room temperature to form a 10% sucrose acidic solution, transfer it to a hydrothermal reaction kettle for a hydrothermal reaction at 220°C for 24 hours, then naturally cool to room temperature, centrifuge and wash repeatedly with deionized water After drying, carbon nanorods with a diameter of 20-50 nm and a length of 0.5-2 μm can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com