Sizing drying machine

A dryer and sizing technology, applied in dryers, drying, progressive dryers, etc., can solve the problems of large water consumption, large emission of harmful gases from coal combustion, loss of power resources, etc. Small investment in production, favorable for popularization and implementation, safe and reliable in production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

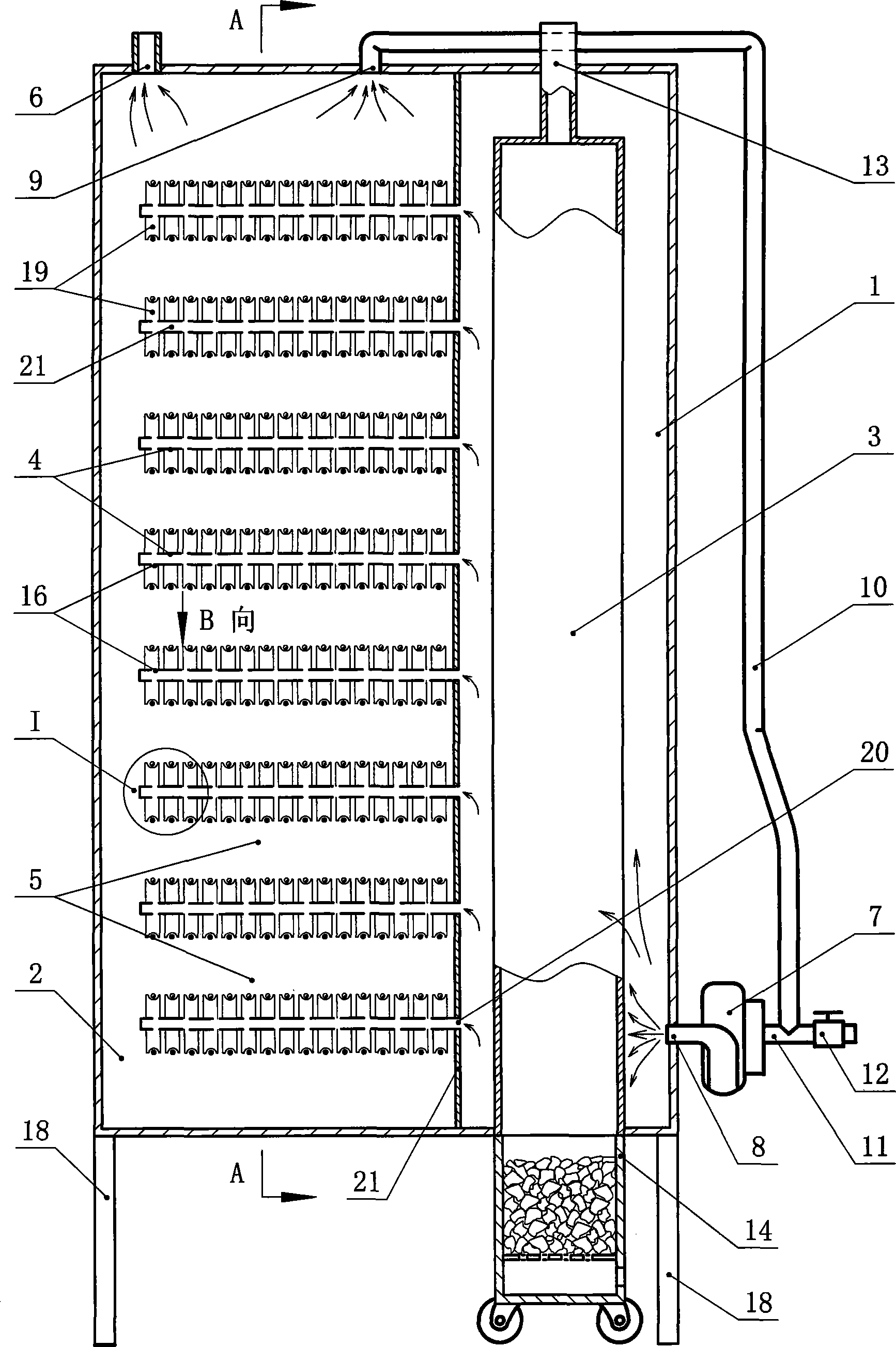

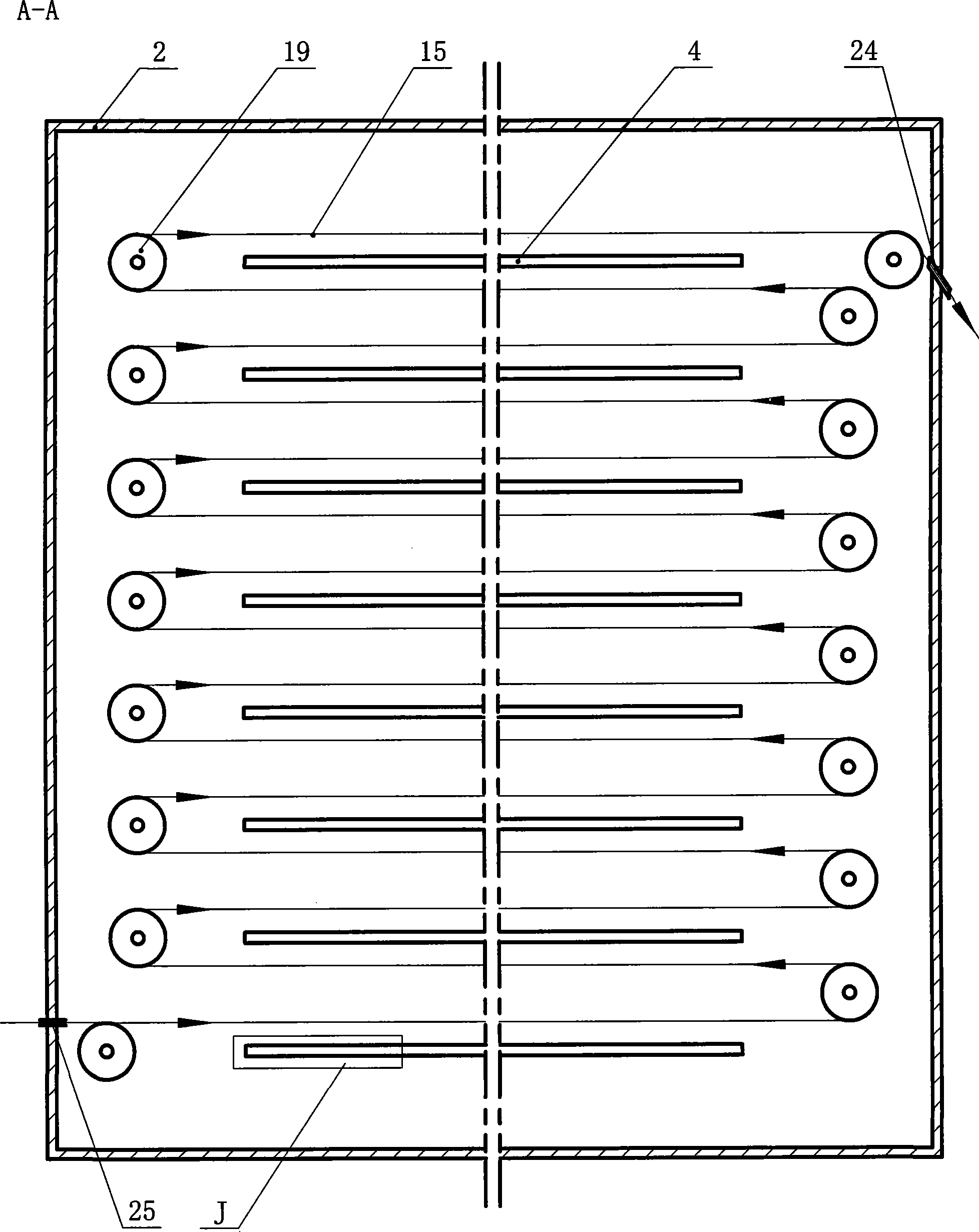

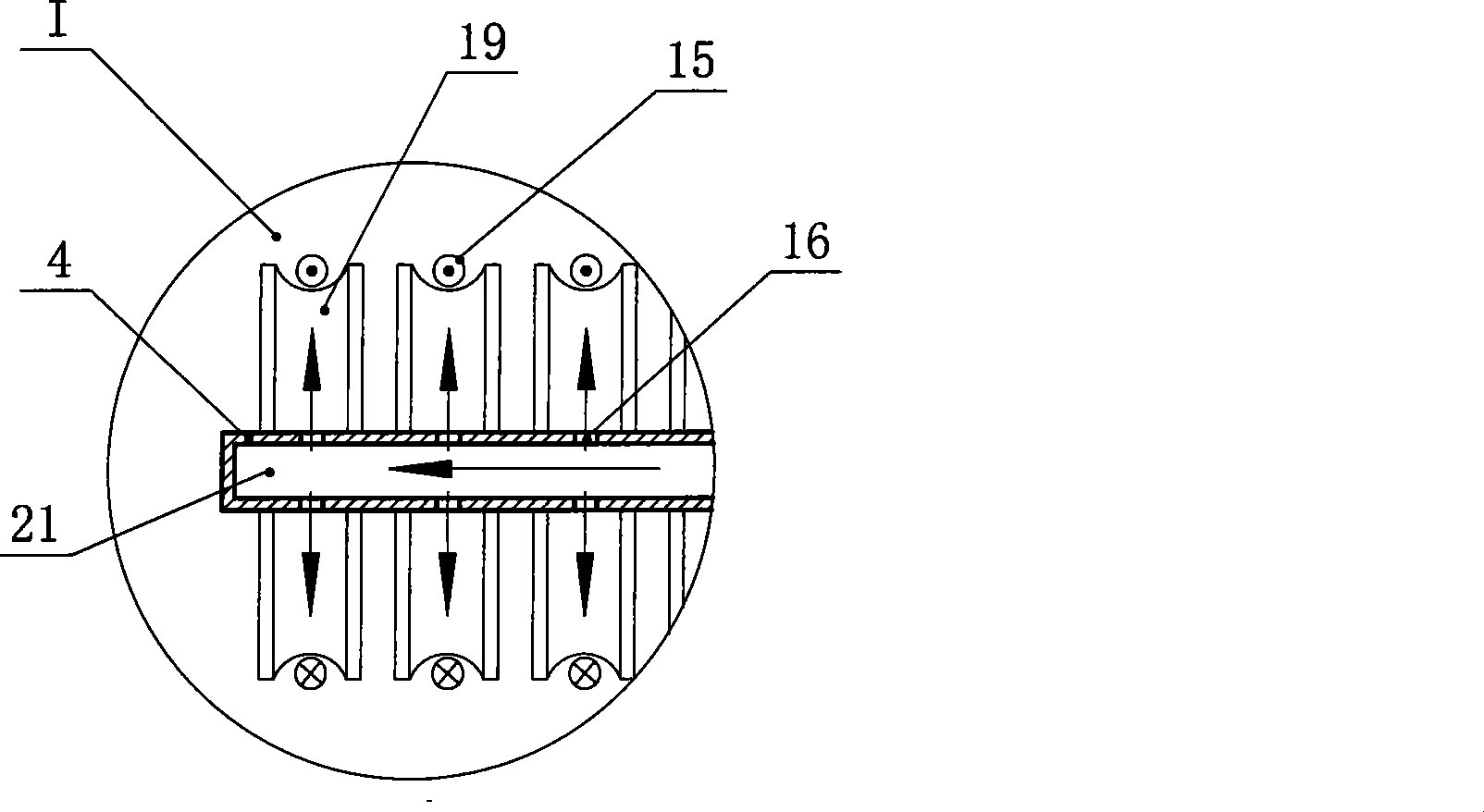

[0050] Embodiment one: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 ,Image 6, Figure 7 , Figure 8-1 , Figure 9-1 , Figure 14-1 , Figure 14-2 , a kind of sizing dryer, comprising interlayer heating box 1, drying box 2 and support 18 thereof, interlayer heating box 1 and drying box 2 are fixed as one, separated by a vertical partition 21 therebetween, A certain number of strip-shaped air inlets 20 are provided on the vertical partition 21, and a cooling device 3 is installed in the interlayer heating box 1, and an air inlet device is provided on the side wall of the interlayer heating box 1, and the air inlet device includes The blower fan 7 and the blower fan 7 air outlet are matched with the air inlet 8 at the lower end of the interlayer heating box 1 and communicated with each other. An exhaust hole 6 is arranged at the upper end of the drying box 2, and the exhaust hole 6 is used to discharge water vapor in the drying box 2. In addition, an air ...

Embodiment 2

[0054] Embodiment two: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 ,Image 6, Figure 7 , Figure 8-2 , Figure 9-1 , Figure 14-1 , Figure 14-2 , the numbers are the same as those in Embodiment 1, and the meanings are the same, and the same parts will not be repeated. The difference is that the cross-section of the cylinder of the heat sink 3 is circular.

Embodiment 3

[0055] Embodiment three: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 ,Image 6, Figure 7 , Figure 8-1 , Figure 9-2 , Figure 14-1 , Figure 14-2 , the numbering is the same as that of Embodiment 1, the meaning is the same, and the same parts will not be repeated. The difference is that the heat dissipation device 3 is a composite structure in which a certain number of vertical cylinders are connected to each other at their lower ends. This structure is convenient for using a stove Heating and easy installation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com