Dry-wet parallel air-cooling condenser washing system and washing cycle determining method thereof

A technology for air-cooled condensers and cleaning systems, which is applied in the direction of flushing, cleaning heat transfer devices, lighting and heating equipment, etc., and can solve the problems of high resource consumption and high cleaning costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below using the drawings and specific embodiments.

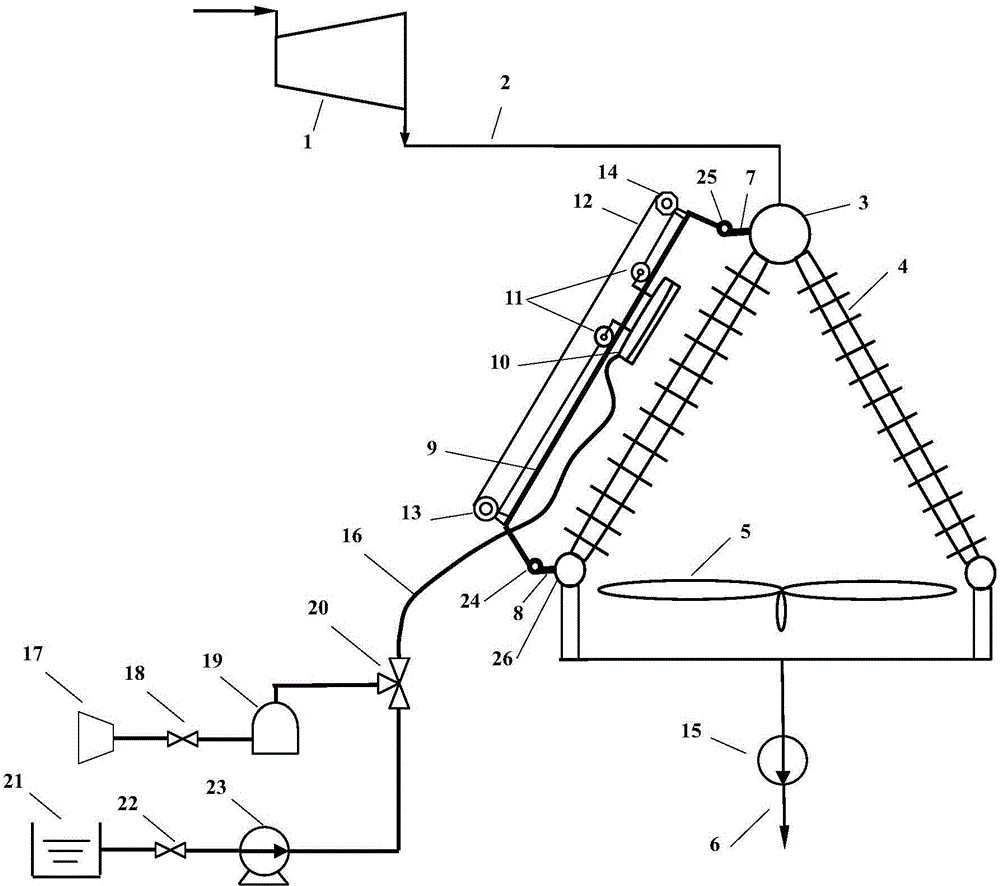

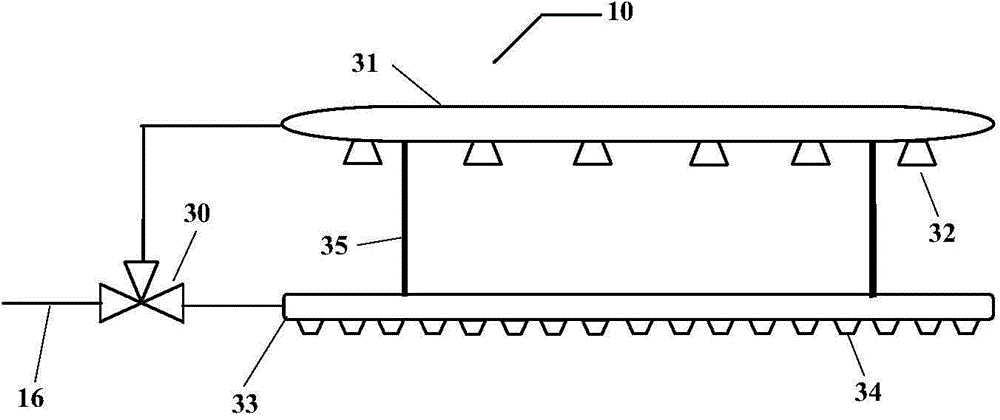

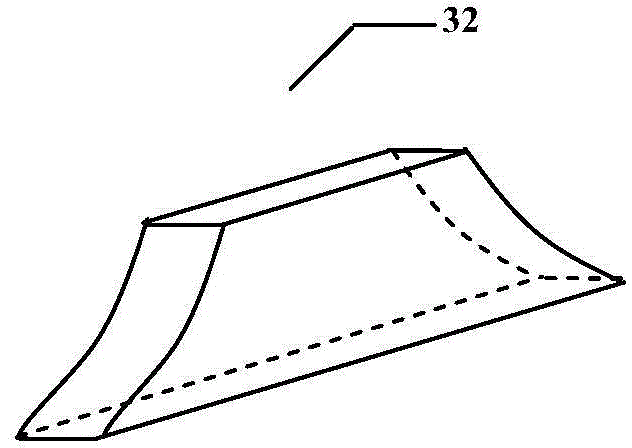

[0039] refer to figure 1 , the dry-wet parallel air-cooled condenser cleaning system includes the high-pressure air output end of the air compressor 17 connected to the input end of the high-pressure gas storage tank 19 through the first stop valve 18, and the output end of the high-pressure gas storage tank 19 is connected to the first three-way exchange The first input end of the valve 20 is connected; the output end of the desalinated water tank 21 is connected with the input end of the high-pressure water pump 23 through the second stop valve 22, and the output end of the high-pressure water pump 23 is connected with the second input end of the first three-way reversing valve 20; The output end of a three-way reversing valve 20 communicates with the mobile washer 10 through the air / water dual-purpose delivery pipe 16, and the mobile washer 10 is placed on the horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com