Aluminum alloy for air conditioner tube and method for manufacturing same

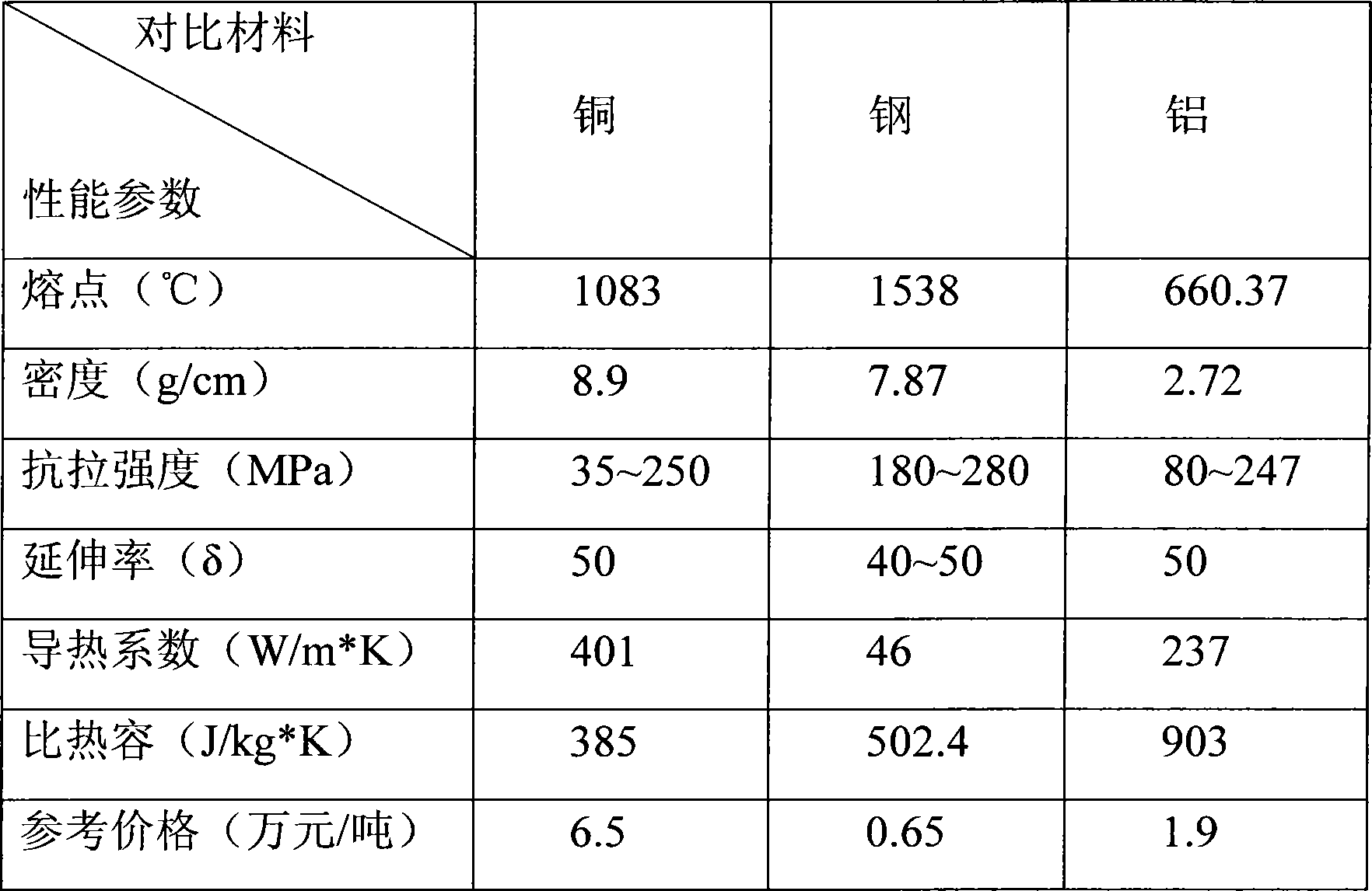

A manufacturing method and an aluminum alloy technology are applied to the aluminum alloy for air-conditioning pipes and the manufacturing field thereof, which can solve the problems of high price of copper air-conditioning pipes and poor performance of iron air-conditioning pipes, and achieve high tensile strength and excellent corrosion resistance. , the effect of high elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The raw materials are: primary aluminum ingot, pure magnesium ingot, pure zinc ingot, Al-10%Mn, Al-20%Fe, Al-40%Cu, Al-4%Zr, Al-10%Sr, Al-10%Ti , Al-5%Ti-1%B, Al-RE master alloy, the RE element is La-80%Ce mixed rare earth elements.

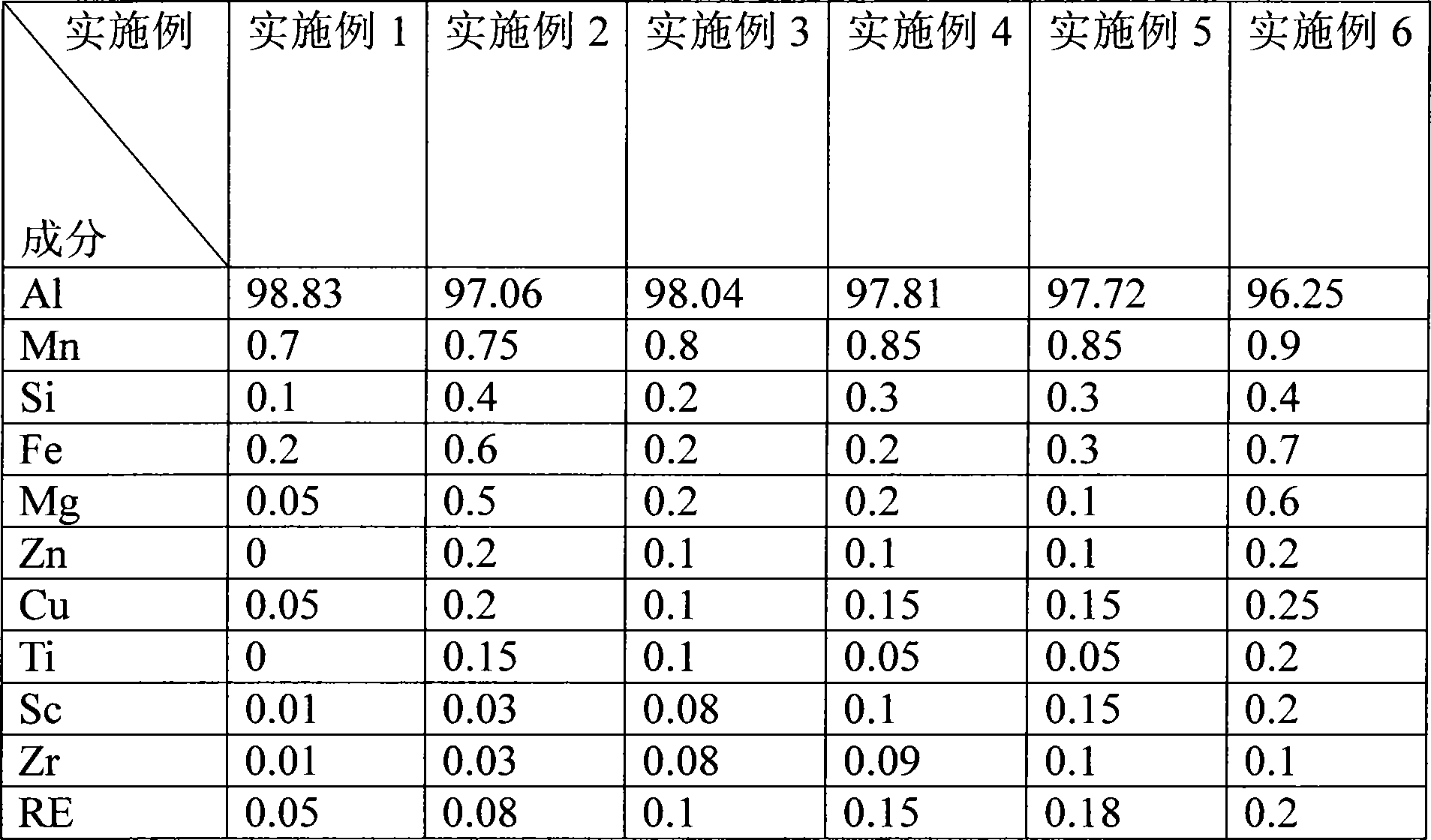

[0019] Select several kinds of raw material alloys, according to the ratio of each element in Table 1, and make aluminum alloys according to the general methods of aluminum alloy manufacturing such as smelting, refining, casting, advancing rolling, and finishing rolling.

[0020] The melting temperature is 720°C-730°C, the refining temperature is 700°C-710°C, the casting temperature is 690°C-700°C, the rolling temperature is 480°C-490°C, and the final rolling temperature is 280°C-290°C.

Embodiment 2

[0022] The raw materials are: primary aluminum ingot, pure magnesium ingot, pure zinc ingot, Al-10%Mn, Al-20%Fe, Al-40%Cu, Al-4%Zr, Al-10%Sr, Al-10%Ti , Al-5%Ti-1%B, Al-RE master alloy, the RE element is La-80%Ce mixed rare earth elements.

[0023] Select several kinds of raw material alloys, according to the ratio of each element in Table 1, and make aluminum alloys according to the general methods of aluminum alloy manufacturing such as smelting, refining, casting, advancing rolling, and finishing rolling.

[0024] The melting temperature is 720°C, the refining temperature is 700°C, the casting temperature is 690°C, the rolling temperature is 480°C, and the final rolling temperature is 280°C.

Embodiment 3

[0026] The raw materials are: primary aluminum ingot, pure magnesium ingot, pure zinc ingot, Al-10%Mn, Al-20%Fe, Al-40%Cu, Al-4%Zr, Al-10%Sr, Al-10%Ti , Al-5%Ti-1%B, Al-RE master alloy, the RE element is La-80%Ce mixed rare earth elements.

[0027] Select several kinds of raw material alloys, according to the ratio of each element in Table 1, and make aluminum alloys according to the general methods of aluminum alloy manufacturing such as smelting, refining, casting, advancing rolling, and finishing rolling.

[0028] The melting temperature is 750°C-760°C, the refining temperature is 720°C-730°C, the casting temperature is 710°C-720°C, the rolling temperature is 510°C-520°C, and the final rolling temperature is 310°C-320°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com